Underwater hydraulic oil cylinder anti-oil-spilling and waterproof structure and method

A technology of hydraulic cylinder and waterproof structure, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc. Small, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

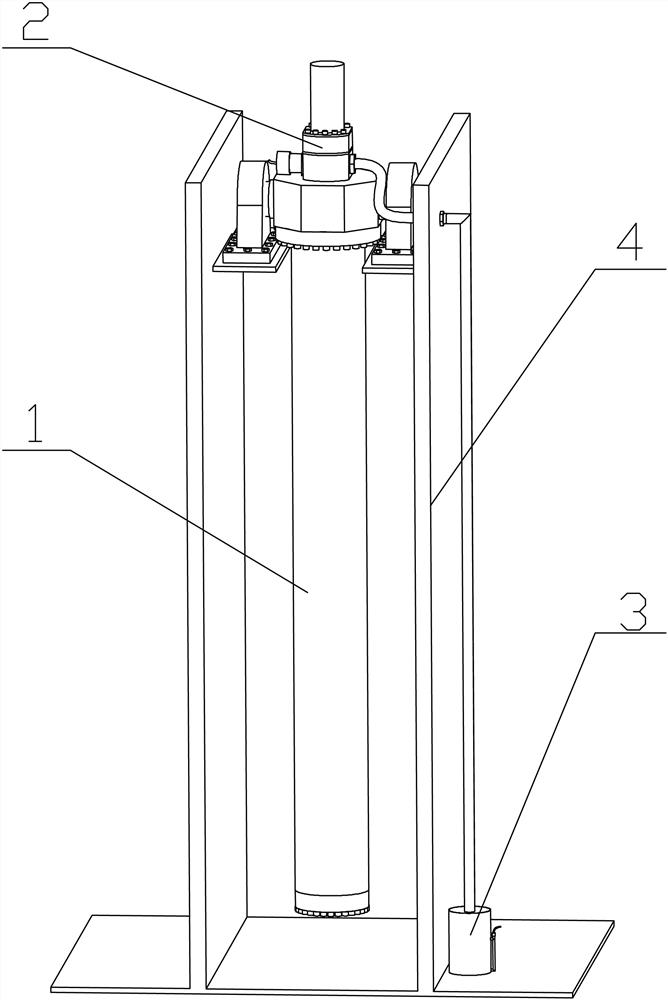

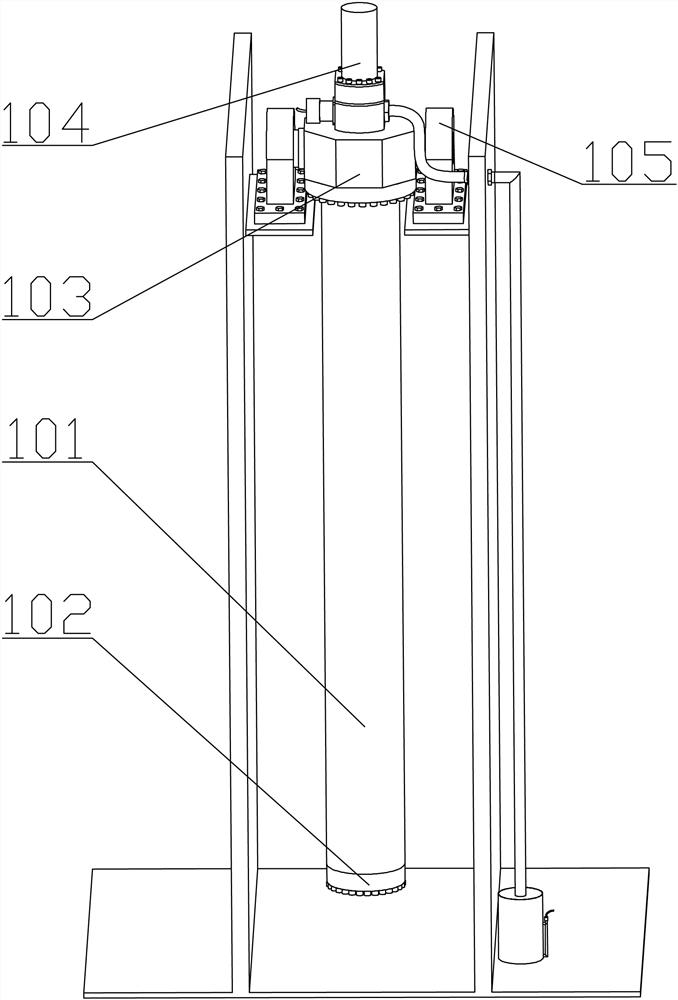

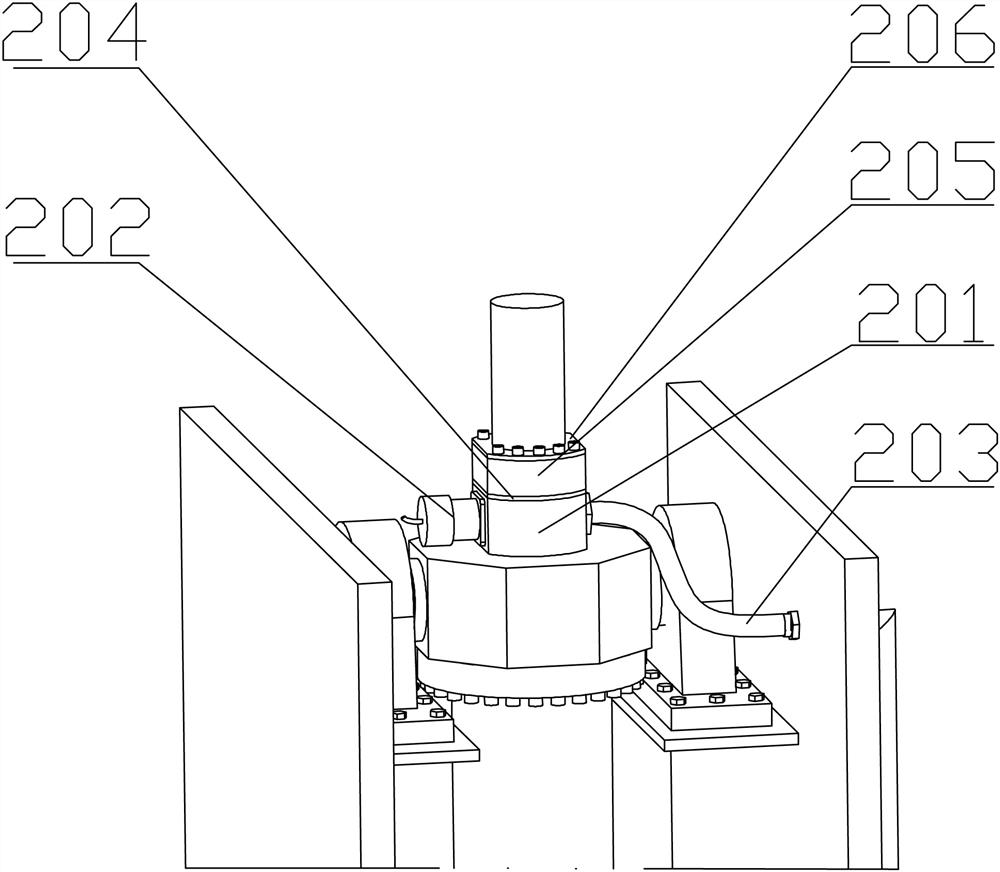

[0034] see Figure 1-5 , an underwater hydraulic oil cylinder anti-spill and waterproof structure, which includes a hydraulic oil cylinder 1, the hydraulic oil cylinder 1 is fixedly installed on the water blocking door body 4, and the top of the hydraulic oil cylinder 1 is installed with an anti-spill and water-proof end for preventing oil spills and water leakage. The cover 2 and the oil-spill-proof and waterproof end cover 2 are connected with the oil-water monitoring and alarm device 3 . Through the provided anti-spill and waterproof end cover 2, the forward sealing end cover 201 and the reverse sealing end cover 205 of the oil cylinder form a bidirectional sealing combined structure, so as to prevent the hydraulic oil of the hydraulic cylinder from flowing into the surrounding water and prevent the surrounding water from flowing into the hydraulic cylinder the goal of.

[0035]Further, the hydraulic oil cylinder 1 includes a cylinder body 101, an upper end cover 102 is in...

Embodiment 2

[0043] The method for preventing oil spilling and waterproofing of a hydraulic oil cylinder with an oil-spill prevention and waterproof structure for an underwater hydraulic cylinder includes the following steps:

[0044] Step 1: The hydraulic cylinder 1 working underwater is in a normal state. When the piston and the piston rod 104 perform the retracting action, the cylinder stroke detection sensor 202 transmits the action position signal of the hydraulic cylinder 1 to the control station through the cable. The upper chamber of the hydraulic cylinder 1 The pressure is in a high pressure state, the pressure in the inner cavity of the cylinder forward sealing end cover 201 is always zero. Leakage; the inner cavity pressure of the forward sealing end cover 201 of the cylinder is always zero, which is less than the water pressure in the surrounding environment of the hydraulic cylinder 1, and the V-shaped seal in the reverse sealing end cover 205 is also in normal working conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com