Biomass functional material for antibiotic adsorption and preparation method thereof

A functional material and biomass technology, which is applied in the deep processing of agricultural and forestry solid waste resources and environmental governance, can solve the problems of narrow application range of adsorption materials, long adsorption time, and production of other by-products, and achieve good adsorption effect of antibiotics and high adsorption capacity. Enhanced, convenient and efficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a basic biomass functional material for antibiotic adsorption, comprising the following steps:

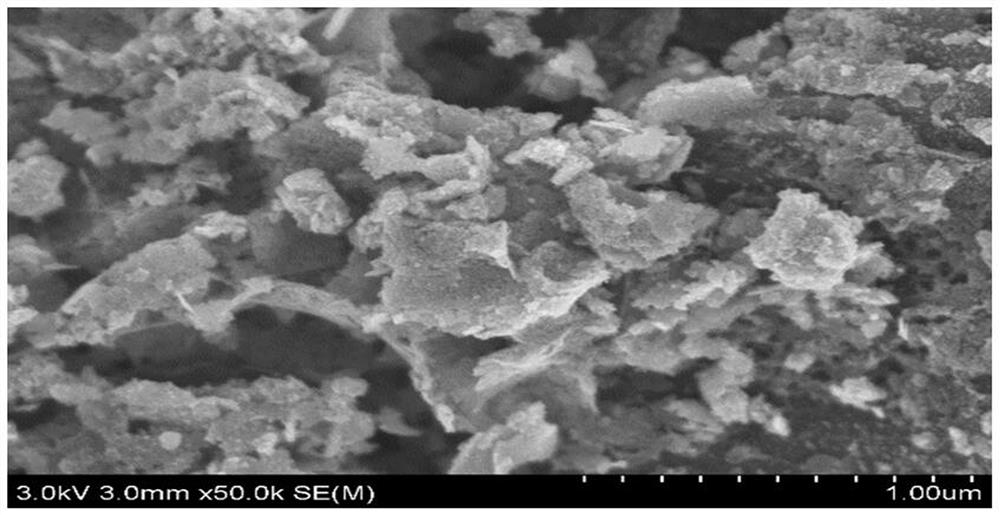

[0048] (1) Dissolve 3.0 g of 15.0% persimmon tannin extract powder and 1.50 g of biochar in 100 mL of water, filter out insoluble impurities, and prepare 2.5 mL of glutaraldehyde aqueous solution with a mass fraction of 25.0% as cross-linking agent;

[0049] (2) Turn on the stirrer, vigorously stir the mixed solution of persimmon tannin extract and biochar at 25°C for 8 hours, and then adjust to 40°C and add 25% glutaraldehyde aqueous solution for cross-linking and curing for 8 hours; the preparation speed ranges from 300 to 1200 between rpm;

[0050] (3) Wash the cross-linked solidification with distilled water, filter, and vacuum dry at 50 °C for 20 h. Pulverize the material and sieve it to fine particles to obtain basic biomass functional materials for further use;

[0051] (4) Select oxytetracycline discharge wastewater with oxytetracycline conc...

Embodiment 2

[0056] A method for preparing basic biomass functional materials for antibiotic adsorption, comprising the following steps:

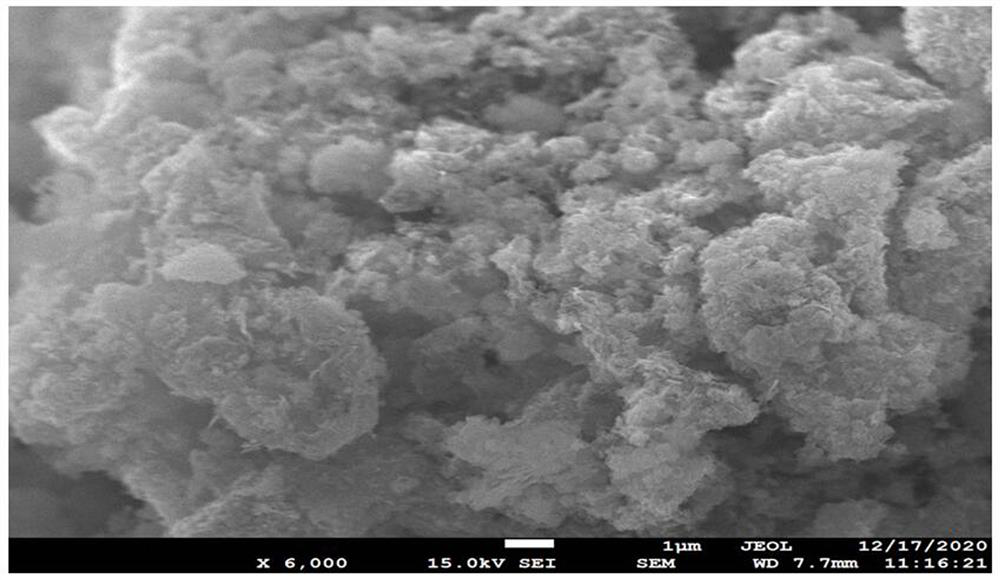

[0057] (1) Dissolve 3.0 g of persimmon tannin extract with 15.0% persimmon tannin and nitrogen-doped graphene in 100 mL of water, filter out insoluble impurities, and prepare 2.5 mL of 25.0% glutaraldehyde aqueous solution as cross-linking agent;

[0058] (2) Turn on the stirrer, stir the mixed solution of persimmon tannin extract and nitrogen-doped graphene at 25°C for 20h, then adjust to 40°C, add glutaraldehyde aqueous solution for cross-linking and curing for 20h; the stirring speed range is in Between 300 and 1200 rpm;

[0059] (3) Wash the cross-linked and solidified samples with distilled water and filter them, and vacuum dry them at 50°C for 20 hours; pulverize and sieve the materials to obtain basic biomass functional materials for further use;

[0060] (4) Select wastewater discharged from hospitals, pharmaceutical factories and other places...

Embodiment 3

[0065] A preparation method of a gel state biomass functional material for antibiotic adsorption, comprising the following steps:

[0066] (1) Preparation of water phase: Dissolve 3.0 g of the basic biomass functional material obtained in Example 2 in 100 mL of water, filter out insoluble impurities, and prepare 2.5 mL of N,N-methylenebisacrylamide with a concentration of 20%. Aqueous amide solution as crosslinking agent;

[0067] (2) Preparation of oil phase: 10ml of cyclohexane, 5ml of glycerol and 5ml of gluconolactone each were mixed into an oil phase system;

[0068] (3) Turn on the stirrer at 300-1200 rpm and stir the water phase system for 8h, then add 2.5ml, 25.0% glutaraldehyde for crosslinking and curing for 8h, wash away impurities with distilled water, and add the oil phase system of step (2) to mix at the same time uniform;

[0069] (4) Mix the water phase and the oil phase, add 100 ml of calcium carbonate solution with a concentration of 1 mol / L, and mix by ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com