Unsealing device and unsealing method for flip chip device

A flip-chip and device technology, which is applied in the direction of cleaning methods using liquids, machine tools suitable for grinding workpiece planes, chemical instruments and methods, etc., to achieve the effect of improving grinding efficiency

Active Publication Date: 2022-06-10

合肥鑫丰科技有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] When grinding the substrate, the chip will be placed on the grinding table first, and then the substrate will be polished with a grinder, but the existing grinding method is generally Gradually grind the substrate along one direction. This method makes the chip slide due to the friction of the grinder when grinding the chip, which affects the grinding efficiency. In addition, during the grinding process, the grinding depth of the grinder will decrease. Changes due to the movement of the chip, resulting in uneven grinding of the substrate by the grinding device, and careless operation will cause damage to the chip

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

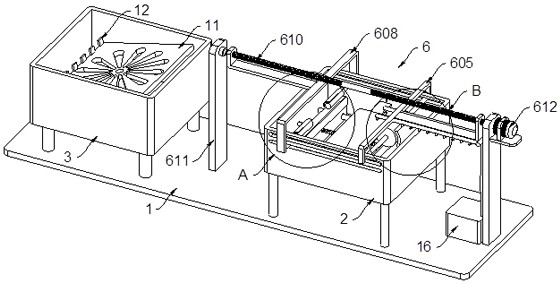

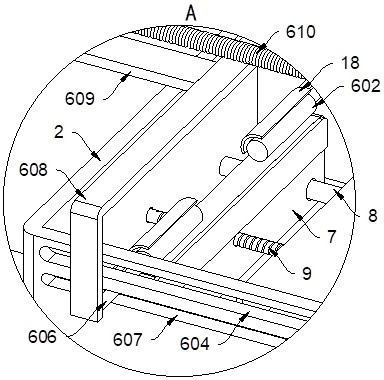

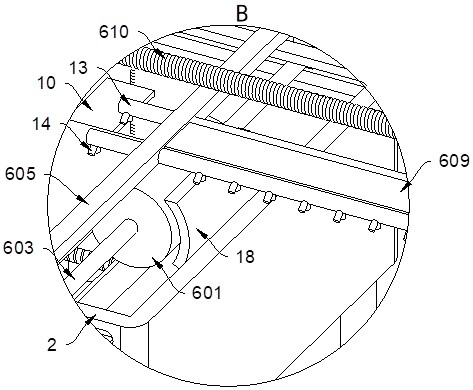

The invention belongs to the technical field of semiconductors, and particularly relates to an unsealing device and unsealing method for a flip chip device.The unsealing device comprises a base, a polishing box and a cleaning box are arranged at the top of the base, a plurality of supporting legs are fixedly connected to the bottom of the polishing box and the bottom of the cleaning box, a supporting plate is arranged in the polishing box, and the supporting legs are fixedly connected to the bottom of the cleaning box. An adjusting device is arranged at the bottom of the supporting plate, a grinding device is arranged at the top of the supporting plate, and clamping plates are arranged on the two sides of the supporting plate. The polishing device is arranged, in the process of polishing the base plate, a first electric polishing roller and a second electric polishing roller are driven by a third screw to polish the base plate from two opposite directions at the same time, and due to the fact that the rotating directions of the first electric polishing roller and the second electric polishing roller are opposite, the polishing effect is good; therefore, friction force generated by the first electric grinding roller and the second electric grinding roller on the base plate can be counteracted, and it is guaranteed that the base plate cannot slide in the grinding process.

Description

technical field [0001] The invention belongs to the technical field of semiconductors, and in particular relates to an unsealing device and an unsealing method for flip-chip devices. Background technique [0002] A flip chip is a leadless structure that typically contains circuit elements. Flip-chip is to deposit tin-lead balls on the I / O pad, and then flip the chip to heat and use the molten tin-lead balls to combine with the ceramic substrate. This technology replaces conventional wire bonding and gradually becomes the mainstream of packaging in the future. It is currently mainly used in high-time packaging. Mainly CPU, GPU and Chipset products. In order to detect the product quality of the flip chip, it is necessary to unseal the flip chip. The existing unsealing method is to use a grinding device to polish the substrate on the flip chip, and then use hydrofluoric acid to bond the substrate and the chip. The glue used is removed so that the chip can be completely separa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B27/033B24B7/07B24B27/00B24B41/06B24B47/12B24B47/16B24B47/20B08B3/04

CPCB24B27/033B24B7/07B24B27/0076B24B41/068B24B41/06B24B47/12B24B47/16B24B47/20B08B3/04

Inventor 陈昱宏

Owner 合肥鑫丰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com