Multi-point tracking data optimization method for automatic inspection equipment

An automatic inspection and data tracking technology, which is applied in the direction of electrical digital data processing, special data processing applications, complex mathematical operations, etc., can solve the problems of limited application range, reduce the workload of power grid inspection operations, and difficult automatic inspection, etc. Achieve the effect of reducing external interference and improving data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present application will be described in detail below with reference to specific embodiments.

[0030] In the process of large-area and long-distance inspection operations, the use of various ground and flight equipment to realize automatic inspection data collection can effectively reduce the manual workload, and can easily conduct inspection operations in poor or dangerous areas. Due to the limitation of the positioning accuracy of the existing equipment, most of the current automatic inspection equipment still requires the operator to operate within a short or medium distance to improve the efficiency of the control feedback as much as possible, so as to achieve the positioning of the inspection equipment at a longer distance. Detection is the basis for enabling longer-range telemetry control.

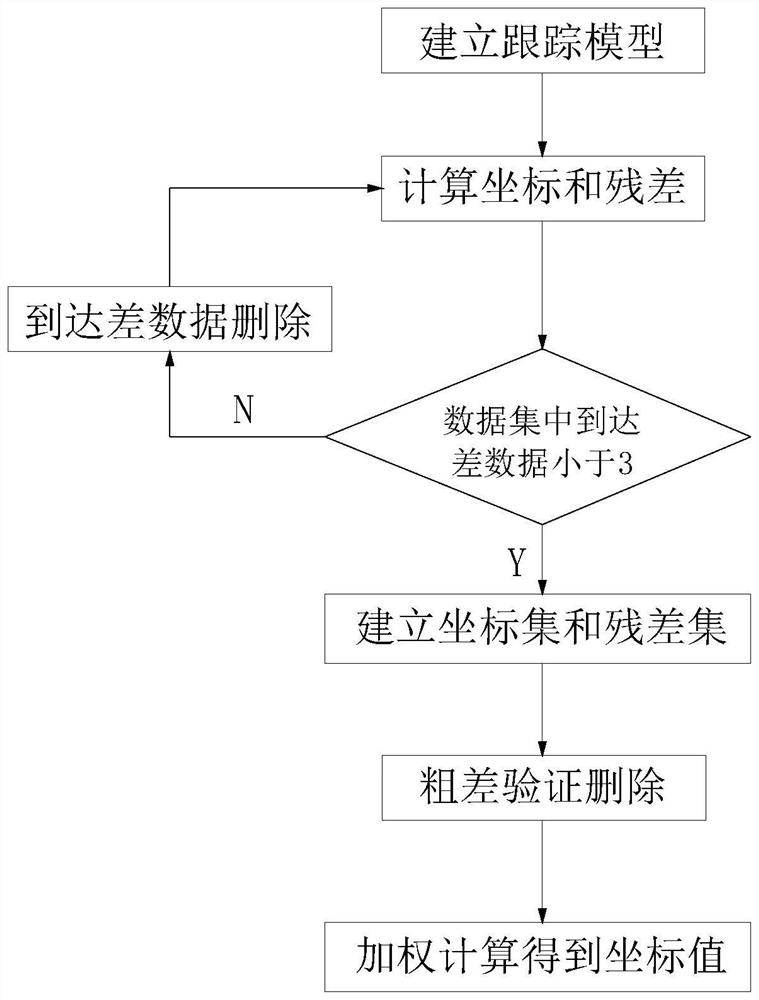

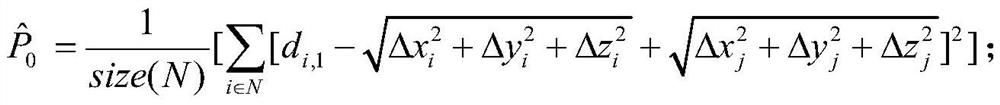

[0031] To this end, the present application provides a device suitable for automatic inspection of power grids in combination with the existing chan arrival difference po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com