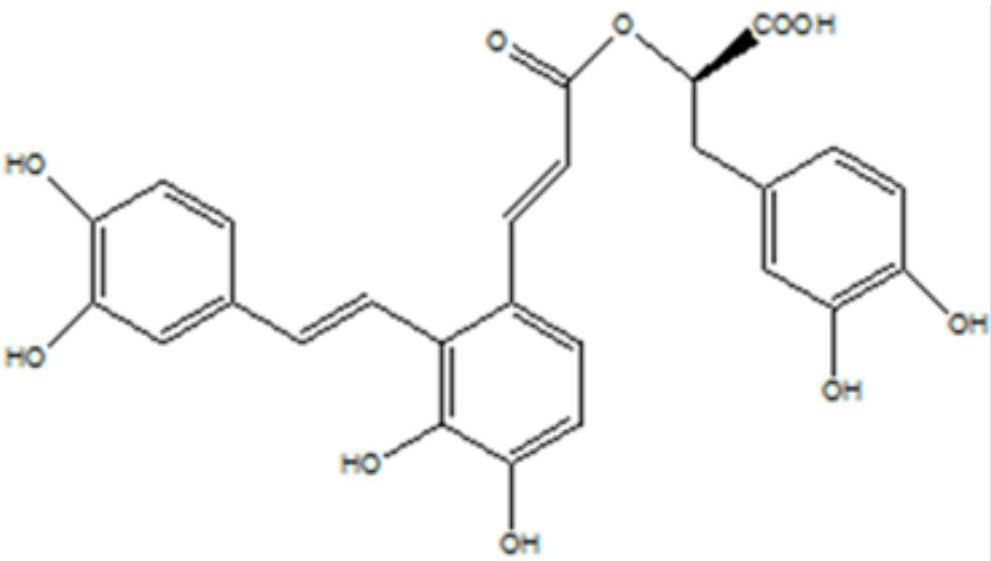

Preparation method of salvianolic acid A

A salvianolic acid, high-content technology, applied in the field of preparation of salvianolic acid A, can solve the problems of increased separation difficulty, complicated use process, high cost, etc., and achieve the goals of shortened separation and purification time, reduced labor intensity, and improved yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

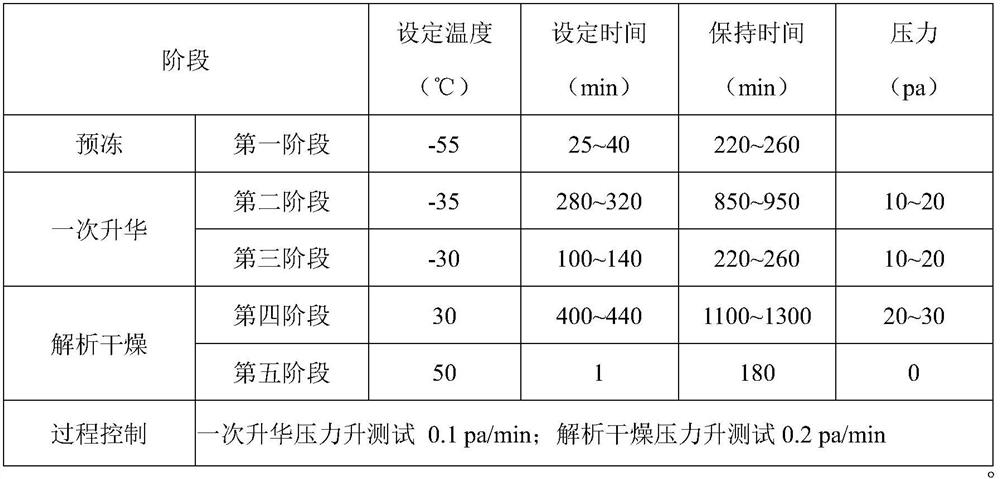

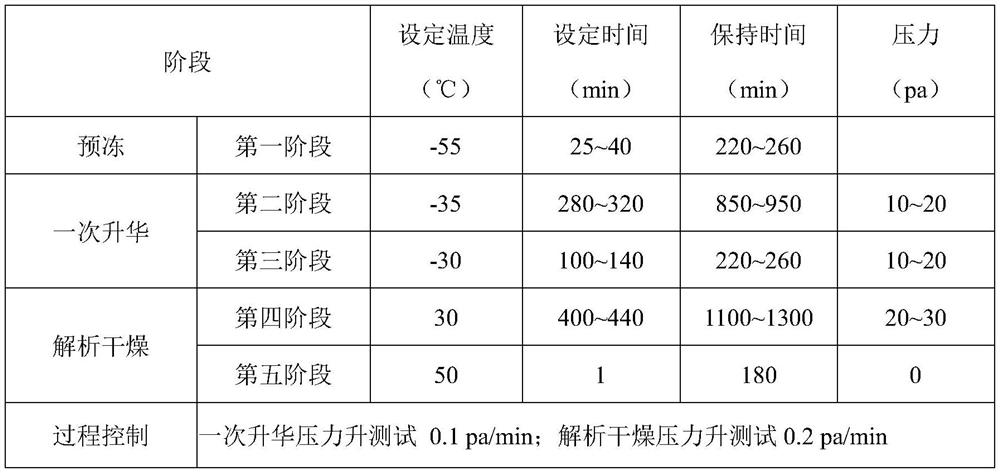

Method used

Image

Examples

Embodiment 1-4

[0056] Example 1-4: Dalicolic acid B water sedimentation

Embodiment 1

[0058] Take salvia herbs (drinking tablets, thick tablets), 4 parts, 100g per part, crushed, through a four-mesh sieve, soaked in water at temperature 78 °C± 2 °C three times (10 times, 8 times, 6 times), each time extracted for 1h. The extract was concentrated at 60 °C under reduced pressure to the relative density of the extract 1.15, combined with the concentrate, added 95% ethanol to adjust the ethanol concentration in the solution of 70%, 25 °C ± 2 °C at a stand alcohol deposition for 36h, filtered, the filtrate was concentrated at T≤65 °C (60 °C) under reduced pressure to the ethanol concentration in the solution ≤5% (4%), to obtain an alcohol deposition concentrate.

Embodiment 2

[0060] Take salvia herbs (short section), 4 parts, 100g per part, crushed, through a four-mesh sieve, soaked in water at temperature 75 °C± 2 °C for three times (10 times, 8 times, 6 times), each time extracted for 1.5h. The extract was concentrated at 50 °C under reduced pressure to the relative density of the extract 1.05, combined with the concentrate, added 90% ethanol to adjust the ethanol concentration in the solution of 75%, 35 °C ± 2 °C at 2 °C let stand for 24h, filtered, the filtrate was concentrated at T≤65 °C (50 °C) under reduced pressure to the ethanol concentration in the solution ≤5% (5%), to obtain an alcohol deposition concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com