Automatic desizing and leveling equipment

A desizing and equipment technology, which is applied to the processing of textile material drums, textiles and papermaking, and textile material processing, can solve the problems of operator inconvenience, low efficiency, and non-adjustable distance between cloth guide rollers, etc., to improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

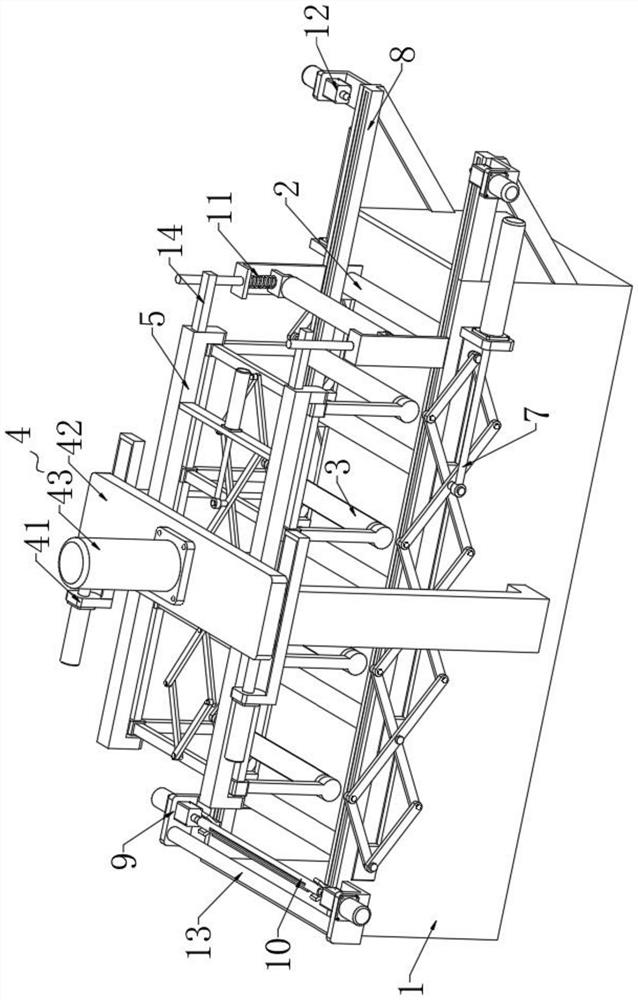

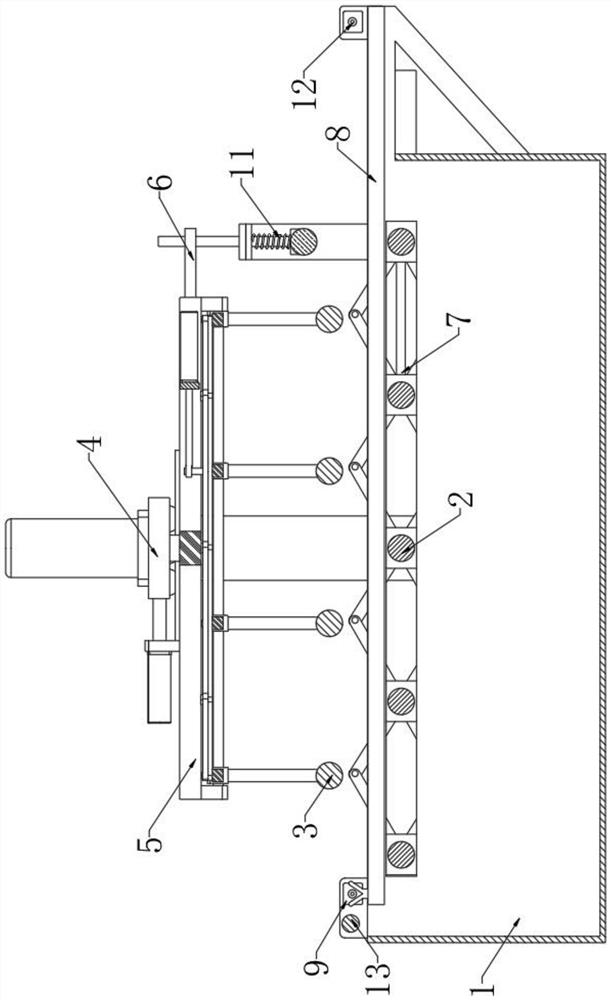

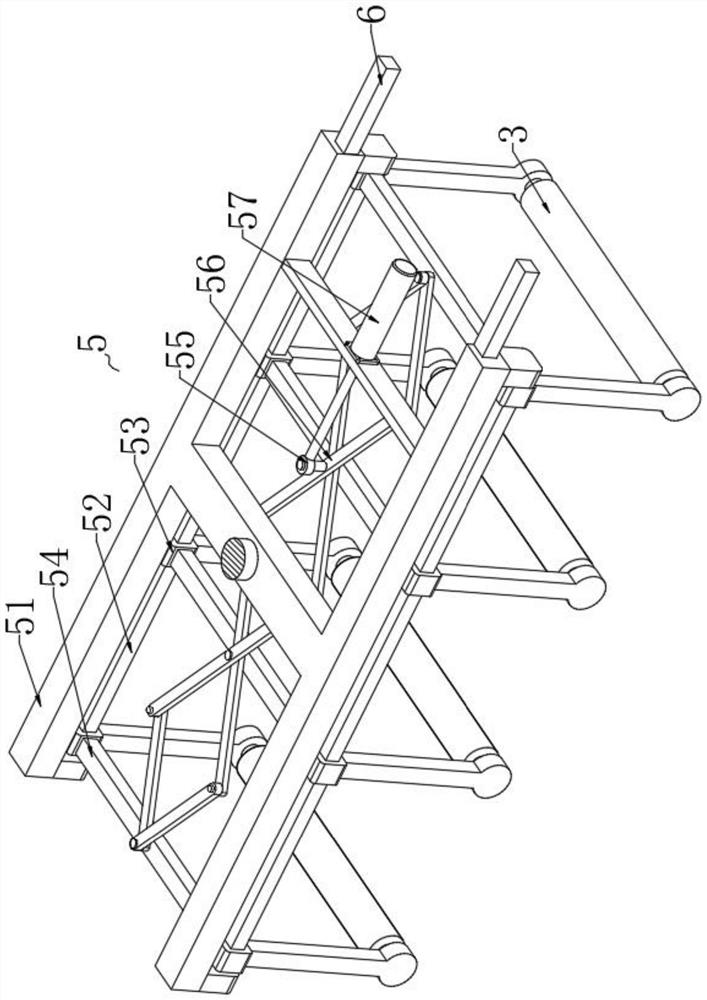

[0032] Such as Figure 1-5 As shown in the figure, a kind of automatic desizing and leveling equipment proposed by the present invention includes a desizing water tank 1, and a plurality of cloth guide rollers a2 with adjustable spacing are laterally distributed on the upper half of the desizing water tank 1, and the cloth guide rollers a2 pass through The adjustment mechanism a7 adjusts the spacing. The adjustment mechanism a7 includes an elongated sliding hole 71 opened on the side wall of the desizing water tank 1. A plurality of sliders 72 are slidably arranged in the elongated sliding hole 71. The cloth guide roller a2 is rotatably installed on a symmetrical Two sliders 72, and multiple sliders 72 are synchronously driven through the scissor structure a73, the outside of the desizing water tank 1 is fixed with a telescopic push rod c74 through the installation plate a, and the telescopic end of the telescopic push rod c74 is fixed with a connecting sleeve a75, and the con...

Embodiment 2

[0038] Such as figure 2 , 11 As shown, the automatic desizing and leveling equipment proposed by the present invention, compared with the first embodiment, this embodiment also includes a leveling mechanism fixed to the desizing water tank 1 on the upper side of the fabric guide roller a2 on the most side 11. The leveling mechanism 11 includes an L-shaped frame 111 fixed on both sides of the desizing water tank 1. The upper side of the L-shaped frame 111 is slidably provided with a vertical slider 112, and the lower side of the vertical slider 112 is fixed with an L-shaped bracket 113. Between the two L-shaped brackets 113, a leveling roller 114 corresponding to the cloth guide roller a2 on the most side is installed in rotation, and a tension spring b115 sleeved on the vertical slide bar 112 is fixed between the L-shaped bracket 113 and the L-shaped frame 111 , the upper side of the L-shaped bracket 113 is fixed with a rubber buffer block 116, and the cross bar of the H-sha...

Embodiment 3

[0041] Such as Figure 6-10 As shown, an automatic desizing and leveling equipment proposed by the present invention, compared with Embodiment 1 or Embodiment 2, this embodiment also includes that the traction mechanism 8 includes electric slides fixed on the inner side walls of the desizing water tank 1 81, the mobile end of the electric sliding table 81 is fixed with a positioning frame 82, and the positioning frame 82 is a V-shaped structure or an arc-shaped structure;

[0042] The cloth winding member 10 includes a cloth winding roller 101, the cloth winding roller 101 is provided with a threading through hole 102, and one side of the threading through hole 102 slides through and is provided with a blocking block 103, and both sides of the blocking block 103 are provided with a cloth winding roller. The inner cavity 105 of 101, the inner cavity 105 is provided with a connecting block fixed to the block 103, and a tension spring a106 is arranged between the connecting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com