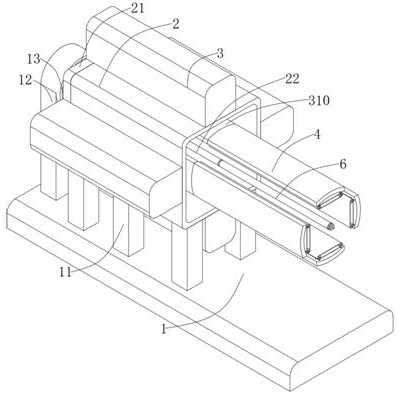

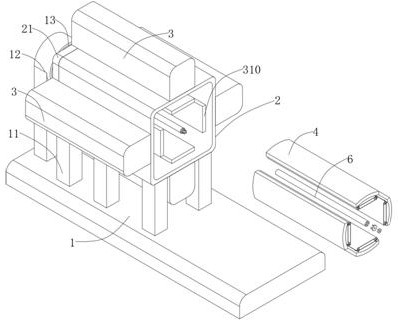

Anti-loosening EPE (Expanded Polyethylene) coiled material winding equipment

A technology of pearl cotton and roll materials, which is applied in the direction of winding strips, packaging recycling, thin material processing, etc., can solve the problems of easy looseness, wrinkles, unfavorable use, etc., and achieve the effect of ensuring the quality of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

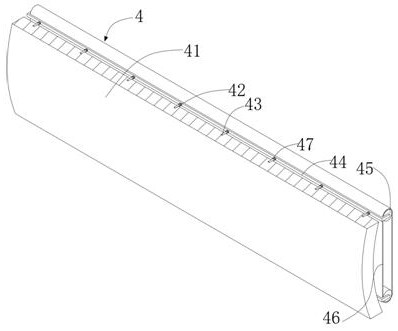

see Figure 4 , the central position of the side plate 21 is fixedly connected to the quill 22 , the quill 22 is located at the inner center of the square shell 2 , and the quill 22 is rotatably connected to the transmission shaft 5 .

[0020] see Figure 4 The end of the transmission shaft 5 is located outside the sleeve shaft 22 and is fixedly connected to the sleeve shaft 51 .

[0021] see Figure 4 , the outer side of one end of the transmission shaft 5 close to the sleeve shaft 51 is fixedly sleeved with the first disc 52, the first disc 52 is fixedly connected to a plurality of first posts 53 on the side close to the winding roller 6, and the winding roller 6 is close to the first disc One end of 52 corresponds to the positions of the plurality of first posts 53 with a plurality of first post slots 61 , the plurality of first posts 53 are inserted into the first post slots 61 , and one end of the sleeve shaft 51 away from the transmission shaft 5 is fixed to the threade...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com