Preparation method of anti-dandruff shampoo

A shampoo and deionized water technology, applied in the field of daily chemicals, can solve the problems of weakened scalp functional barrier, complicated preparation process, difficult sedimentation and separation, etc., and achieve the effect of superior wetting and combability, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

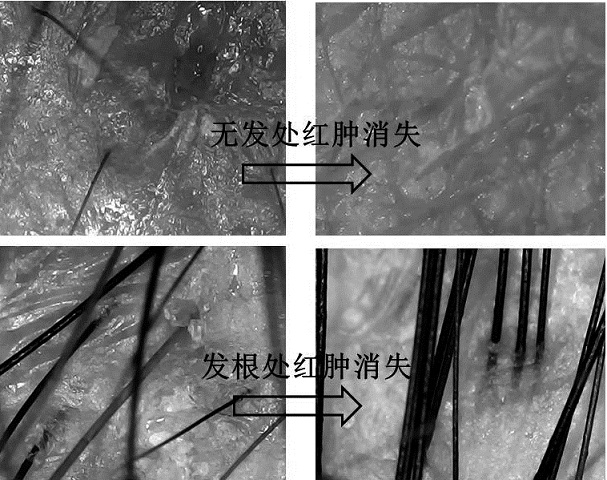

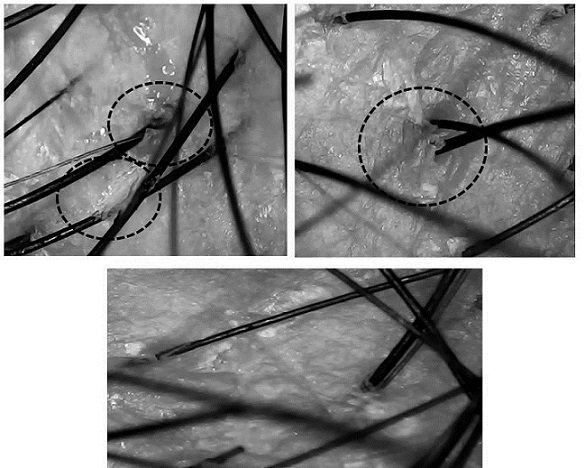

Image

Examples

Embodiment 1

[0051] A preparation method of anti-dandruff shampoo, comprising the steps of:

[0052] (1) Alkylphenol ether sulfosuccinate sodium salt and sodium lauryl ether sulfate anionic surfactant were dissolved in nano-selenium sulfide / porous micron carbon sphere deionized water at a mass ratio of 1: (0.8), The dissolution temperature was 70° C., the stirring speed was 100 rpm, and the stirring time was 4 hours to obtain solution A.

[0053] (2) Mix polyquaternium-7 and guar hydroxypropyltrimethylammonium chloride in deionized water according to the mass ratio (1.7): 1, the dissolution temperature is 50°C, the stirring speed is 100rpm, and the stirring time is 0.5h , to obtain solution B.

[0054] (3) Cool the solution A obtained in step (1) to 50°C, then add solution B, stir well, then add citric acid pH regulator, carboxymethylcellulose sodium thickener, citronellol fragrance, caprylic acid / Capric triglyceride care agent, cetyl alcohol emulsification stabilizer, monoglyceride em...

Embodiment 2

[0075] A preparation method of anti-dandruff shampoo, comprising the steps of:

[0076] (1) Alkylphenol ether sulfosuccinate sodium salt and sodium lauryl ether sulfate anionic surfactant were dissolved in nano-selenium sulfide / porous micron carbon sphere deionized water at a mass ratio of 1: (0.95), The dissolution temperature was 72.5° C., the stirring speed was 150 rpm, and the stirring time was 4.5 hours to obtain solution A.

[0077] (2) Mix polyquaternium-7 and guar hydroxypropyltrimethylammonium chloride in deionized water according to the mass ratio (1.95): 1, the dissolution temperature is 55°C, the stirring speed is 150rpm, and the stirring time is 0.75h , to obtain solution B.

[0078] (3) Cool down solution A obtained in step (1) to 55°C, then add solution B, stir evenly, then add citric acid pH regulator, carboxymethylcellulose sodium thickener, citronellol fragrance, caprylic acid / Capric triglyceride care agent, cetyl alcohol emulsification stabilizer, monogl...

Embodiment 3

[0099] A preparation method of anti-dandruff shampoo, comprising the steps of:

[0100] (1) Alkylphenol ether sulfosuccinate sodium salt and sodium lauryl ether sulfate anionic surfactant were dissolved in nano-selenium sulfide / porous micron carbon sphere deionized water at a mass ratio of 1: (1.1), The dissolution temperature was 75° C., the stirring speed was 200 rpm, and the stirring time was 5 h to obtain solution A.

[0101] (2) Mix polyquaternium-7 and guar hydroxypropyltrimethylammonium chloride in deionized water according to the mass ratio (2.2): 1, the dissolution temperature is 60°C, the stirring speed is 200rpm, and the stirring time is 1h. Solution B is obtained.

[0102] (3) Cool down solution A obtained in step (1) to 60°C, then add solution B, stir evenly, then add citric acid pH regulator, carboxymethylcellulose sodium thickener, citronellol fragrance, caprylic acid / Capric triglyceride care agent, cetyl alcohol emulsification stabilizer, monoglyceride emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com