High numerical control bending device for steel pipe furniture and bending method of high numerical control bending device

A bending device and furniture technology, which is applied in storage devices, feeding devices, positioning devices, etc., can solve the problems of control, low steel pipe replacement efficiency, inconvenient steel pipe bending angle, etc., and achieve high replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

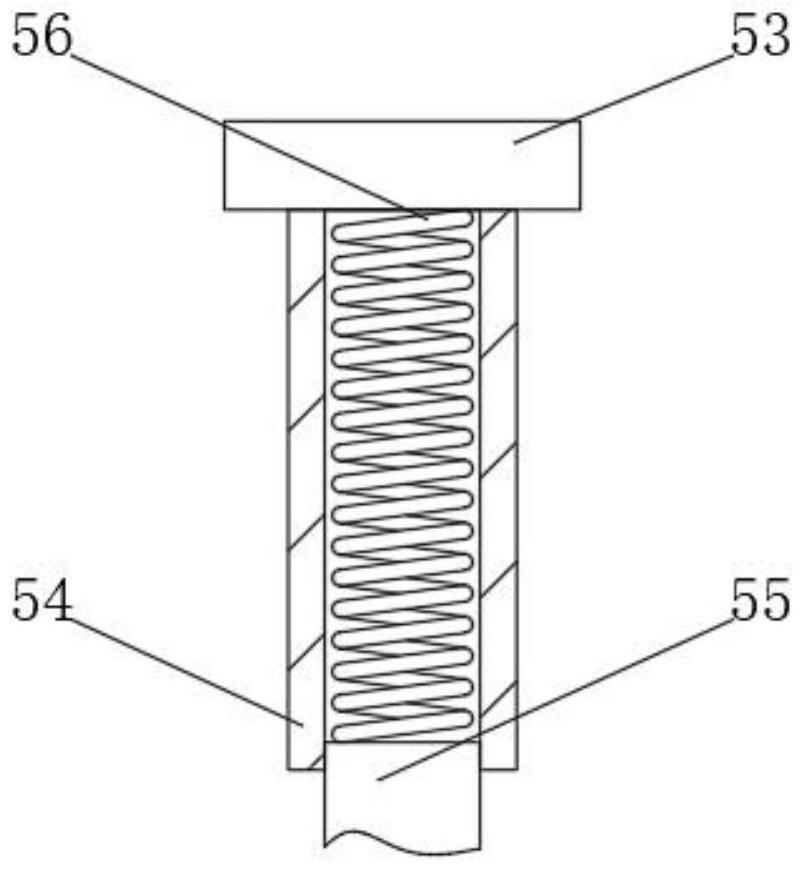

[0035] Wherein, one end of the compression spring 67 is in contact with the frame 1, and the other end of the compression spring 67 is in contact with the support rod 66. Pass

[0037] Wherein, the screw 92 is welded with a turntable 93, and the turntable 93 is in contact with the hanger plate 91. By setting the dial 93,

[0038] Wherein, a guide rod 99 is welded on the support 97, and the guide rod 99 and the hanging plate 91 are slidably connected. By setting the guide rod

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com