An Intelligent Tool Fault Diagnosis Method

A fault diagnosis and tool technology, applied in the direction of manufacturing tools, metal processing mechanical parts, measuring/indicating equipment, etc., can solve the problems of high labor cost, tool fault diagnosis is not linear and intelligent, and economical cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] The present invention provides a kind of intelligent tool fault diagnosis method, it comprises the following steps:

[0038] 1) A PLC is set between the CNC end (computer numerical control end) of the machine tool and the machine tool end, and the PLC realizes input and output signal processing on the machine tool side and the CNC side.

[0039] 2) The PLC acquires several tool vibration signals x(t) generated during machine tool processing, and processes the collected tool vibration signals x(t) to extract tool features:

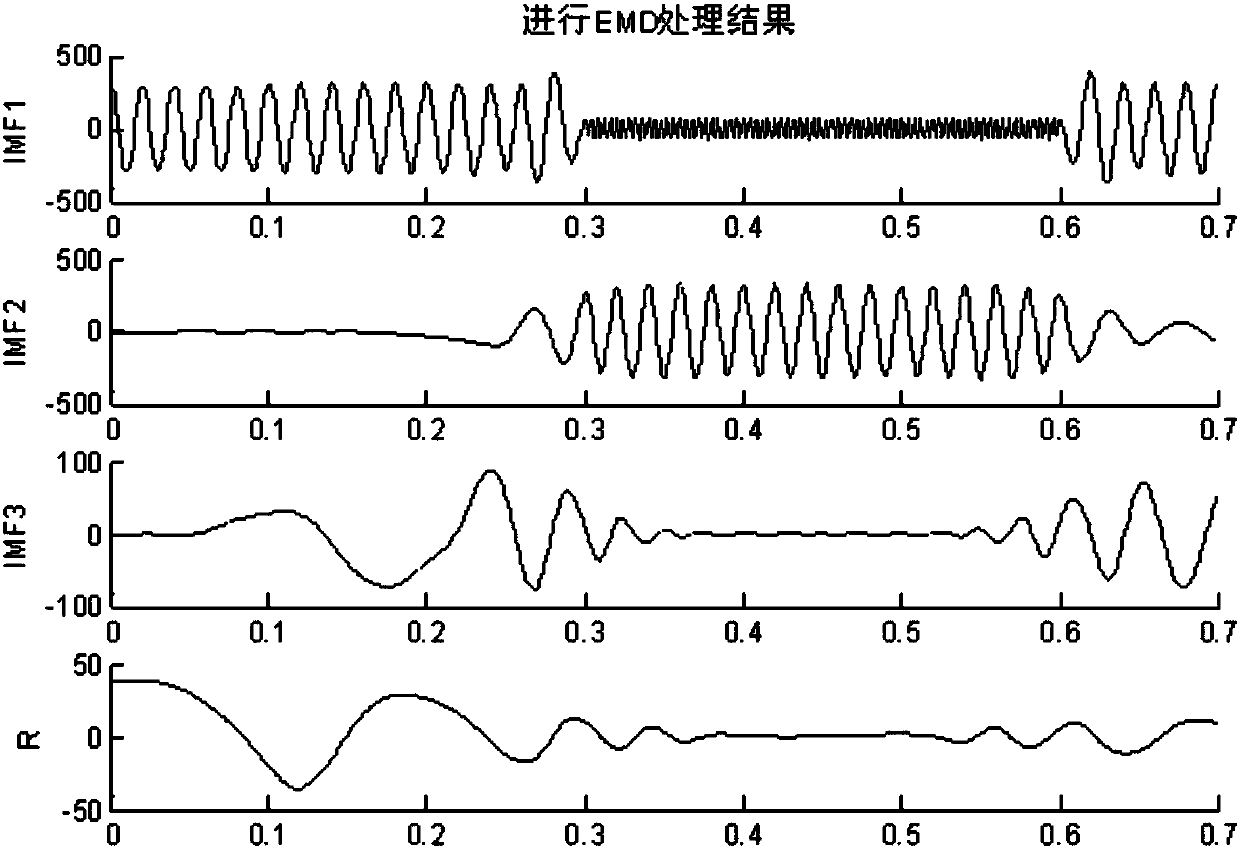

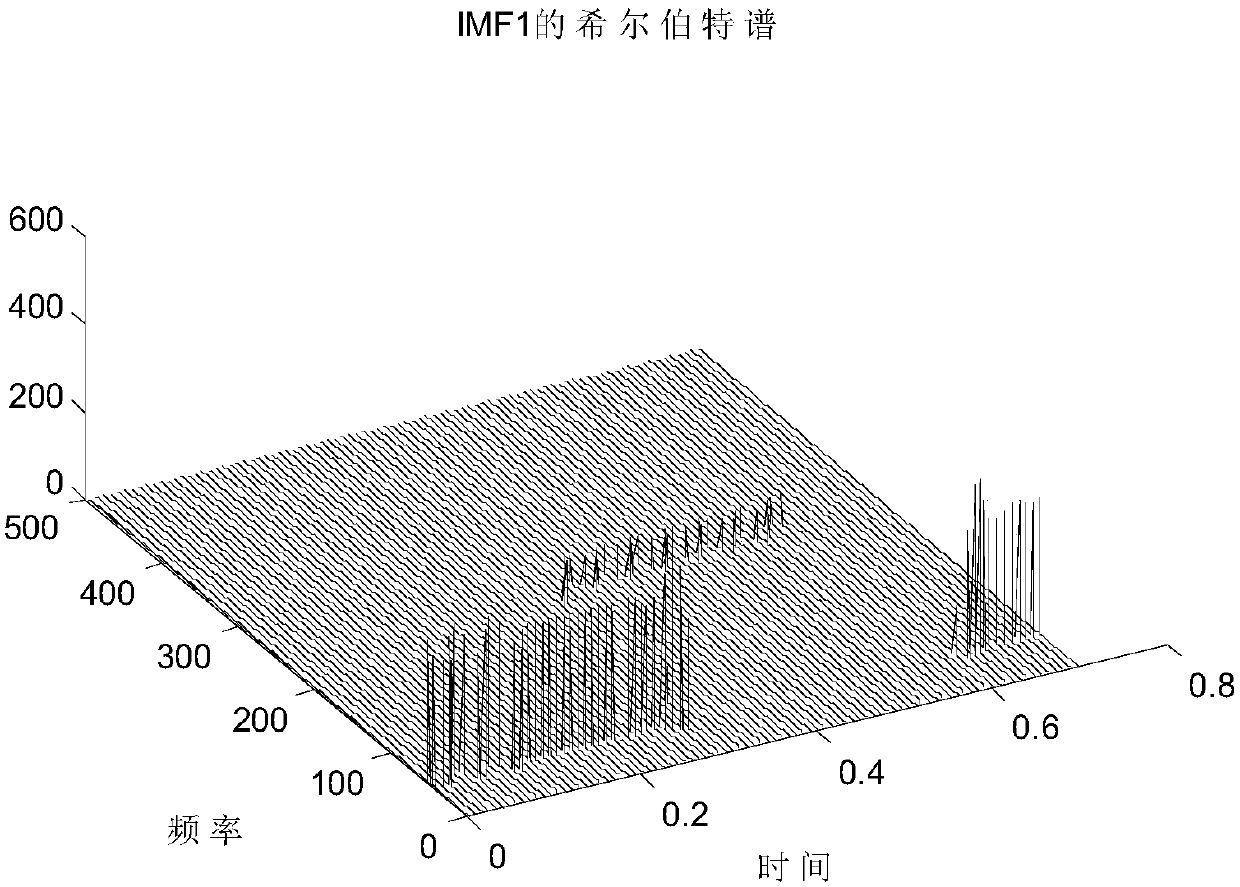

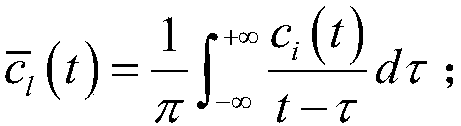

[0040] 2.1) Perform empirical mode decomposition on the collected tool vibration signal x(t), decompose the fluctuations or trends of different scales in the tool vibration signal x(t) step by step, and generate data sequences with different characteristic scales. These sequences are defined as Intrinsic Mode Functions (IMF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com