High-performance anti-scaling modified filter cloth for vacuum filter and preparation method of high-performance anti-scaling modified filter cloth

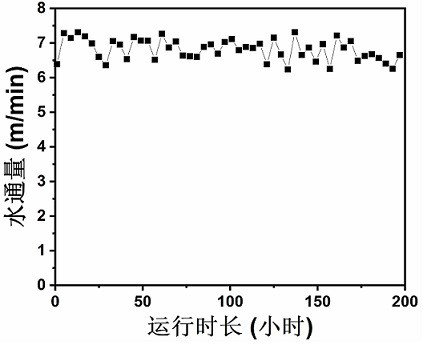

A vacuum filter, high-performance technology, applied in the field of separation, can solve the problems of prolonging the separation time and increasing the operating cost of the enterprise, and achieve high flux recovery rate, high water flux and flux recovery rate, and good modification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

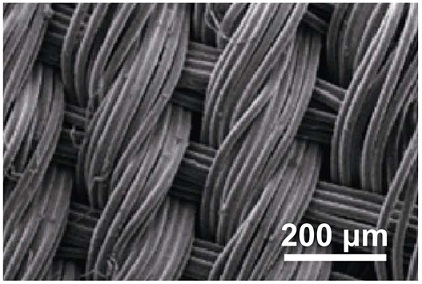

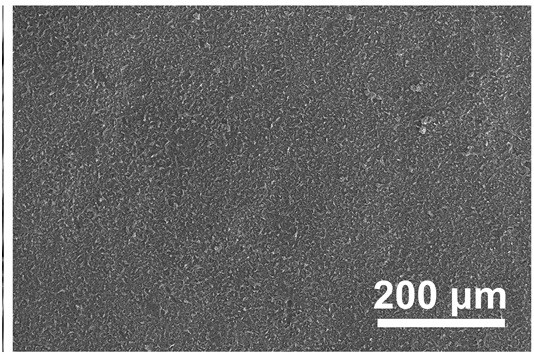

[0032] A preparation method of a high-performance anti-fouling modified filter cloth for a vacuum filter, comprising the following steps:

[0033] (1) Disperse the amphoteric polyacrylamide and carbon nanotubes in deionized water to prepare a modified solution, and ultrasonically treat the carbon nanotubes to uniformly disperse; the mass concentration of the amphoteric polyacrylamide in the modified solution is 0.1 wt%, and the carbon The mass concentration of nanotubes is 0.1wt%;

[0034] (2) Soak the polypropylene filter cloth into the modified solution prepared in step (1), take it out after 1 hour, and treat it at 50°C for 1 hour;

[0035] (3) dissolving polyvinylidene fluoride in chloroform to prepare a polyvinylidene fluoride solution with a mass concentration of 0.1 wt %, and soaking the filter cloth treated in step (2) in the polyvinylidene fluoride solution for 1 hour;

[0036] (4) Irradiate the filter cloth obtained in step (3) under ultraviolet light for 20 minutes...

Embodiment 2

[0038] A preparation method of a high-performance anti-fouling modified filter cloth for a vacuum filter, comprising the following steps:

[0039] (1) Disperse polysulfonate betaine and graphene oxide in deionized water to prepare a modified solution, and ultrasonically treat the graphene oxide to uniformly disperse the graphene oxide; the mass concentration of polysulfonate betaine in the modified solution is 2wt %, the mass concentration of graphene oxide is 5wt%;

[0040] (2) Immerse the polyethylene filter cloth in the modified solution prepared in step (1), take it out after 24 hours, and treat it at 70°C for 5 hours;

[0041] (3) dissolving polyvinylidene fluoride in chloroform to prepare a polyvinylidene fluoride solution with a mass concentration of 1wt%, and soaking the filter cloth processed in step (2) in the polyvinylidene fluoride solution for 5 hours;

[0042] (4) irradiating the filter cloth obtained in step (3) under ultraviolet light for 2 hours to obtain a h...

Embodiment 3

[0044] A preparation method of a high-performance anti-fouling modified filter cloth for a vacuum filter, comprising the following steps:

[0045] (1) Disperse the amphoteric polyacrylamide and silica in deionized water to prepare a modified solution, and ultrasonically treat the silica to uniformly disperse the silica; the mass concentration of the amphoteric polyacrylamide in the modified solution is 0.4 wt%, and the two The mass concentration of silicon oxide is 0.8wt%;

[0046] (2) Soak the polyphenylene sulfide filter cloth into the modified solution prepared in step (1), take it out after 2 hours, and treat it at 60°C for 3 hours;

[0047] (3) dissolving polyvinylidene fluoride in chloroform to prepare a polyvinylidene fluoride solution with a mass concentration of 0.5wt%, and soaking the filter cloth treated in step (2) in the polyvinylidene fluoride solution for 3 hours;

[0048] (4) irradiating the filter cloth obtained in step (3) under ultraviolet light for 40 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com