Photovoltaic EVA packaging adhesive film cutting machine capable of preventing wrinkles

A technology of encapsulating film and cutting machine, which is applied to the cleaning method of tools, transportation and packaging, cleaning methods and utensils, etc., which can solve the problem of easy wrinkles, no anti-wrinkle, and dust removal and cleaning on the surface of photovoltaic EVA encapsulation film and other problems, to achieve the effect of reducing wrinkles and smoothing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

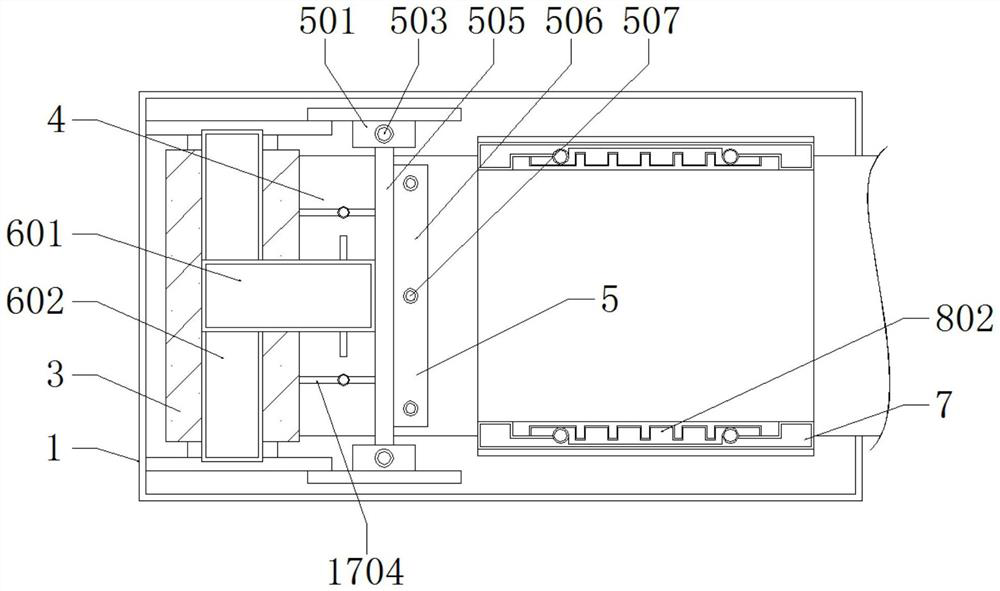

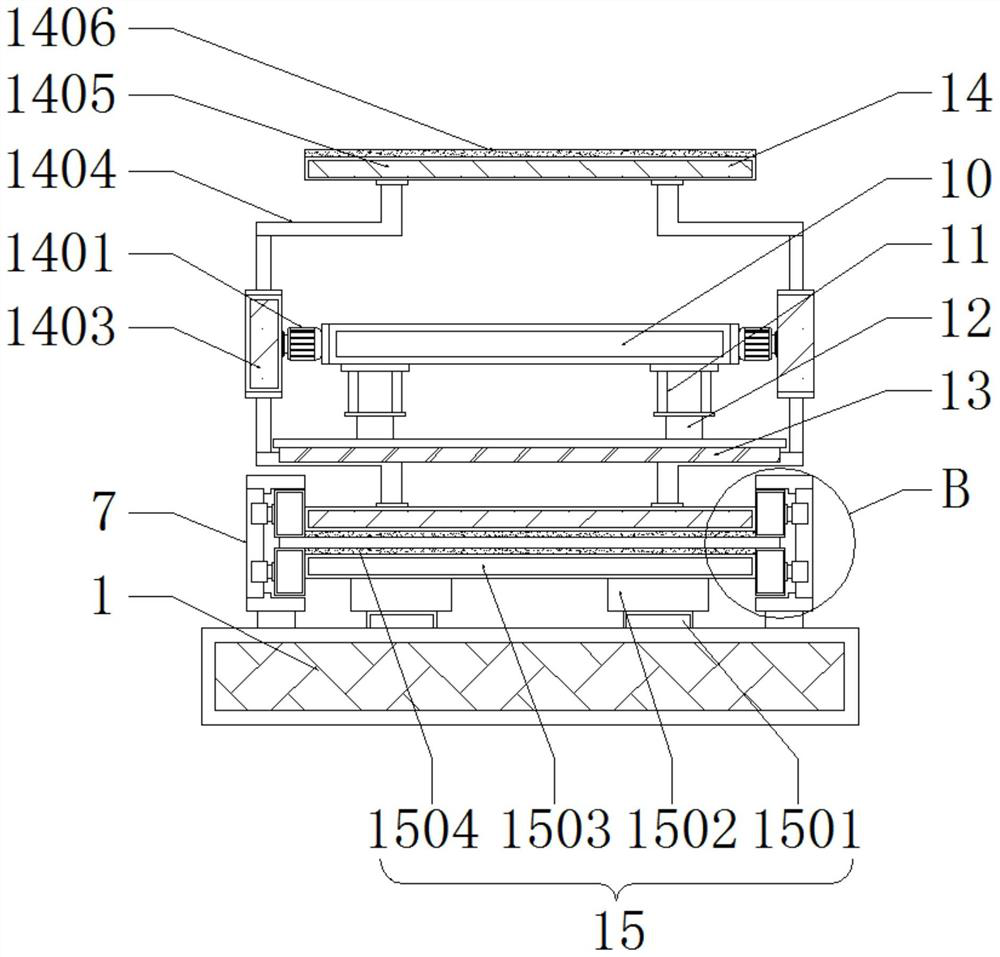

[0034] see Figure 1 to Figure 9 , the present invention provides a technical solution: a photovoltaic EVA packaging film cutting machine with anti-wrinkle, including a workbench 1, a leveling assembly 6 and a side frame 7, a bracket 2 is installed on the upper left side of the workbench 1, and the bracket 2 An adhesive film roller 3 is installed for rotation inside, and an EVA adhesive film 4 is arranged on the outside of the adhesive film roller 3, and a driving assembly 5 is installed on the upper middle side of the workbench 1, and the leveling assembly 6 is arranged on one side of the driving assembly 5, and is flat Component 6 includes connecting plate 601, fixed frame 602, movable rotating shaft 603, leveling roller 604, damping rotating shaft 605, extension rotating rod 606 and cleaning cotton 607, one side of connecting plate 601 is equipped with fixed frame 602, and the inside of fixed frame 602 The leveling roller 604 is installed by rotating the movable rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com