Graphite-containing gold ore analysis method and sample roasting effect analysis equipment thereof

A technology of analysis equipment and analysis method, which is applied in the preparation of test samples, analysis of materials, chemical analysis by titration, etc. It can solve the problems of low accuracy of gold element analysis and incomplete roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

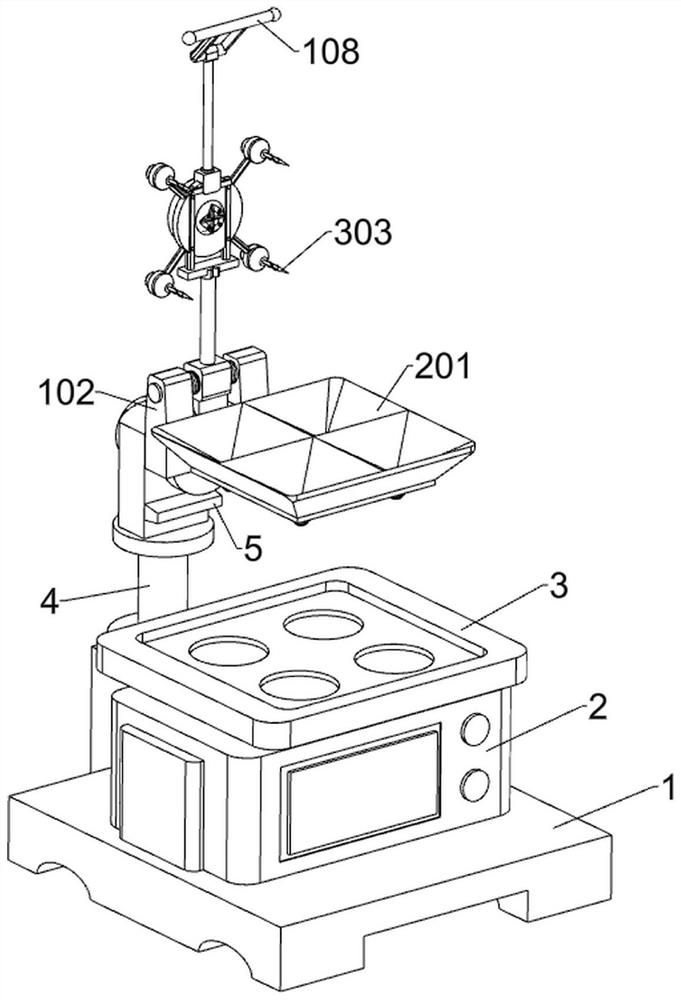

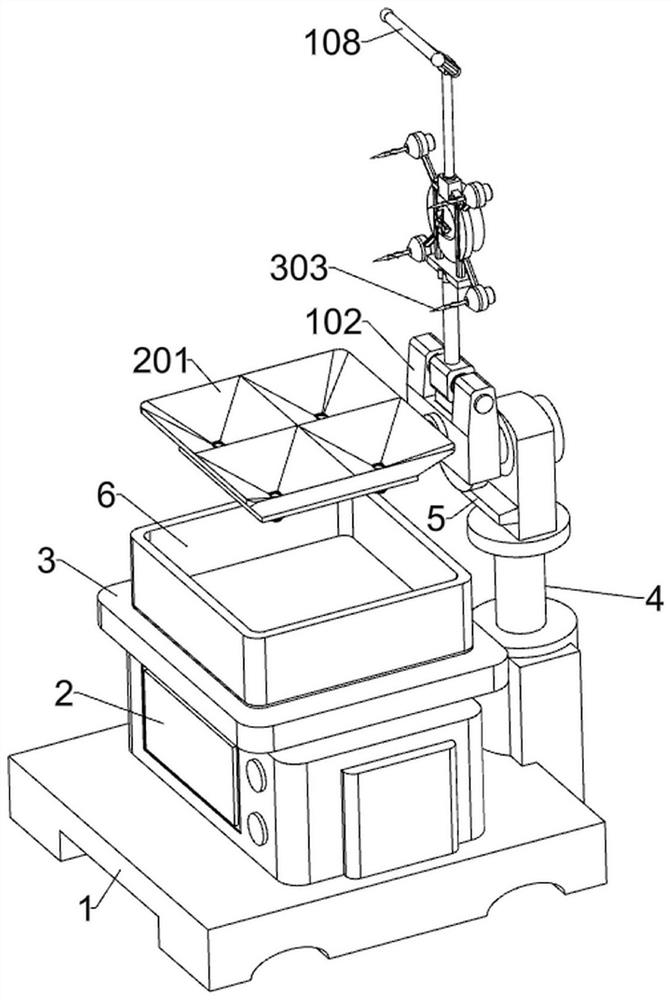

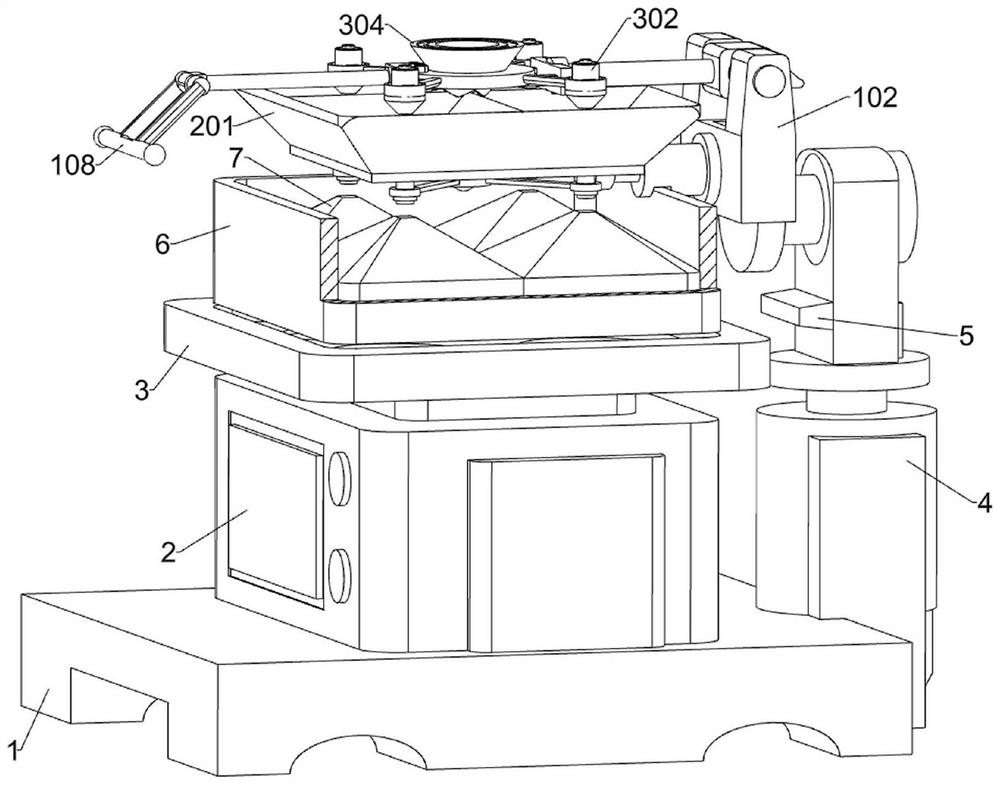

[0036] A kind of equipment for analyzing the roasting effect of graphite-containing gold ore samples, such as Figure 1-Figure 11 As shown, it includes an angle adjustment unit, a sieving unit, a grinding unit, a base 1, a weighing instrument 2, a weighing plate 3, a lifting part 4 and a clamping block 5; a weighing instrument 2 is fixed on the upper side of the base 1; A weighing plate 3 is fixedly connected to the upper side of the weighing instrument 2; a lifting member 4 is fixedly connected to the rear side of the base 1; a clamping block 5 is fixedly connected to the front side of the lifting end of the lifting member 4; An angle adjustment unit is connected; the front side of the angle adjustment unit is connected with a screening unit; the upper side of the angle adjustment unit is connected with a grinding unit.

[0037] like Figure 1-Figure 6 As shown, the angle adjustment includes a first electric rotating shaft 101, a first mounting frame 102, a second electric r...

Embodiment 2

[0048] like Figure 1-Figure 13 As shown, this embodiment is further optimized on the basis of Embodiment 1, and also includes a fine sieve assembly, the sample dividing tube 203 is provided with a fine sieve assembly, and the fine sieve assembly includes an elastic sheet 401 and an annular plug 402; An elastic sheet 401 is fixed to the lower edge of the sample splitting tube 203 ; an annular plug 402 is fixed to the outer surface of the elastic sheet 401 .

[0049] After the operator puts the crucible 6 back on the weighing pan 3, the annular plugs 402 at the ends of the four elastic sheets 401 are buckled into the lower ends of the four sample dividing tubes 203 respectively, such as: Figure 13 shown, followed by completion as Figure 4 The change shown works, so that the crucible 6 is buckled upside down above the sample dividing plate 201. During the sliding process of the sample 7 along the sample dividing tube 203, the sample 7 needs to pass through the annular plug 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com