Frost crack prevention device for water supply pipe fitting equipment

A technology for water supply pipe fittings and anti-freeze cracking, which is applied to water supply devices, water supply main pipelines, water supply pipeline systems, etc., which can solve the problems of high processing cost, short service life, and poor pressure resistance function, and achieve low processing and use costs. The effect of long life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

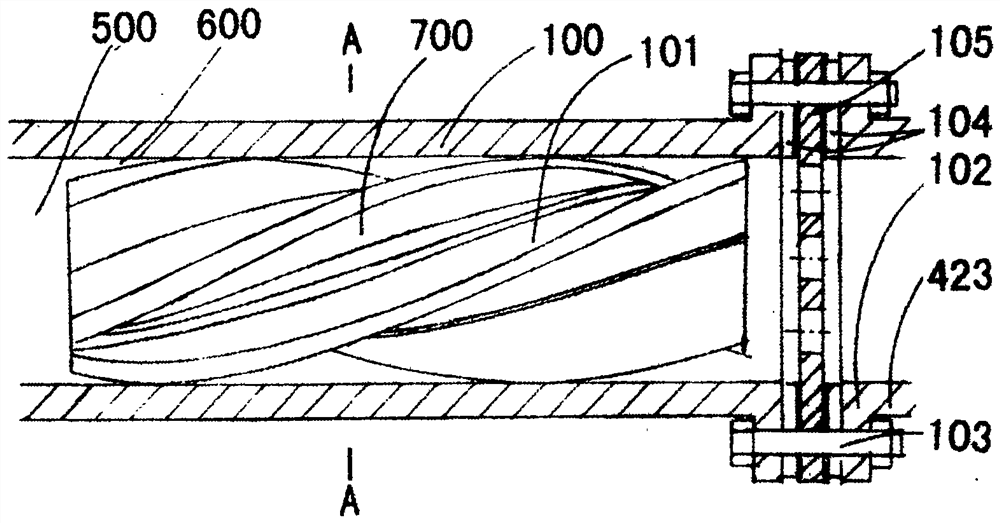

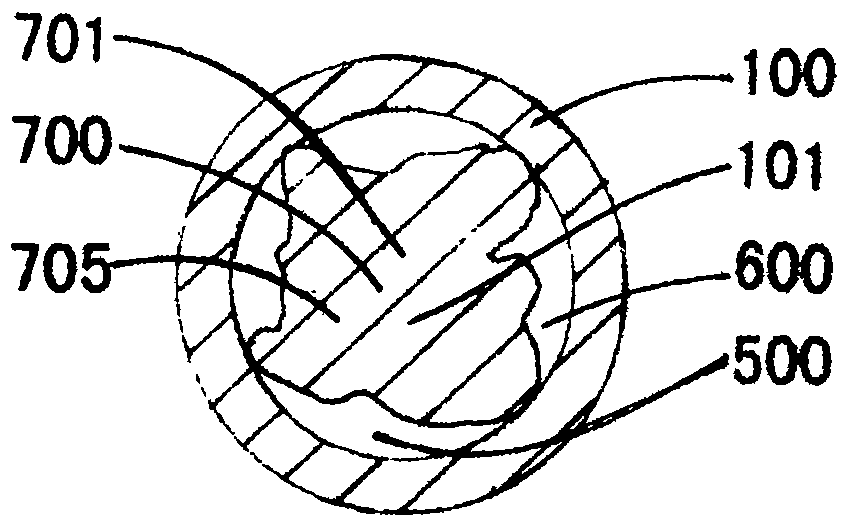

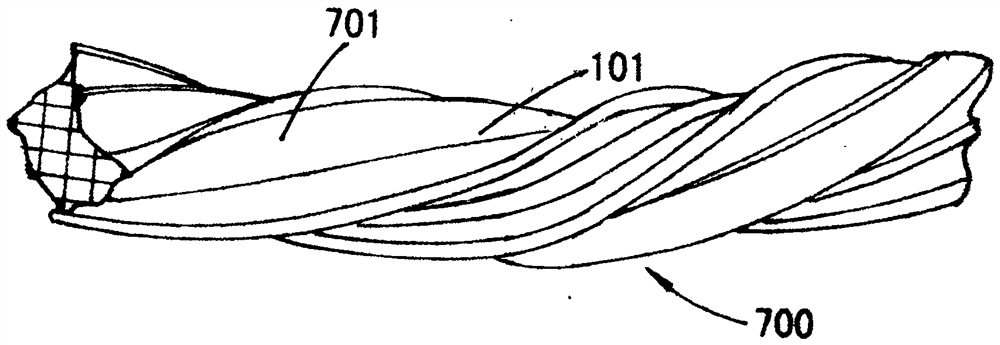

[0090] Figure 1 to Figure 24 Among them, the pressing rubber body 700 includes a pressing rubber strip 421 for water meters, a pressing rubber strip 101 for pipes, a pressing rubber strip 309 for faucets, a pressing rubber strip 701, a pressing rubber sheet 410 for water meters, and the pressing rubber sheet 702. The pressure rubber ball 211 for the valve, the pressure rubber ball 308 for the faucet, the pressure rubber ball 703, the pressure rubber block 704, and the pressure rubber layer 705 are all elastic, soft, and non-water immersed. , Can offset pressure, good recovery, its interior is solid rubber body, especially silicone rubber body, non-toxic, tasteless. The solid abutting rubber body 700 is obtained by using a well-known mature rubber processing technology, which will not be described here.

[0091] Figure 1 to Figure 17 , which is also the anti-freeze cracking device of the water pipe of the present invention, the section of the pressing rubber strip 101 is of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com