Grounding diversion concrete structure

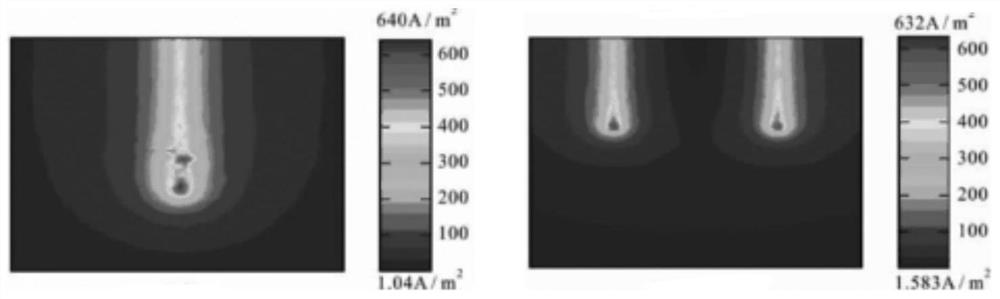

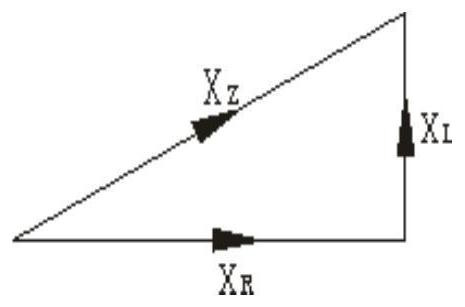

A technology of diversion layer and metal grounding, which is applied in the direction of connection, connection contact materials, and parts of connection devices, etc. It can solve the problems of grounding body corrosion resistance and ground potential hazards, waste of non-ferrous metal resources, and difficulty in reducing resistance. , to achieve the effects of alleviating the hazards of rising ground potential, alleviating the hazards of high ground potential, and increasing the diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1, in the area of 500Ωm<soil resistivity<1500Ωm, the grounding diversion anti-corrosion concrete powder includes the following raw materials by weight: 10 parts of ferrophosphorus powder, 0.5 parts of neodymium oxide, 1.5 parts of hydrophobic powder, and iron ore tailing powder 12 parts, 52 parts of graphite powder, 18 parts of bentonite, 3 parts of calcium carbonate and 3 parts of calcium sulfate;

Embodiment 2

[0065] Example 2, in the drier areas of the northern plateau with soil resistivity >1500Ωm, the grounding diversion anticorrosion concrete powder includes the following raw materials by weight: 11 parts of ferrophosphorus powder, 0.2 parts of neodymium oxide, 1.6 parts of hydrophobic powder, and iron ore tailing powder 13 parts of raw materials, 50 parts of graphite powder, 20 parts of bentonite, 3 parts of calcium carbonate and 3 parts of calcium sulfate;

Embodiment 3

[0066] Example 3: In the humid and rainy areas in the south where the soil resistivity is less than 500Ωm, the grounding diversion anticorrosion concrete powder includes the following raw materials by weight: 9 parts of ferrophosphorus powder, 0.6 parts of neodymium oxide, 1.4 parts of hydrophobic powder, and iron ore tailing powder 13 parts of raw materials, 52 parts of graphite powder, 18 parts of bentonite, 2 parts of calcium carbonate and 4 parts of calcium sulfate.

[0067] Further, the diversion anti-corrosion concrete belt 2 is preferably mixed by 70%-80% of the ground diversion anti-corrosion concrete powder and 20%-30% of the cementitious material by weight percentage;

[0068] For different soil resistivities, the proportion of components in the diversion and anti-corrosion concrete belt 2 has the following examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com