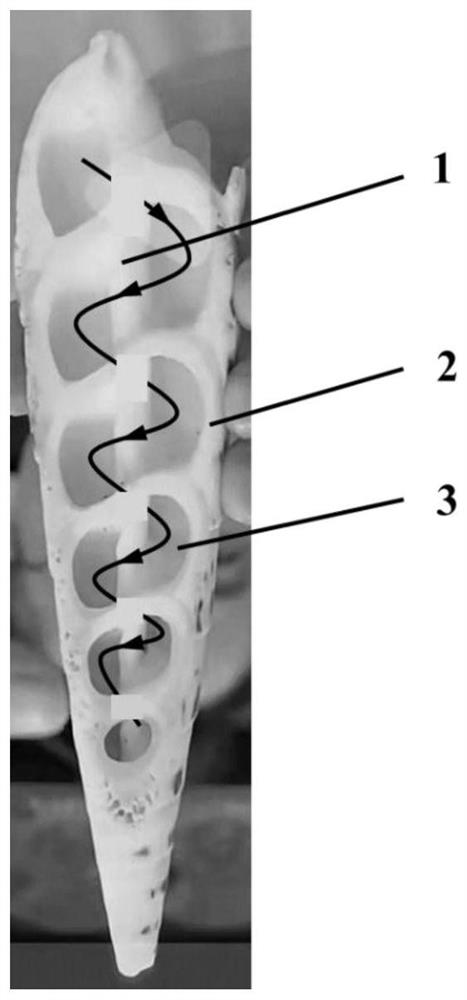

Bamboo shoot spiral imitating bidirectional low-frequency sound absorption metamaterial and additive manufacturing method thereof

A metamaterial and sound absorption technology, applied in the field of acoustic metamaterials, to achieve high strength and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

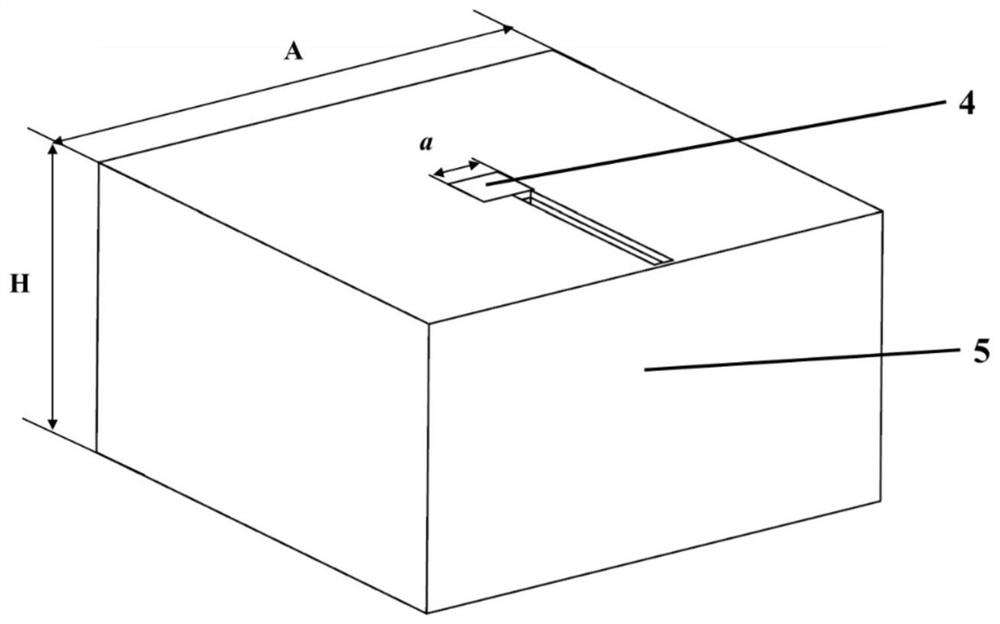

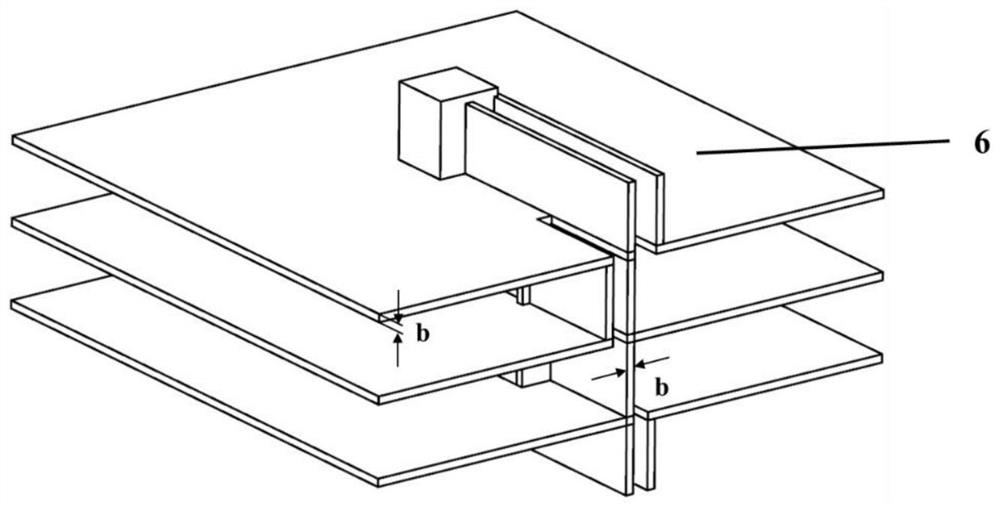

Embodiment 1

[0042] When designing the structure of the bidirectional low-frequency sound-absorbing metamaterial like bamboo shoots and snails, it is necessary to first determine the target sound-absorbing frequency range, then select the appropriate material according to the bearing requirements, and constantly modify the size parameters to achieve the set goal. The following are the manufacturing steps. :

[0043] (1) Set the sound absorption frequency band: Set the target sound absorption frequency to be about 245Hz, which belongs to the low frequency noise frequency band and is difficult to be absorbed by traditional sound absorption materials.

[0044] (2) Optimization of sound absorption performance: The designed structural model was constructed using COMSOL, and the side length of the unit cell section was preset as 50mm, and the remaining parameters took any value within the constraints to simulate and calculate the sound absorption effect. If the set sound absorption effect is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com