Method for rapidly determining silver content in copper ore

A technology for rapid determination of copper ore, applied in measurement devices, preparation of test samples, measurement of color/spectral characteristics, etc., can solve the problems of high testing cost, unfriendly environment, and long time consumption, and improve testing efficiency. , the procedures are complicated and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

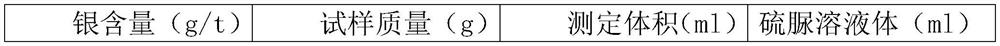

[0025] Take copper ore sample F-1, pulverize it through a 200-mesh sieve, dry it at 150°C for 1 hour, weigh 0.5g of the treated sample into a 250ml beaker, wet it with a small amount of water, add 8ml of perchloric acid, and heat Dissolve and evaporate to about 1ml of solution, and let stand to cool; then rinse the wall of the cup with water and add thiourea solution according to the standard in Table 1, heat to dissolve the solid substance, and after cooling, transfer the solution to a 100ml volumetric flask to constant volume, and put it in the atomic absorption chamber. After standing for two hours, atomic absorption spectrometry was carried out after clarification.

[0026] Table 1

[0027]

[0028]

Embodiment 2

[0030] Take the copper ore sample F-3, crush it through a 200-mesh sieve, dry it at 150°C for 1 hour, weigh 0.5g of the treated sample into a 250ml beaker, wet it with a small amount of water, add 8ml of perchloric acid, and heat Dissolve and evaporate to about 1ml of solution, and let stand to cool; then rinse the wall of the cup with water and add thiourea solution according to the standard in Table 1, heat to dissolve the solid substance, and after cooling, transfer the solution to a 100ml volumetric flask to constant volume, and put it in the atomic absorption chamber. After standing for two hours, atomic absorption spectrometry was carried out after clarification.

Embodiment 3

[0032] Take the copper ore sample F-11, crush it through a 200-mesh sieve, dry it at 150°C for 1 hour, weigh 0.5g of the treated sample into a 250ml beaker, wet it with a small amount of water, add 8ml of perchloric acid, and heat Dissolve and evaporate to about 1ml of solution, and let stand to cool; then rinse the wall of the cup with water and add thiourea solution according to the standard in Table 1, heat to dissolve the solid substance, and after cooling, transfer the solution to a 100ml volumetric flask to constant volume, and put it in the atomic absorption chamber. After standing for two hours, atomic absorption spectrometry was carried out after clarification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com