Cutting tool wear state monitoring method based on noise analysis

A cutting tool and wear state technology, applied in the field of cutting tool wear measurement and monitoring of CNC machine tools, can solve problems such as inability to apply mass production, affecting the normal processing of machine tools, troublesome sensor installation, etc., to break through technical bottlenecks, realize real-time monitoring, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

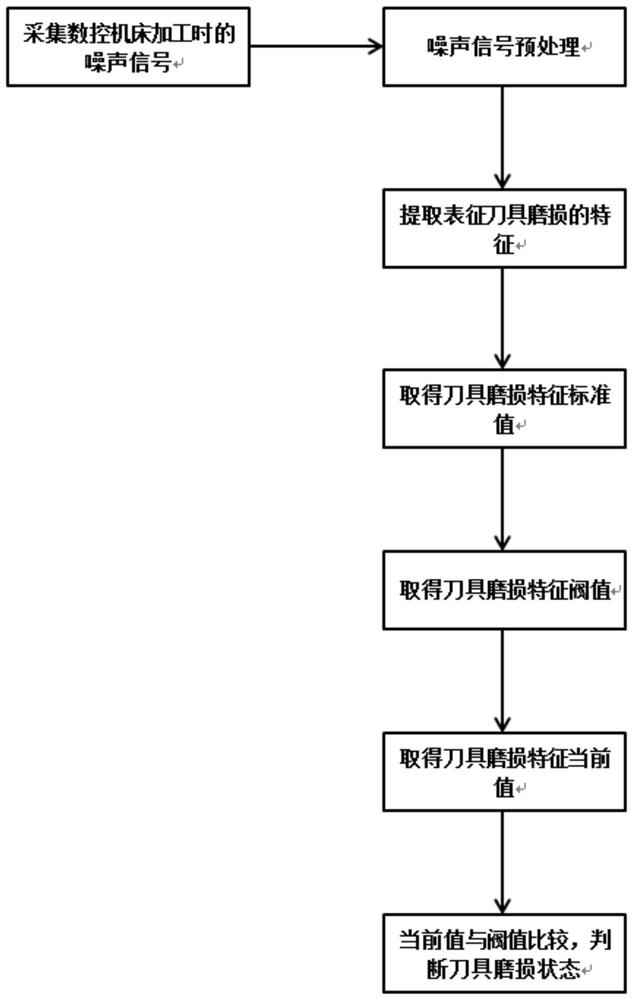

[0029] see figure 1 As shown, a method for monitoring the wear state of cutting tools based on noise analysis of the present invention is to collect noise signals during CNC machine tool processing, and after a series of signal processing and analysis, extract key features that can characterize tool wear, and compare wear. Feature current value and feature threshold value to realize real-time monitoring of tool wear status.

[0030] In this embodiment, the method for monitoring the wear state of cutting tools based on noise analysis mainly includes the following steps:

[0031] Step (1): Collect the noise signal of the CNC machine tool when the cutting tool is working; this embodiment is to use the monitoring of the milling tool wear when the CNC milling machine processes the aluminum alloy thin-walled parts as an example to illustrate the noise analysis-based cutting tool Wear condition monitoring method. In this embodiment, the capacitive noise sensor is used to collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com