Footwear molding system for direct injection production of footwear

A molding system, technology for footwear, applied in footwear, application, additive manufacturing, etc., can solve the problem of sole material waste, etc., achieve the effect of extensive design, avoid material exudation and trimming operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

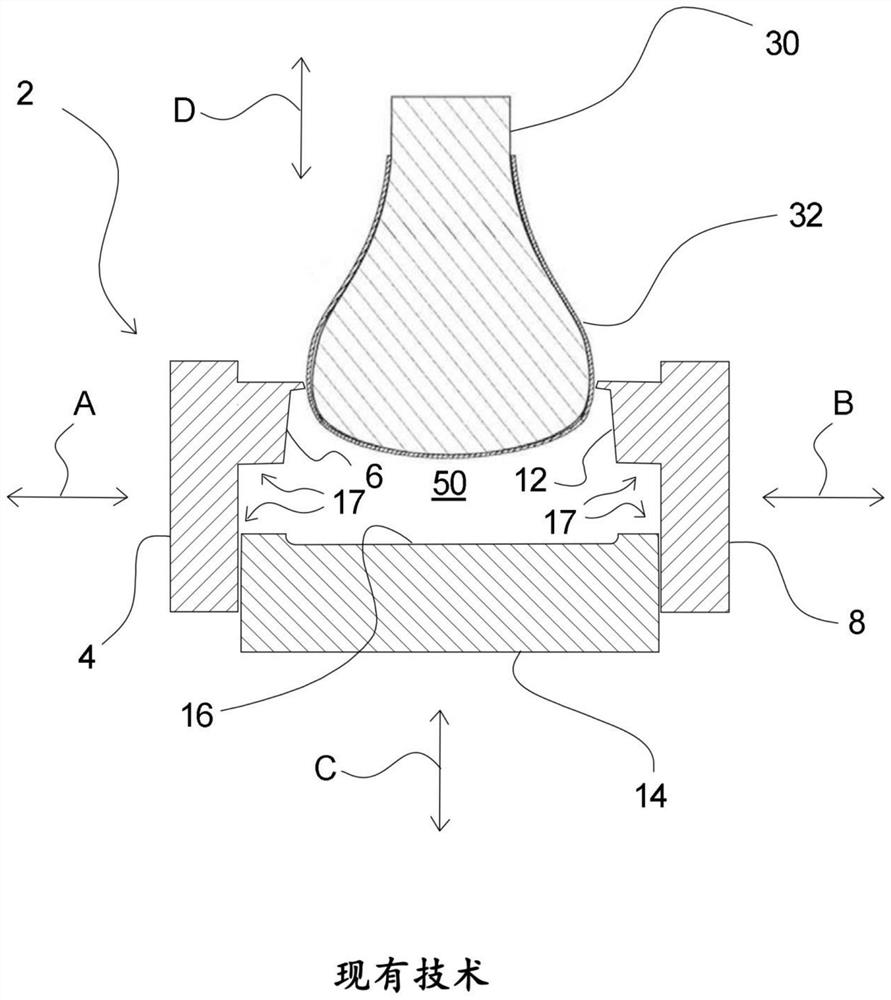

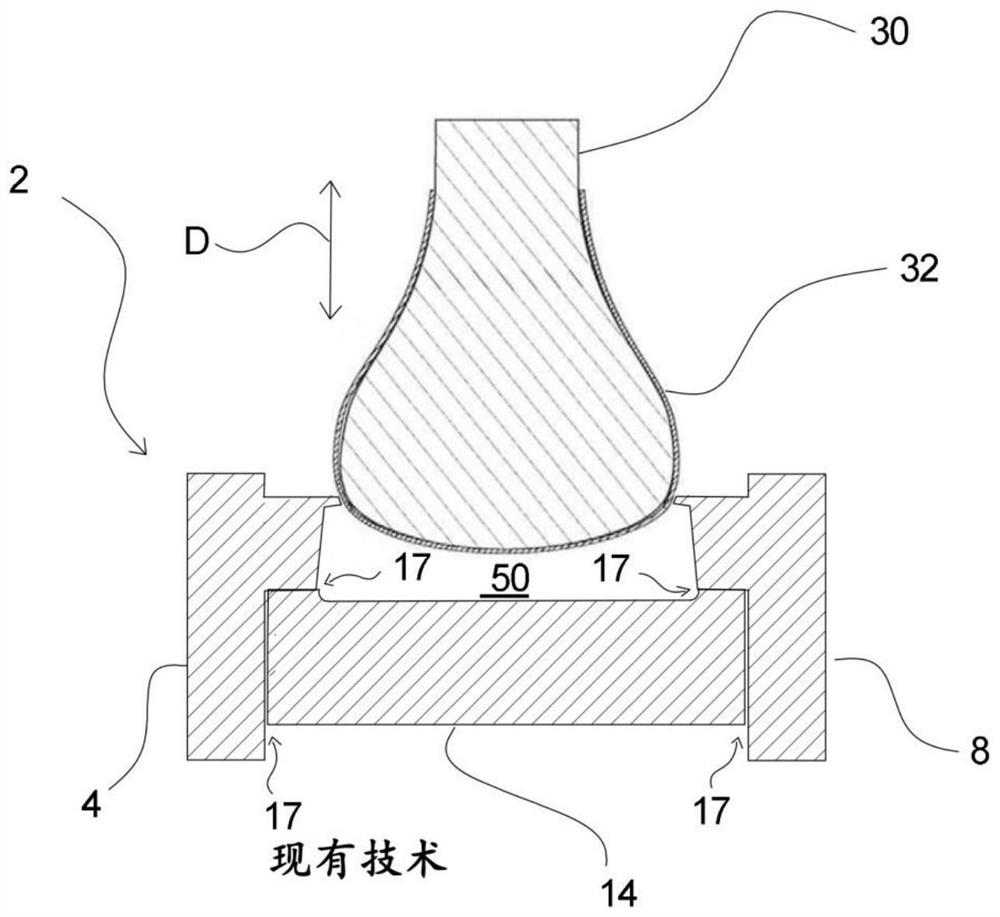

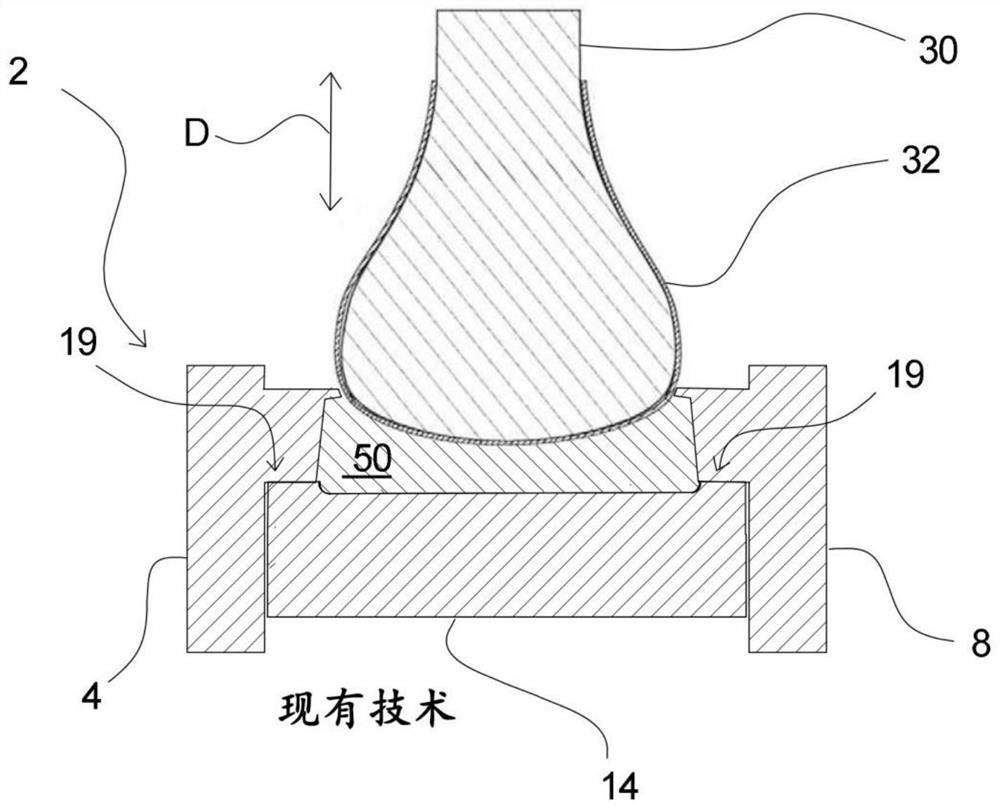

[0096] refer to Figure 1a , Figure 1b and Figure 1c, will illustrate a prior art molding system. These figures schematically show a prior art mold 2 and a last 30, both in cross-sectional view, that can be used for direct injection molding of footwear according to the prior art. The mould 2 may be made of metal (eg aluminium, eg CNC machined), and as Figure 1a and Figure 1b As shown, a first side mold 4, a second side mold 8 and a bottom mold 14 may be included, arranged in such a way that the mold 2 can be opened and closed, for example by the first side mold 4 and the second side mold 8 It is possible to move in the horizontal direction as indicated by arrows A, B, and in the vertical direction as indicated by arrow C by means of the bottom mold 14 being arranged.

[0097] Furthermore, if Figure 1a As shown, upper 32 may be placed on last 30 and may move in various directions with upper 32, including downward relative to mold 2 as indicated by arrow D. FIG. It w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com