Self-aligning roller bearing used based on stirring equipment

A technology of self-aligning roller bearing and stirring equipment, which is applied in rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of reducing the service life of the bearing, the heat cannot be dissipated in time, and the service life of the bearing is shortened, so as to prolong the service life. life, improve heat dissipation effect, improve service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

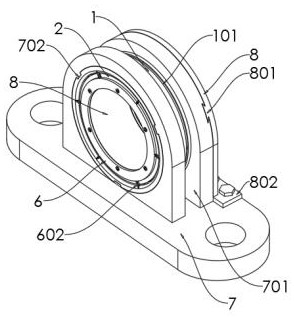

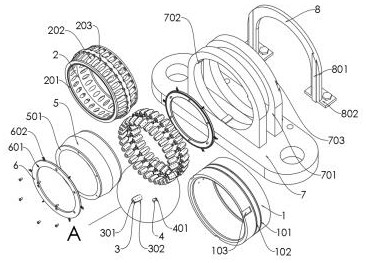

[0028] Example: please refer to Figure 1 to Figure 8 shown:

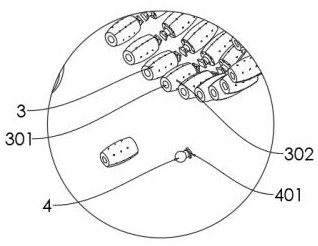

The present invention provides a self-aligning roller bearing based on stirring equipment, including a bearing outer ring 1; the bearing outer ring 1 is installed in a bearing seat 7, a fixing frame 8 is inserted on the right side wall of the bearing seat 7, and the inner part of the bearing outer ring 1 The cage 2 and the bearing inner ring 5 are sleeved. The cage 2 is arranged between the bearing outer ring 1 and the bearing inner ring 5. The cage 2 is rotatably connected with a heat dissipation roller 3, and a side wall of the heat dissipation roller 3 is connected There are ball heads 4, and ferrules 6 are installed on the left and right side walls of the inner ring 5 of the bearing. When in use, the spherical roller bearing has self-aligning performance, so it is not easily affected by shaft bending, and is suitable for installation errors or shaft deflection. When the angle error is caused, in addition to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com