High-performance wrought aluminum alloy and manufacturing method

A technology for deforming aluminum alloy and manufacturing method, applied in the field of aluminum alloy, can solve problems such as reducing cost, and achieve the effects of reducing production cost, eliminating anisotropy of mechanical properties, and excellent super strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

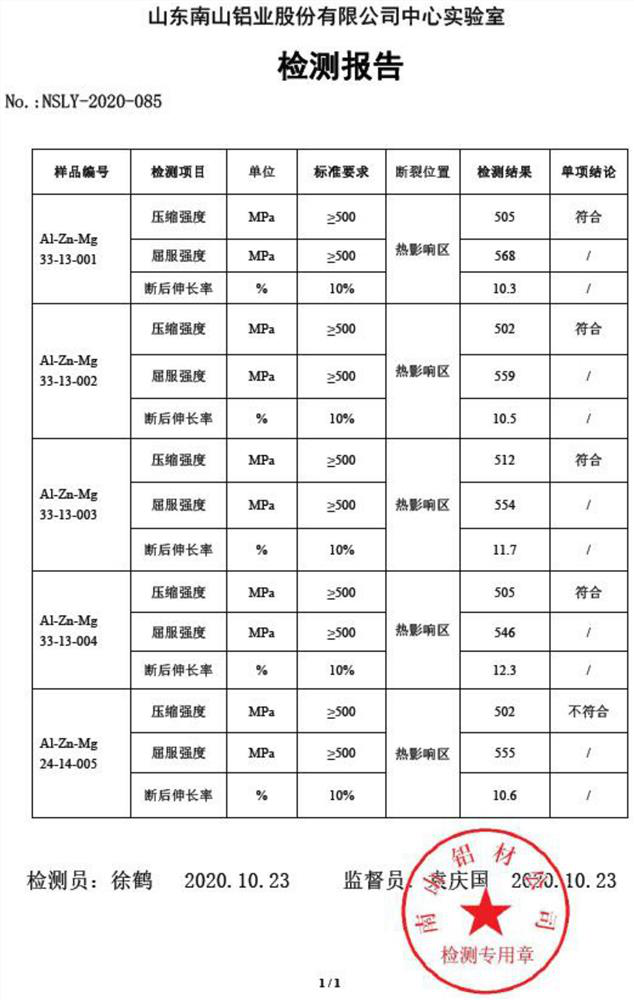

Embodiment 1

[0053] Put pure aluminum, pure zinc and pure magnesium into a vacuum induction melting furnace, melt at 755 °C under the protection of high-purity argon and keep for 30 minutes, and then add Al-20Ag master alloy, Al-25Sc master alloy and Al-25Zr intermediate The alloy was kept for 2h, and finally cooled to 690°C, left standing for 15min, and poured. In this way, the composition is 6.0wt.%Zn, 3.0wt.%Mg, 1.6wt.%Ag, 0.45wt.%Sc, 0.7wt.%Zr, the total amount of impurity elements is less than 0.02wt.% and the balance is Al, The aluminum alloy round ingot with the size of Φ110mm×85mm (the size after removing the riser) is then homogenized at 575℃×24h in an argon protective atmosphere to uniform the structure and eliminate the segregation and solid solution intergranular phase.

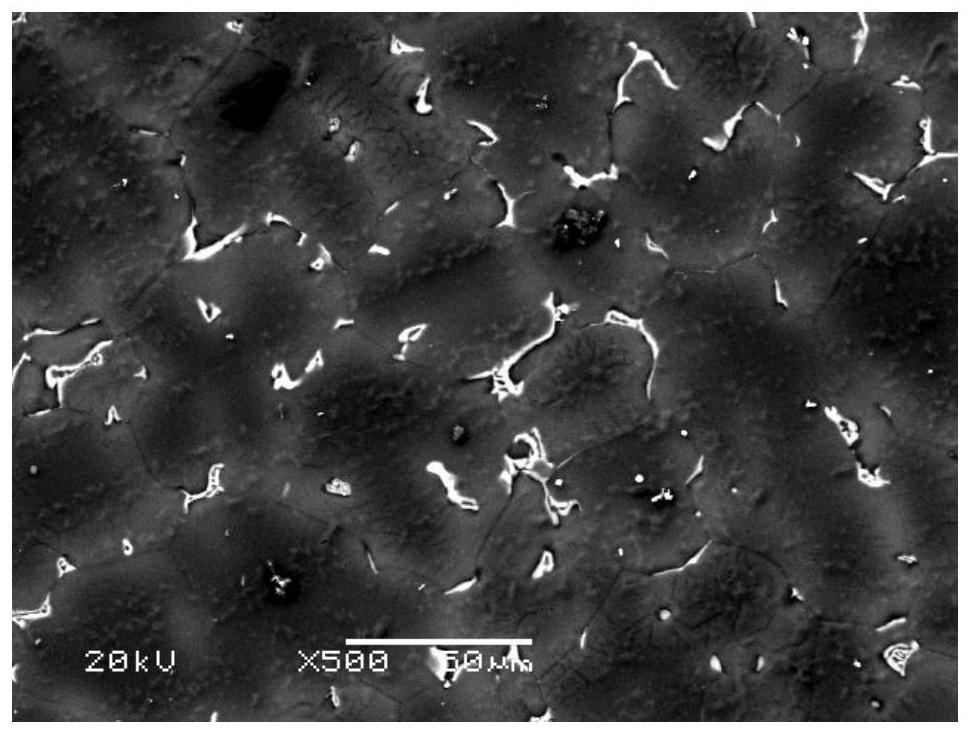

[0054] The oxide scale on the surface of the round ingot was removed by turning, and cut into extruded specimens of Φ100mm×80mm. After preheating at 250°C for 0.5h, it was extruded into an aluminum alloy bar o...

Embodiment 2

[0057] Put pure aluminum, pure zinc and pure magnesium into a vacuum induction melting furnace, melt at 720℃ under the protection of high-purity argon and keep for 25min, then add Al-20Ag master alloy, Al-25Sc master alloy and Al-25Zr intermediate The alloy was kept for 0.5h, and finally cooled to 660°C, left standing for 10min, and poured. In this way, the composition is 7.5wt.%Zn, 3.5wt.%Mg, 2.5wt.%Ag, 0.6wt.%Sc, 0.8wt.%Zr, the total amount of impurity elements is less than 0.02wt.% and the balance is Al, The aluminum alloy round ingot with the size of Φ110mm×85mm (the size after removing the riser); then homogenized at 410℃×24h in an argon protective atmosphere to uniform the structure and eliminate the segregation and solid solution intergranular phase.

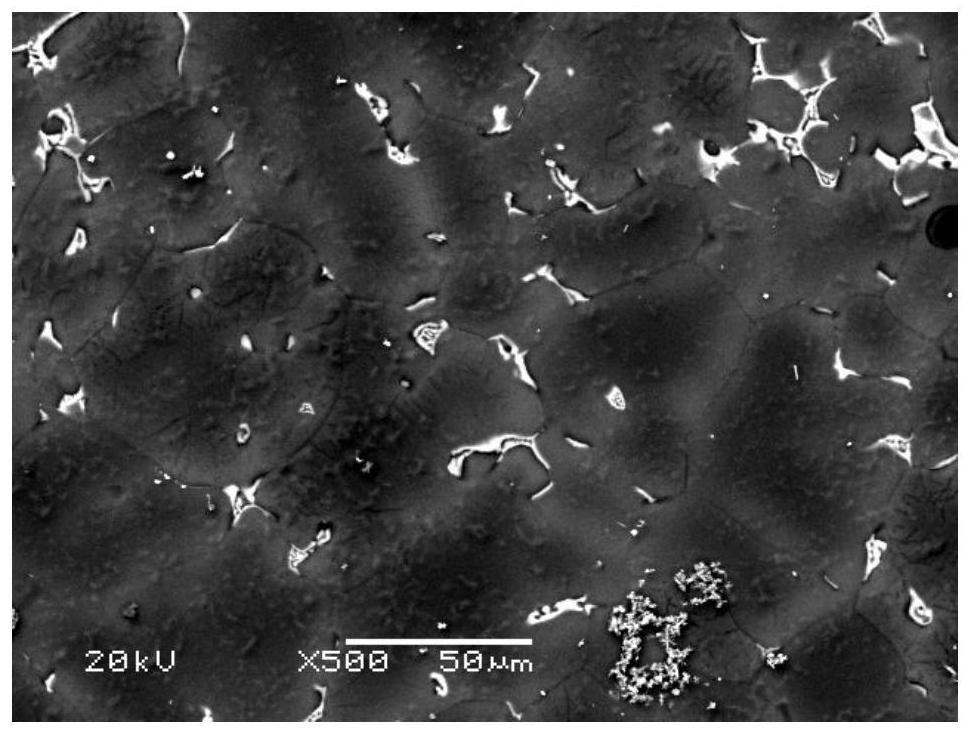

[0058] The oxide skin on the surface of the round ingot was removed by turning, and cut into extruded specimens of Φ100mm×80mm. After preheating at 300 °C for 0.5h, it was extruded into an aluminum alloy bar of Φ30mm at o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com