Acrylic polyurethane synthesis reactor

A technology of acrylic polyurethane and synthetic reactors, which is applied in chemical/physical/physical-chemical mobile reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., and can solve the problem of increasing cleaning personnel's damage to the inner wall of the synthetic cylinder Difficulty in cleaning, insufficient stirring of acrylic polyurethane emulsion, reduction of synthesis rate of acrylic polyurethane, etc., to achieve the effect of increasing synthesis rate and synthesis effect, reducing cleaning difficulty, and improving stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

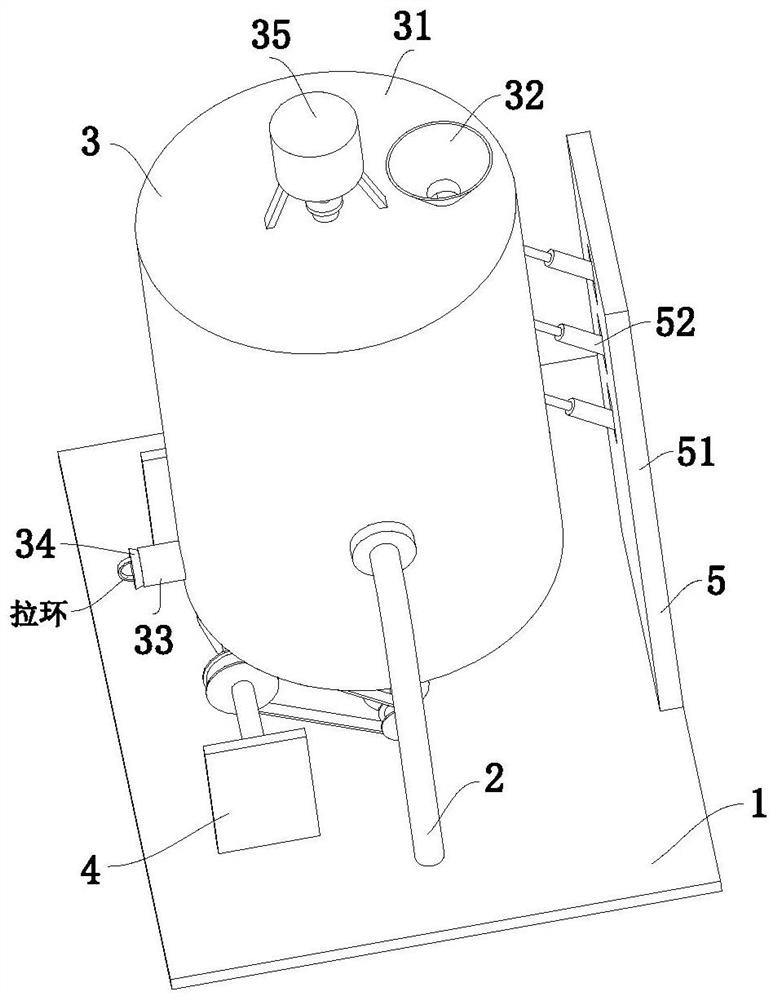

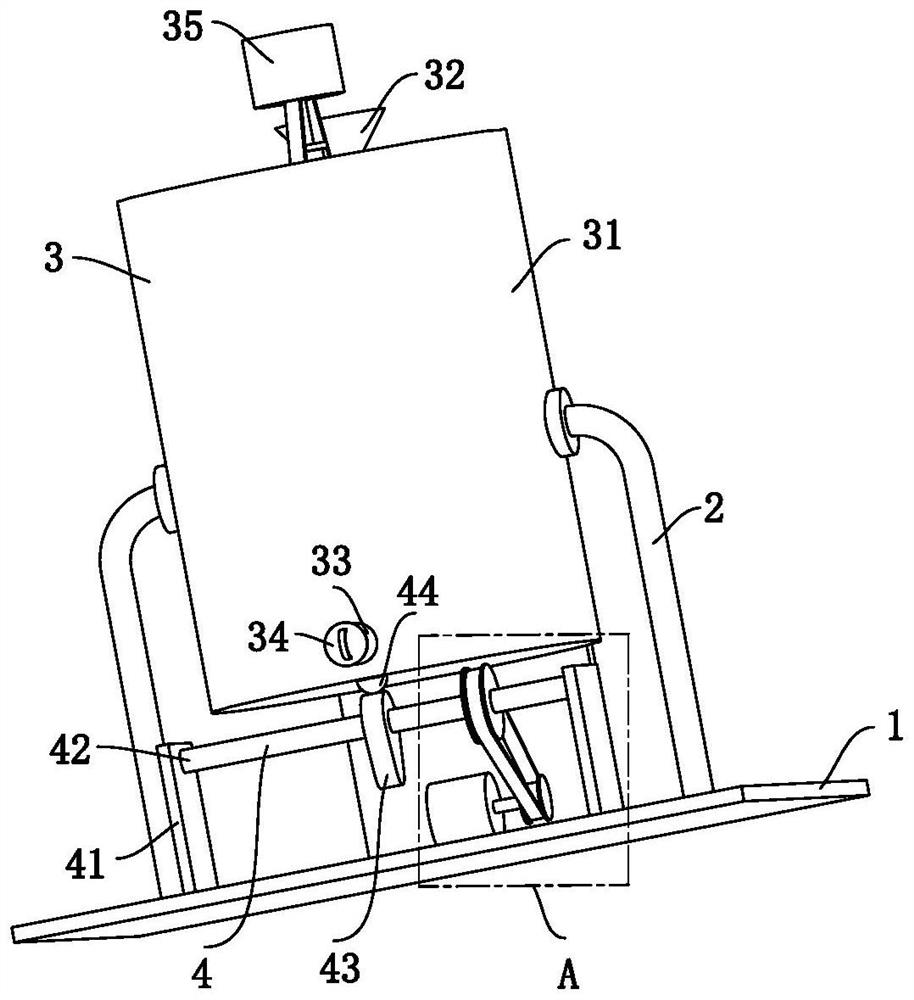

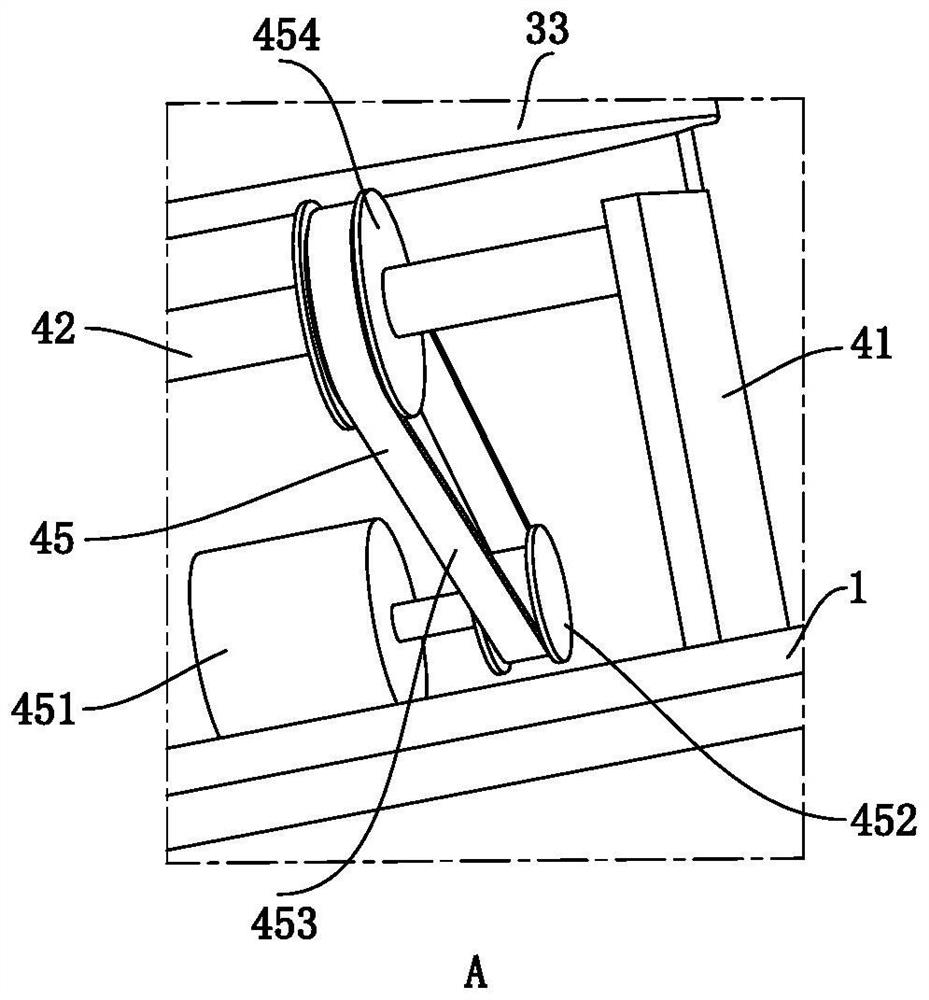

[0030] refer to Figure 1 to Figure 8 , an acrylic polyurethane synthesis reactor, comprising a bottom plate 1, a support rod 2, a synthesis component 3, a vibrating component 4 and a buffer component 5, the support rod 2 is symmetrically installed in the middle of the upper end of the bottom plate 1, and the upper end of the support rod 2 is rotationally connected There is a synthesis part 3, a vibration part 4 is arranged under the synthesis part 3, the lower end of the vibration part 4 is installed on the bottom plate 1, and a buffer part 5 is connected to the right side of the synthesis part 3;

[0031]The synthesis component 3 includes a synthesis cylinder 31, a feeding funnel 32, a discharge pipe 33, a rubber plug 34, an agitation unit 35, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com