Compression hydraulic buffer structure

A technology of hydraulic buffering and compression holes, which is applied in the direction of liquid shock absorbers, spring/shock absorbers, shock absorbers, etc., can solve the problem that the performance of the shock absorber cannot be responded accordingly, the damping coefficient cannot be changed, and the shock absorption is reduced Performance and other issues, to achieve the effect of improving shock absorption and buffering effect, smooth transition of force value, and increasing damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

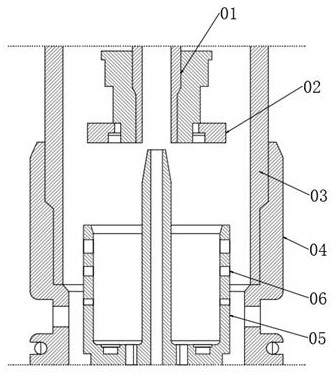

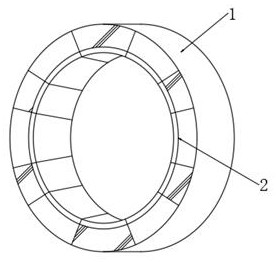

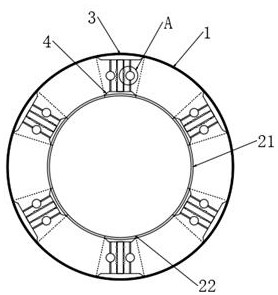

[0041] see Figure 1-3 , a compressed hydraulic buffer structure, including a piston rod 01, a buffer piston 02, an oil storage cylinder 03, a connection base 04 and a hydraulic buffer assembly 05, the buffer piston 02 is installed on the lower end of the piston rod 01, and the oil storage cylinder 03 is installed on the connection Inside the base 04, the hydraulic buffer assembly 05 is installed on the inside of the oil storage cylinder 03 and corresponds to the piston rod 01. The hydraulic buffer assembly 05 is provided with multiple sets of uniformly distributed compression holes 06 from top to bottom, and the compression holes 06 are inlaid and connected with The matching support ring 1, the inner end of the support ring 1 is fixedly connected with the internal variable ring 2, the internal variable ring 2 includes a plurality of staggered shaped segments 21 and external expansion segments 22, the area of the support ring 1 corresponding to the external expansion segment ...

Embodiment 2

[0043] see Figure 4 , between the inner positioning seat 3 and the outer positioning seat 4, a plurality of evenly distributed internal pressure drum covers 7 are arranged, and a pair of symmetrically distributed pull rods 8 are inserted in the internal pressure drum cover 7, and the pull rods 8 are connected to the inner positioning seat 3 respectively. It is fixedly connected with the outer positioning seat 4, the outer end of the thermal expansion rod 5 is also sleeved with an elastic heat preservation sleeve 6, the hollow structure is filled with deionized water, and a plurality of water-cooled capsules 9 are arranged in the internal pressure drum cover 7, and the thermal expansion rod 5 After being heated and expanded to a certain extent, the pull rod 8 will be used to pull the internal pressure drum cover 7, thereby squeezing and breaking the water-cooled capsule 9, and triggering the cooling action to cool the oil. The elastic insulation cover 6 can temporarily isolate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com