Immersed liquid cooling system and control method

A control method and immersion technology, which is applied in the field of immersion liquid cooling system and control, and can solve the problems of battery adjustment and poor compatibility in the battery liquid cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

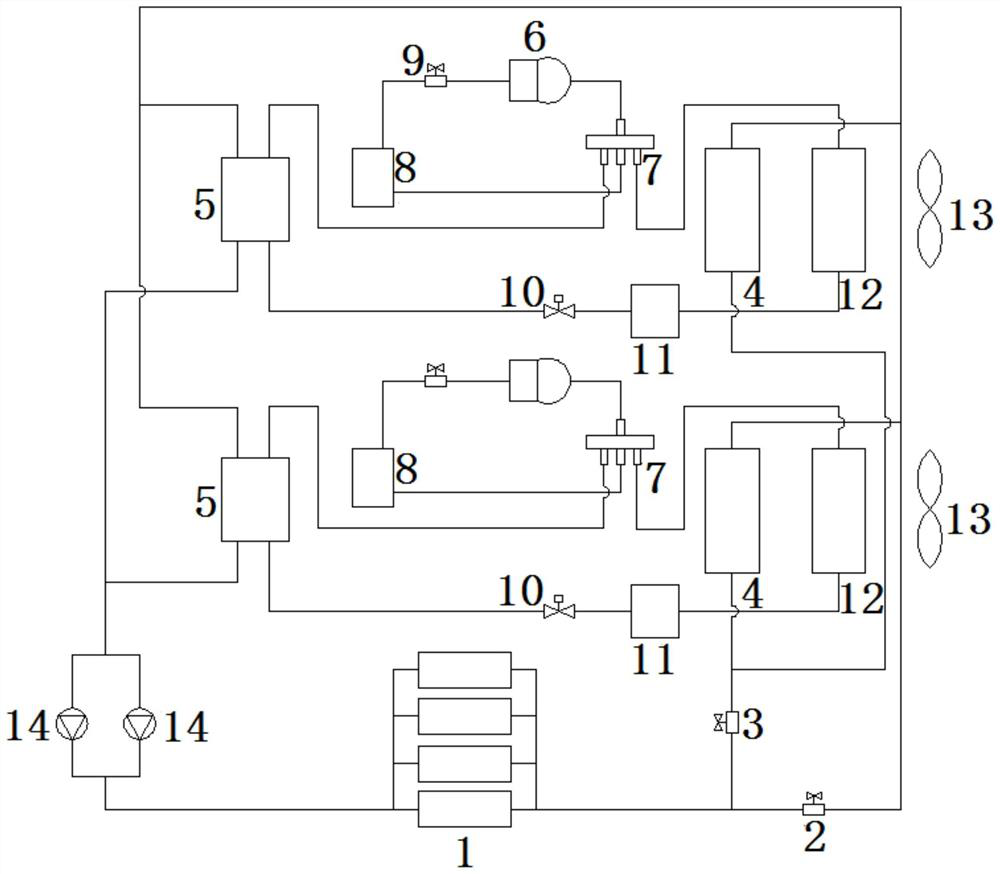

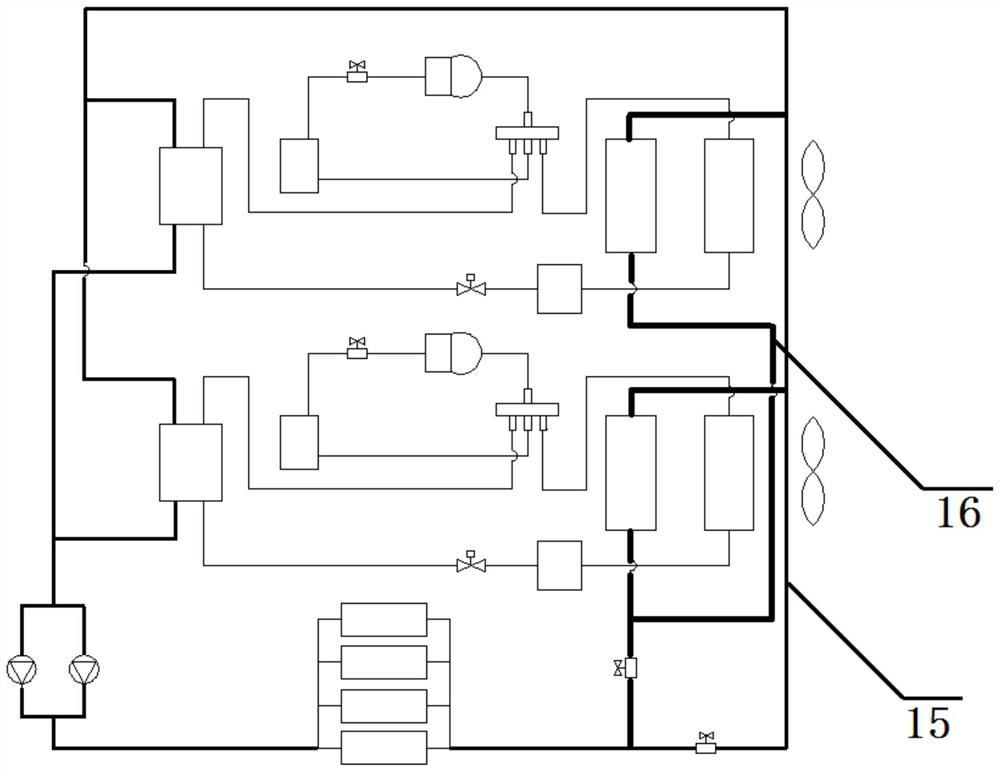

[0053] see figure 1 with figure 2 , an immersion liquid cooling system provided in this embodiment, comprising:

[0054] Circulation pump 14, first delivery pipeline 15, second delivery pipeline 16, natural cooling heat exchange device, cooling and heating device, and heat exchange fluid supply device 1 for loading heat exchange fluid for adjusting battery temperature;

[0055] The heat exchange fluid supply device 1, the cooling and heating device and the circulation pump 14 are connected in series through the first delivery pipeline 15, and the first solenoid valve 2 is connected to the first delivery pipeline 15, The first solenoid valve 2 is located between the heat exchange fluid supply device 1 and the cooling and heating device;

[0056] The inlet of the second delivery pipeline 16 is connected to the outlet of the heat exchange fluid supply device 1, the outlet of the second delivery pipeline 16 is connected to the first delivery pipeline 15, and the second delivery...

Embodiment 2

[0079] see figure 1 with figure 2 , a control method for an immersion liquid cooling system provided in this embodiment, including:

[0080] This control method is used in the submerged liquid cooling system in Embodiment 1, which specifically includes:

[0081] Cooling and heating device cooling mode:

[0082] When the detected ambient temperature>the first preset ambient temperature, run the cooling mode of the cooling and heating device;

[0083] When the first preset battery temperature>the detected battery temperature>the second preset battery temperature, the first solenoid valve 2 is opened, the second solenoid valve 3 is closed, a single cooling and heating device is turned on, and it operates in cooling mode, Until the detected battery temperature < standard preset battery temperature;

[0084] When the detected battery temperature > the first preset battery temperature, both cooling and heating devices are turned on, and the cooling mode is turned on at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com