Separation system and separation method for flotation decarburization of gasified slag

A sorting system and technology of gasification slag, applied in the direction of solid separation, etc., can solve the problems of high chemical consumption and low efficiency of carbon ash separation, and achieve the effects of low cost, strong adaptability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

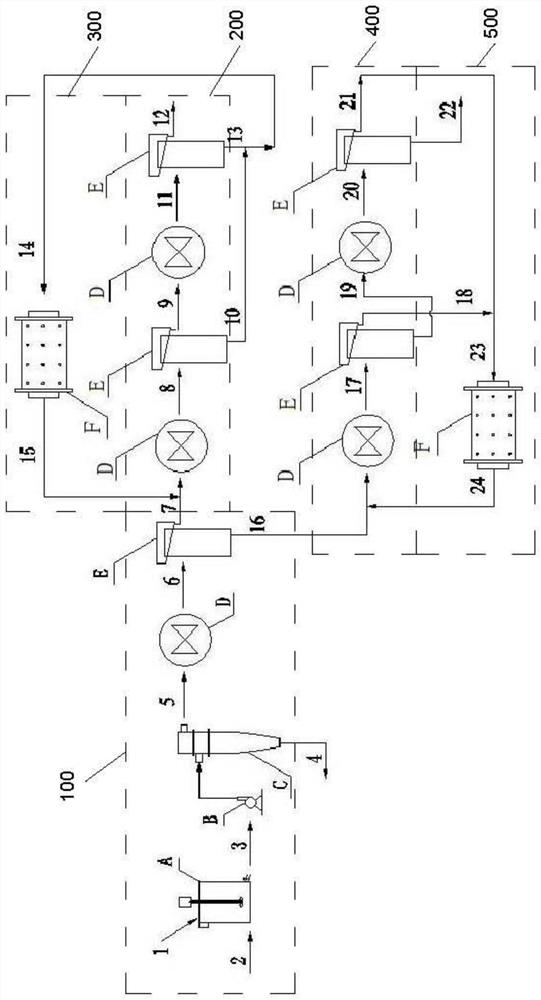

[0033] like figure 1 As shown, the present invention provides a sorting system for flotation decarbonization of gasification slag, including a main feeding circuit 100, a selection branch 200, a selection return branch 300, a sweeping branch 400 and a sweeping return Bypass 500, where:

[0034] The main feeding path 100 includes a mixing drum A, a feeding pump B, a cyclone classification screen C, a set of pulp conditioner D and a set of flotation columns E, which are sequentially connected along the material transmission direction. The top output end of the flotation column E in the circuit 100 is connected to the input end of the beneficiation branch 200, and the bottom output end of the flotation column E in the main feeding circuit 100 is connected to the sweeping the input end of the branch 400;

[0035]The beneficiation branch 200 includes at least two sets of beneficiation units connected in series in multiple stages, and each set of the beneficiation units includes a...

Embodiment 2

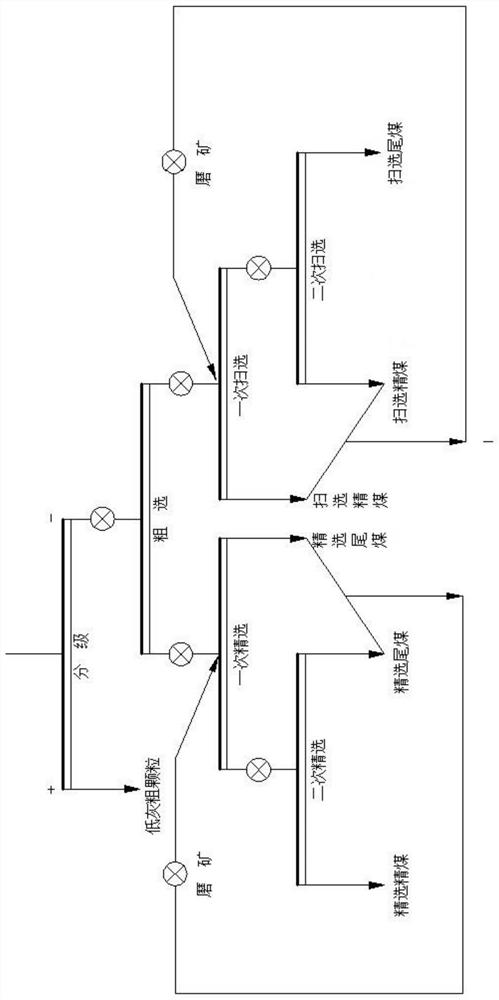

[0041] see figure 1 and figure 2 As shown, the present invention also provides a sorting method for a sorting system using gasification slag flotation and decarbonization, selecting the selection unit in the selection branch 200 and the sweeping unit in the sweeping branch 400. There are two sets, the selection unit and the sweeping unit are defined as the first-level and the second-level according to their serial order. The process flow of the sorting method is as follows:

[0042] 1) The powdered coal gasification slag 1 and water 2 are stirred to obtain the mixture material 3 by the stirring barrel A, and the mixture material 3 is transported to the cyclone classification screen C by the feeding pump B;

[0043] 2) The mixed material 3 is processed by the cyclone classification screen C to obtain the cyclone classification sieve bottom flow 4, the cyclone classification sieve overflow and the undersize 5 of the low ash coarse particle, wherein the cyclone classification s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com