Preparation method of early-strength dispersing type water reducing agent and concrete prefabricated part of early-strength dispersing type water reducing agent

A manufacturing method and decentralized technology, applied in the field of building materials, can solve the problems of concrete dispersion and rapid loss of fluidity, high energy consumption of thermal curing methods, slow development of early strength, etc., to increase steric hindrance effect and improve flow performance, faster conversions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

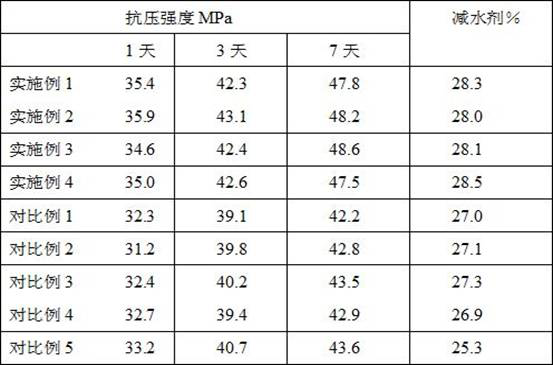

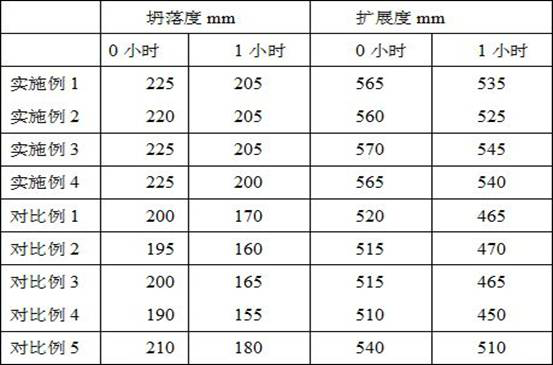

Examples

Embodiment 1

[0028] A concrete prefabricated part added with an early-strength dispersing water-reducing agent and a manufacturing method thereof, characterized in that it comprises the following steps

[0029] (1) Preparation of dispersing monomer: in parts by weight, add 12 parts by weight of maleic anhydride, 35 parts of 4-hydroxyphenylboronic acid pinacol ester and 100 parts of acetone into the autoclave to mix and then add 2 parts of toluenesulfonic acid. parts and 1.5 parts of methyl hydroquinone, the temperature was raised to 110 ° C, and pressurized to 0.25 MPa, the pressure was maintained for 120 minutes, and after the pressure was released and cooled, the dispersed monomer was obtained;

[0030] (2) Add ethylene glycol monovinyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, methacrylic acid, sodium sulfite and deionized water into the reaction kettle, stir evenly and drop into step (1) ) obtained dispersing monomer, the dropping rate is 5 ml / min, the molar rat...

Embodiment 2

[0035] A concrete prefabricated part added with an early-strength dispersing water-reducing agent and a manufacturing method thereof, characterized in that it comprises the following steps

[0036](1) Preparation of dispersing monomer: in parts by weight, add 15 parts by weight of maleic anhydride, 40 parts of 4-hydroxyphenylboronic acid pinacol ester and 100 parts of acetone into the autoclave to mix and then add 1.5 parts of toluenesulfonic acid. 1.5 parts of methyl hydroquinone and 1.5 parts of methyl hydroquinone, the temperature was raised to 110 ° C, and pressurized to 0.3 MPa, the pressure was maintained for 90 minutes, and after the pressure was released and cooled, the dispersed monomer was obtained;

[0037] (2) Add ethylene glycol monovinyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, methacrylic acid, sodium sulfite and deionized water into the reaction kettle, stir evenly and drop into step (1) ), the dropping rate is 7 ml / min, and the molar r...

Embodiment 3

[0042] A concrete prefabricated part added with an early-strength dispersing water-reducing agent and a manufacturing method thereof, characterized in that it comprises the following steps

[0043] (1) Preparation of dispersing monomer: by weight, add 10 parts by weight of maleic anhydride, 40 parts of 4-hydroxyphenylboronic acid pinacol ester and 100 parts of acetone into the autoclave and mix and then add 2 toluenesulfonic acid. parts and 1.5 parts of methyl hydroquinone, the temperature was raised to 100 ° C, and pressurized to 0.3 MPa, the pressure was maintained for 60 minutes, and after the pressure was released and cooled, the dispersed monomer was obtained;

[0044] (2) Add ethylene glycol monovinyl polyoxyethylene ether, 2-acrylamide-2-methylpropanesulfonic acid, methacrylic acid, sodium sulfite and deionized water into the reaction kettle, stir evenly and drop into step (1) ), the dropping rate is 8 ml / min, and the molar ratio of ethylene glycol monovinyl polyoxyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com