Water-blocking power cable

A power cable and water blocking technology, applied in the field of power cables, can solve the problems of poor waterproof performance of cables, poor protection measures of power cables, cable wear, etc., and achieve the effect of improving waterproofness and avoiding the phenomenon of water tree branches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

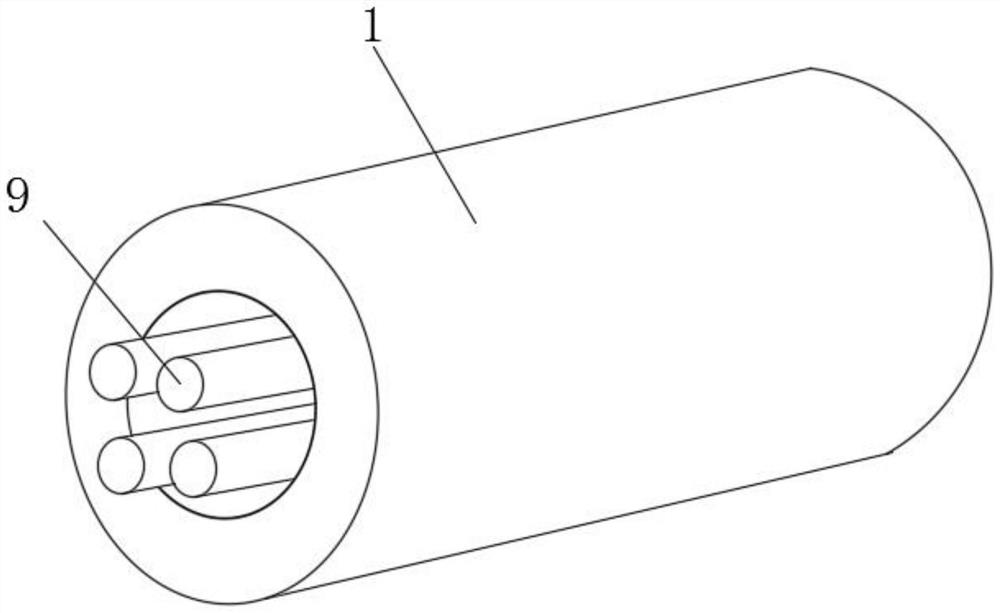

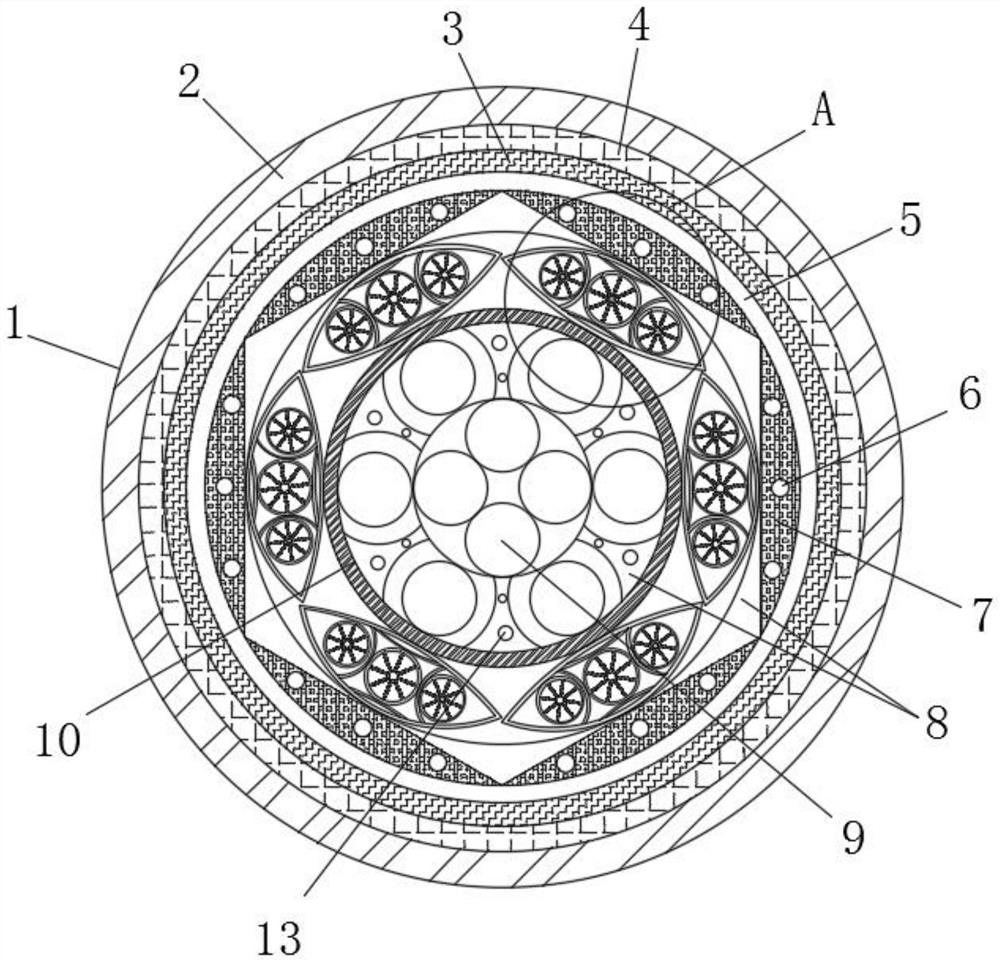

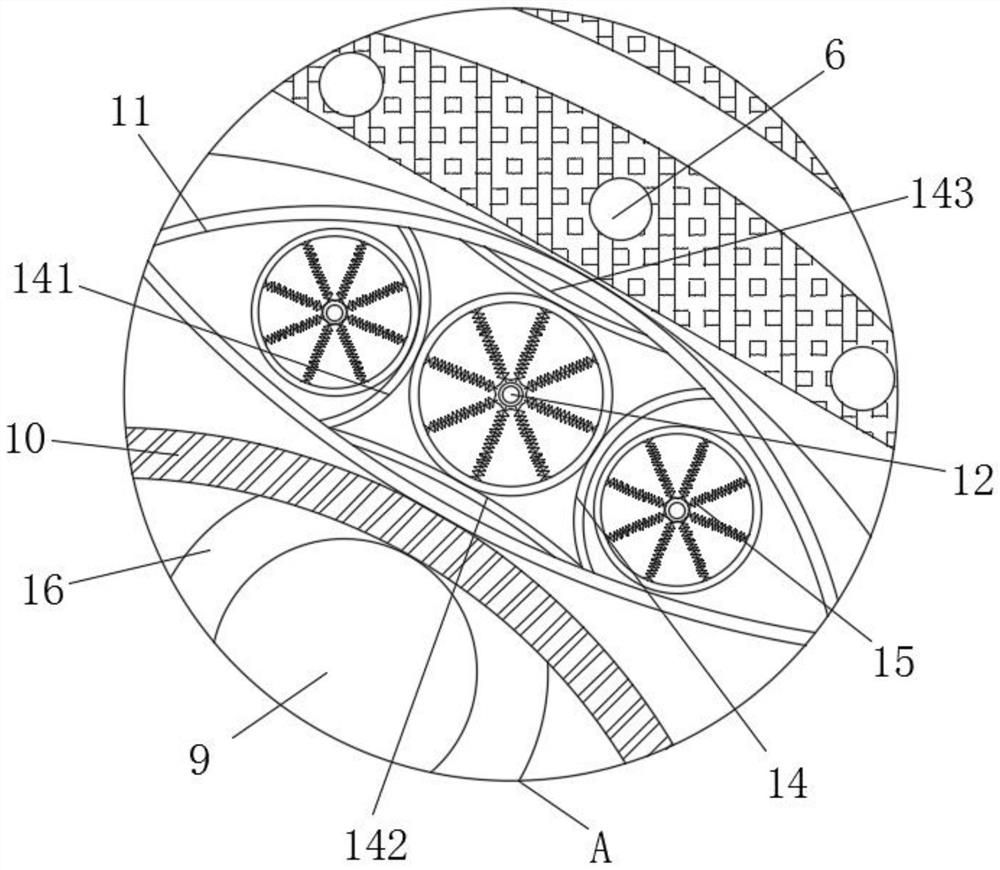

[0040] as Figure 1-8 As shown, the present invention provides a water-blocking power cable, comprising a cable body 1, the cable body 1 is provided with a waterproof layer 2, the internal of the waterproof layer 2 is provided with a reinforced support ring 10, the outer wall of the reinforced support ring 10 is fixed connected to the arc support shrapnel 11, the inner wall of the arc support shrapnel 11 is fixed connected to the first undertake shrapnel 142, the first undertake shrapnel 142 is provided above the second undertakening shrapnel 143, the inner wall of the curved support shrapnel 11 is fixed connected to the second built-in support shrapnel 141, The upper surface of the first bearing shrapnel 142 is fixedly connected to the first elastic support assembly 12, and the outer wall of the curved support shrapnel 11 is fixedly connected with filler 8.

[0041]In the process of the arc support shrapnel 11 is squeezed, the first elastic support component 12 and the second ela...

Embodiment 2

[0046] as Figure 1-8As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the bottom end of the scattering spring 21 is fixed with the outer wall of the built-in flex 22, the outer wall of the built-in flex 22 is fixed to be connected to an external reinforcing strip 23, the inner wall of the reinforcing support ring 10 is fixed connected to the protective layer 16, the inner wall of the protective layer 16 is fixed to the guide core 9, the outer wall of the guide 9 is fixed to be connected to the separator layer 24, the outer wall of the waterstop bar 6 is fixed to be connected to the anti-cut layer 5, by the separation layer 24 of the outer surface of the core 9 is socketed, And the protective layer 16 of the outer wall of the separation layer 24 and the reinforced support ring 10, the guide core 9 and the earth and the different phases of the guide core 9 are electrically isolated from each other, so that each grid layer in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com