Nitrogen fertilizer synergist, preparation method and application

A technology of nitrogen fertilizer synergist and fertilizer, which is applied in application, nitrogen fertilizer, fertilization equipment, etc., can solve the problems of low nitrogen fertilizer utilization efficiency, achieve the effects of simple manufacturing process, convenient use, and reduced nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

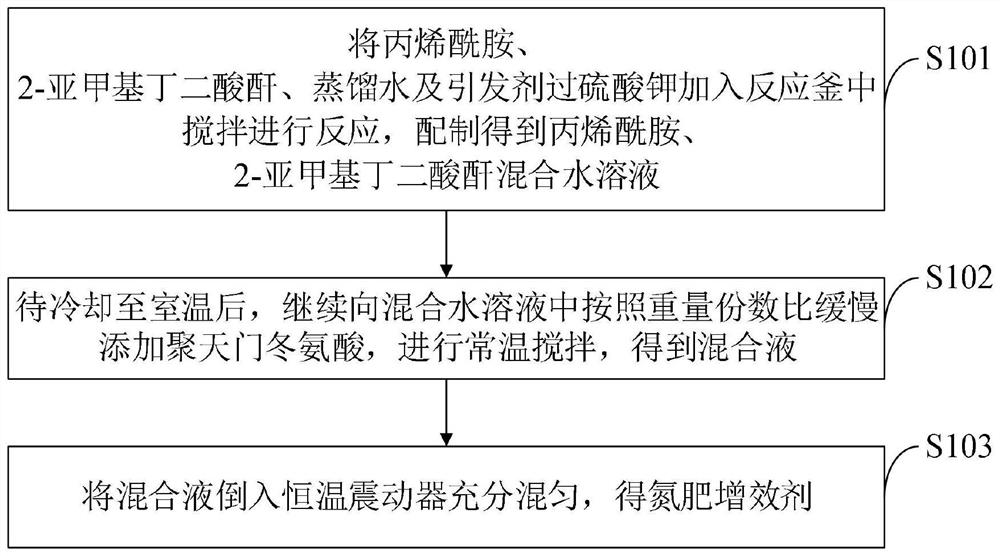

[0046] like figure 1 As shown, the preparation method of the nitrogen fertilizer synergist provided by the embodiment of the present invention comprises the following steps:

[0047] S101, adding acrylamide, 2-methylenesuccinic anhydride, distilled water and an initiator potassium persulfate to the reaction kettle and stirring to react, and preparing a mixed aqueous solution of acrylamide and 2-methylenesuccinic anhydride;

[0048] S102, after being cooled to room temperature, continue to slowly add polyaspartic acid to the mixed aqueous solution according to the ratio of parts by weight, and stir at room temperature to obtain a mixed solution;

[0049] S103, pouring the mixed solution into a constant temperature vibrator and fully mixing to obtain a nitrogen fertilizer synergist.

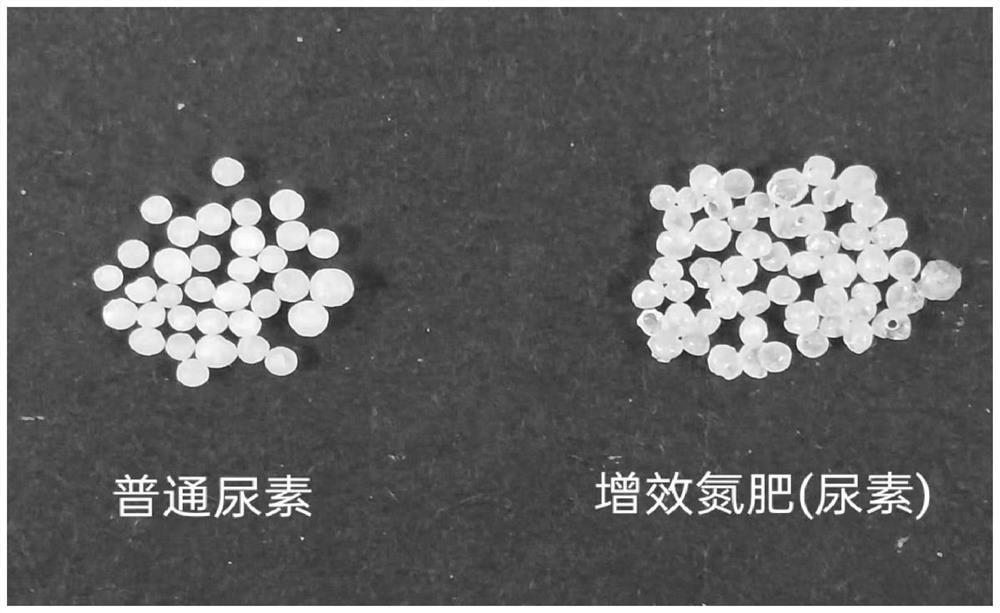

[0050] The nitrogen fertilizer synergist prepared by the present invention can be used for production by spraying on the surface of urea and air-drying. figure 2 It is a comparison diagram of th...

Embodiment 1

[0053] Each component of the raw material of the nitrogen fertilizer synergist provided in the embodiment of the present invention is composed of the following components by weight:

[0054] 8-10 parts of polyaspartic acid, 12-15 parts of 2-methylenesuccinic anhydride, 6-7.5 parts of acrylamide, 0.2-0.6 parts of potassium persulfate, and 800-1200 parts of distilled water.

[0055] The preparation method of the nitrogen fertilizer synergist provided in the embodiment of the present invention is as follows:

[0056] Acrylamide, 2-methylenesuccinic anhydride, distilled water and initiator potassium persulfate are added to the reaction kettle in a proportion of 1:2:80:0.1 by weight, and the temperature is controlled at 30-80°C, and the reaction is performed for 15- In 20 minutes, a mixed aqueous solution of acrylamide and 2-methylenesuccinic anhydride was prepared. After cooling to room temperature, polyaspartic acid was slowly added according to the weight ratio of acrylamide to...

Embodiment 2

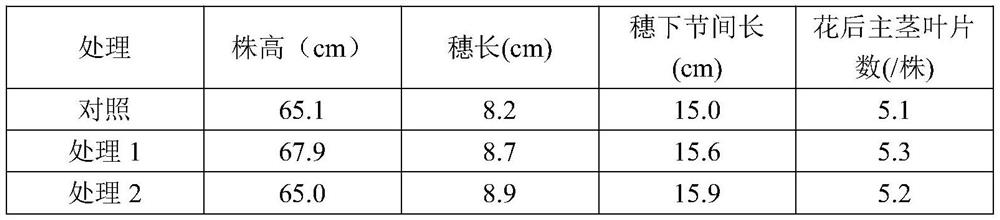

[0072] The nitrogen fertilizer synergist prepared according to the raw materials of Example 1 was sprayed on the surface of the fertilizer to obtain a synergistic compound fertilizer, which was used for the corn growth and development test, and the tested variety was Qiule 218. Two treatments were set up in the experiment, namely control treatment (CK): compound fertilizer (nitrogen: phosphorus: potassium = 20: 15: 10) 50kg / 667m 2 , without synergist; treatment (T1): synergistic compound fertilizer (nitrogen: phosphorus: potassium = 20: 15: 10) 50kg / 667m 2 . Corn was sown in mid-to-late June, with 4,800 plants per acre, with a large row spacing of 80cm, a small row spacing of 50cm, and a plant spacing of 18cm. The experiment adopts an incomplete randomized block design, and each treatment area is 0.8*130=114m 2 , and each treatment was repeated 3 times. In addition, all fertilizers are used as base fertilizer for one-time fertilization, and no top-dressing operation is perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com