Forklift load weight measuring system and method based on lifting hydraulic cylinder pressure measurement

A technology of weight measurement and hydraulic cylinder, applied in the field of forklift load measurement system based on pressure measurement of lifting hydraulic cylinder, can solve the problems of difficult engineering realization, complex three-phase asynchronous motor model, difficult realization of load weight, etc., so as to facilitate engineering realization. , low cost, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific implementations.

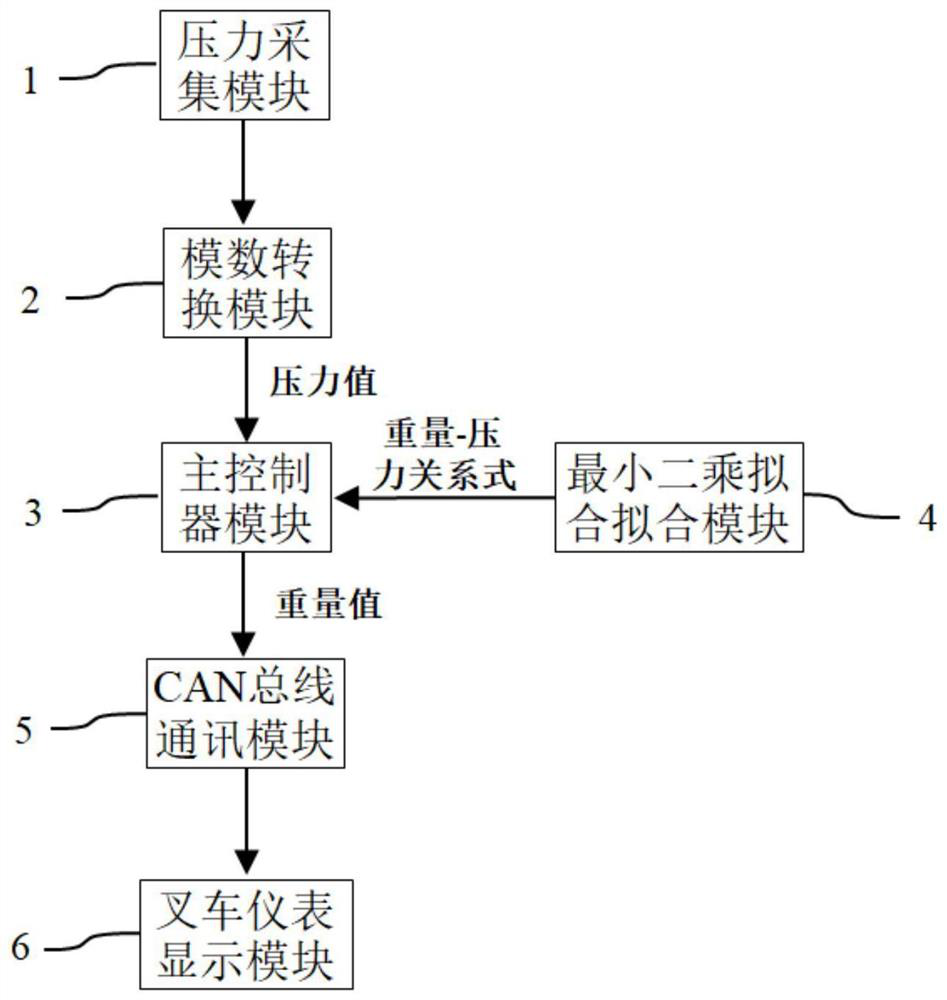

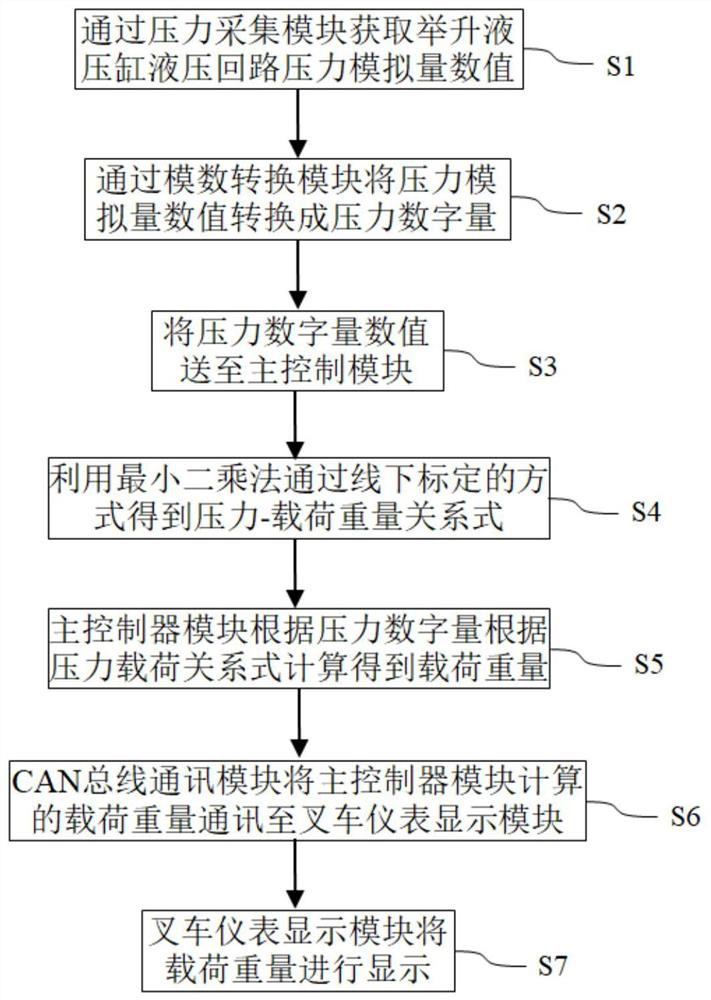

[0044] like figure 1 The load weight measurement component 1 includes a pressure acquisition module 1, an analog-to-digital conversion module 2, a main controller module 3, a least squares fitting module 4, a CAN bus communication module 5, and a forklift instrument display module 6; pressure acquisition module 1 is connected to the main controller module 3 through the analog-to-digital conversion module 2, the main control module 3 is connected to the forklift instrument display module 6 through the CAN bus communication module 5, and the least squares fitting module 4 is an offline software module for The pressure-load relationship is obtained by calculation, and the pressure-load relationship is programmed into the main controller module 3 through software programming.

[0045] In the specific implementation, the main controller module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com