Water supply pipe buttress with functions of height adjustment, shock absorption and electrochemical corrosion in pipe gallery

An electrochemical and water supply pipe technology, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, pipe components, etc., can solve the problems of pipe disengagement, pipe water flow sloshing, pipe stress unevenness, etc., to achieve uniform stress and reduce stress. The effect of small force unevenness and isolation of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

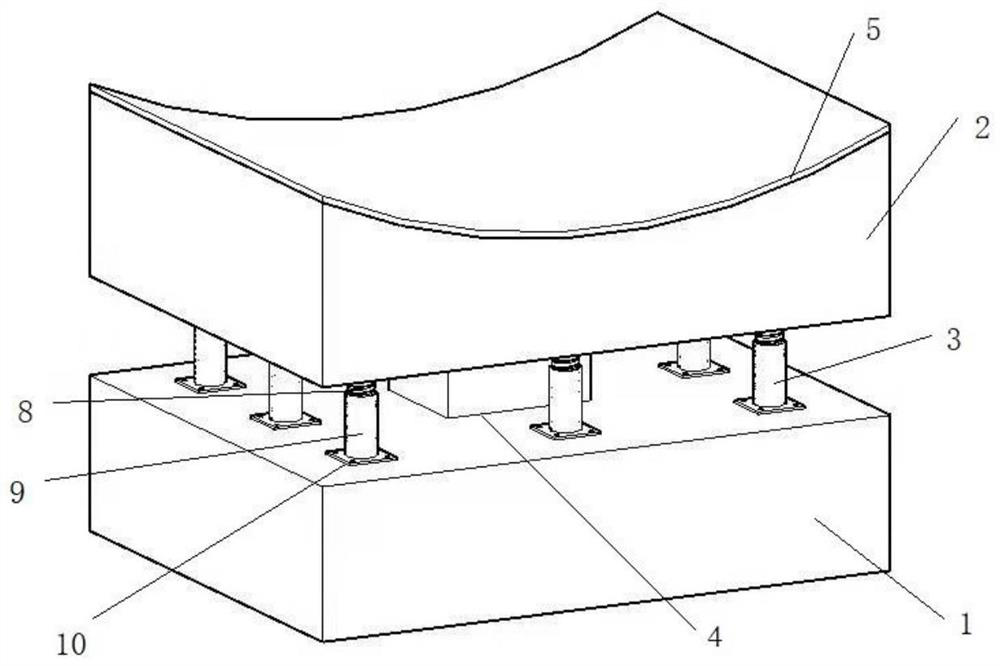

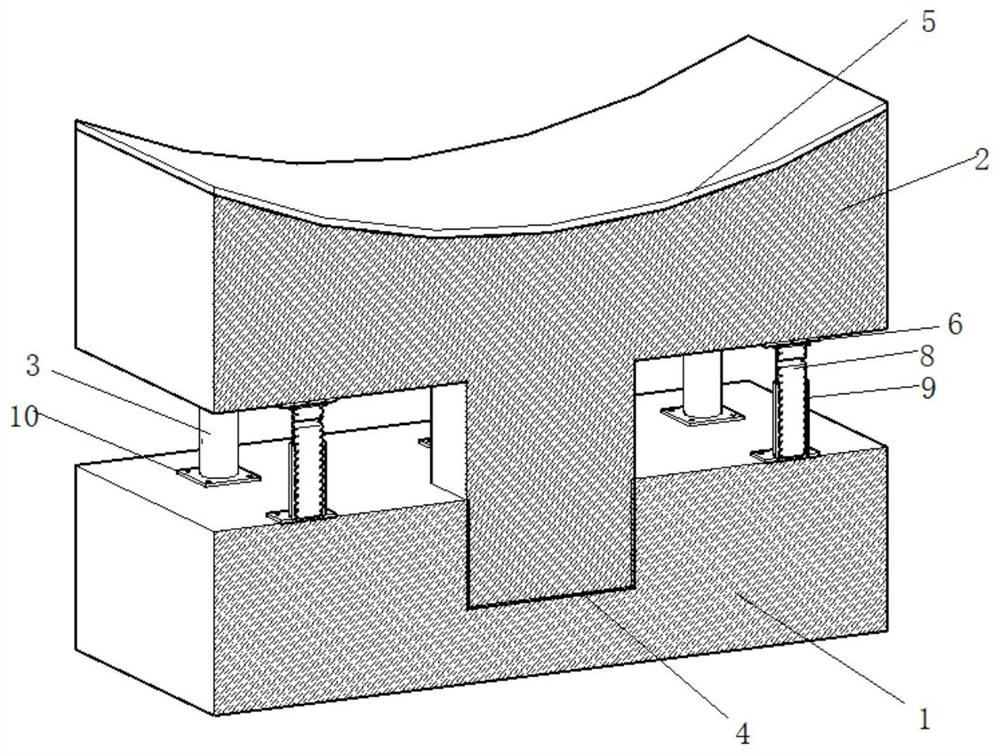

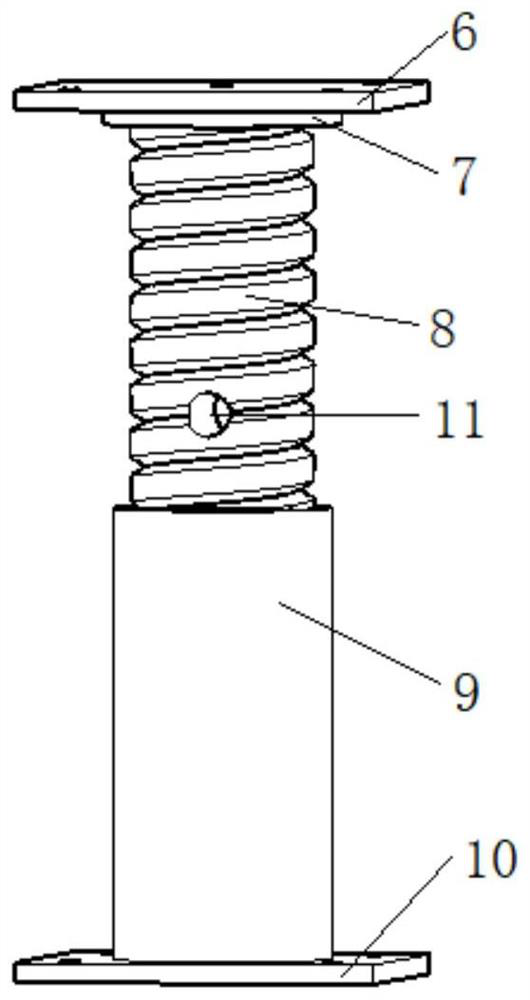

[0032] The present invention is a kind of water supply pipe support pier with height adjustment, shock absorption and electrochemical corrosion in the pipe gallery, such as figure 1 and 2 As shown, including the lower pier block 1, the upper pier block 2 and a plurality of height-adjusting supports 3 arranged in the pipe gallery, the lower pier block 1 and the upper pier block 2 can adopt reinforced concrete cast-in-situ structures, or Prefabricated or steel structures may be used, where:

[0033] The lower block 1 of the buttress is a horizontally arranged cuboid support body, and the bottom is fixed on the corridor body of the pipe gallery; the upper block 2 of the buttress is a horizontally arranged block, located above the lower block 1 of the buttress, And the distance between it and the lower block 1 of the buttress is adjustable; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com