Mobile terminal data acquisition and processing method in flexible production dispatching and multi-reporting mode

A flexible production and mobile terminal technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as uneven staffing, reduced production reporting experience and efficiency, and low informatization level that cannot be implemented, so as to reduce work tasks, reduce reporting time, and improve the efficiency of reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

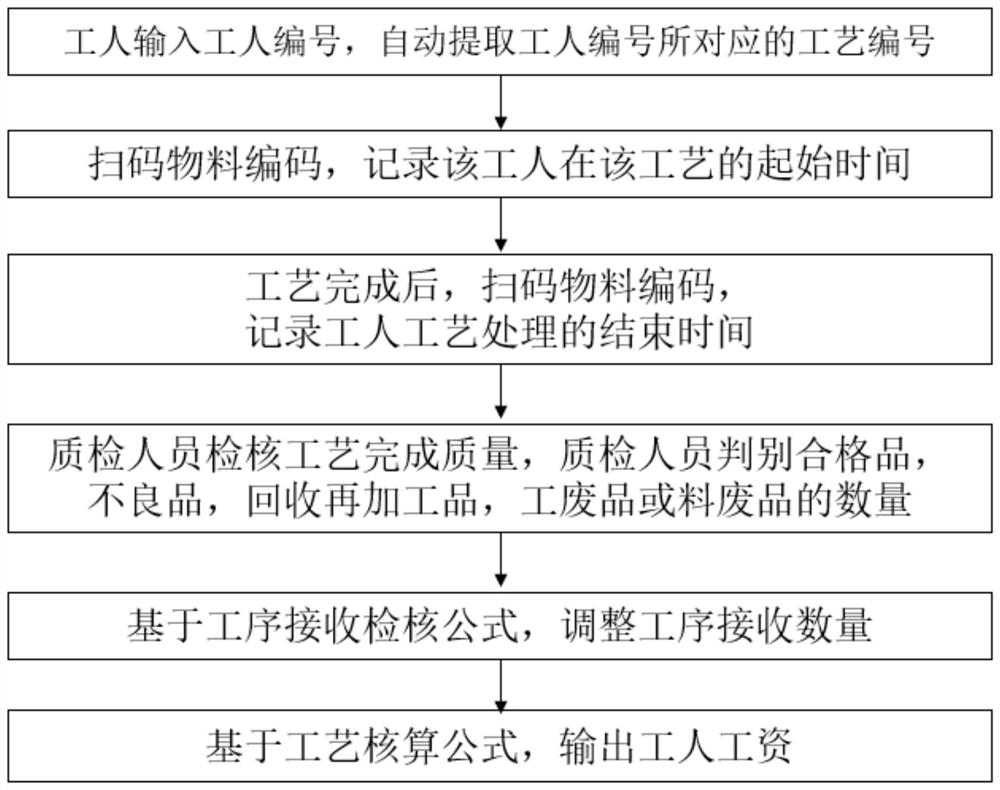

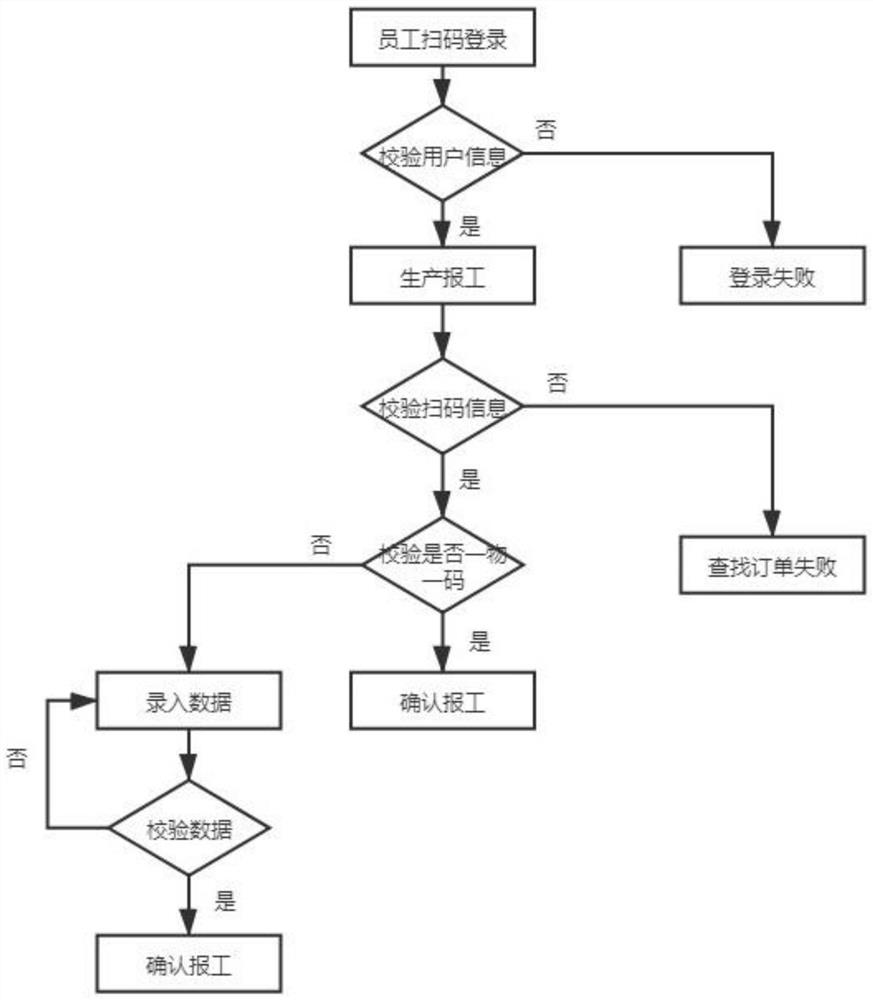

[0038] like figure 1 As shown, a mobile terminal data collection and processing method in flexible production dispatching and multi-reporting mode includes the following steps:

[0039] Step 1: The worker enters the worker number, and automatically extracts the process number corresponding to the worker number;

[0040] Step 2: Scan the material code to record the starting time of the worker in the process, and at the same time determine whether the material belongs to the finishing part mode or batch part mode based on the material code,

[0041] Step 3: After the process is completed, scan the material code and record the end time of the worker's process;

[0042] Step 4: The quality inspector checks the quality of the completed process, and the quality inspector judges the quantity of qualified products, defective products, recycled and reprocessed products, industrial waste products or material waste products;

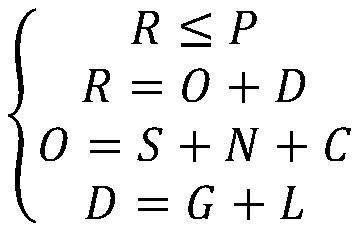

[0043] Step 5: Based on the process receipt check formula, ...

Embodiment 2

[0058] The difference between Embodiment 2 and Embodiment 1 is that the rules for material numbering are set, which facilitates direct reading of data.

[0059] A mobile terminal data collection and processing method in flexible production dispatch and multi-report mode, comprising the following steps:

[0060] Step 1: The worker enters the worker number, and automatically extracts the process number corresponding to the worker number;

[0061] Step 2: Scan the material code to record the starting time of the worker in the process, and at the same time determine whether the material belongs to the finishing part mode or batch part mode based on the material code,

[0062] Step 3: After the process is completed, scan the material code and record the end time of the worker's process;

[0063] Step 4: The quality inspector checks the quality of the completed process, and the quality inspector judges the quantity of qualified products, defective products, recycled and reprocessed...

Embodiment 3

[0068] The difference between Embodiment 3 and Embodiment 1 is that in the batch mode, the operator needs to manually enter the number of materials.

[0069] A mobile terminal data collection and processing method in flexible production dispatch and multi-report mode, comprising the following steps:

[0070] Step 1: The worker enters the worker number, and automatically extracts the process number corresponding to the worker number;

[0071] Step 2: Scan the material code. When the material code determines that the material belongs to the finishing part mode, directly record the starting time of the worker in the process; when the material code determines that the material belongs to the batch part mode, enter the quantity of the material code manually.

[0072] Step 3: After the process is completed, scan the material code and record the end time of the worker's process;

[0073] Step 4: The quality inspector checks the quality of the completed process, and the quality inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com