Food drying machine facilitating material turning

A technology for drying and turning materials for food is applied in the field of food dryers that are easy to turn materials, which can solve problems such as low efficiency and labor consumption, and achieve the effects of saving raw material resources, turning thoroughly and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

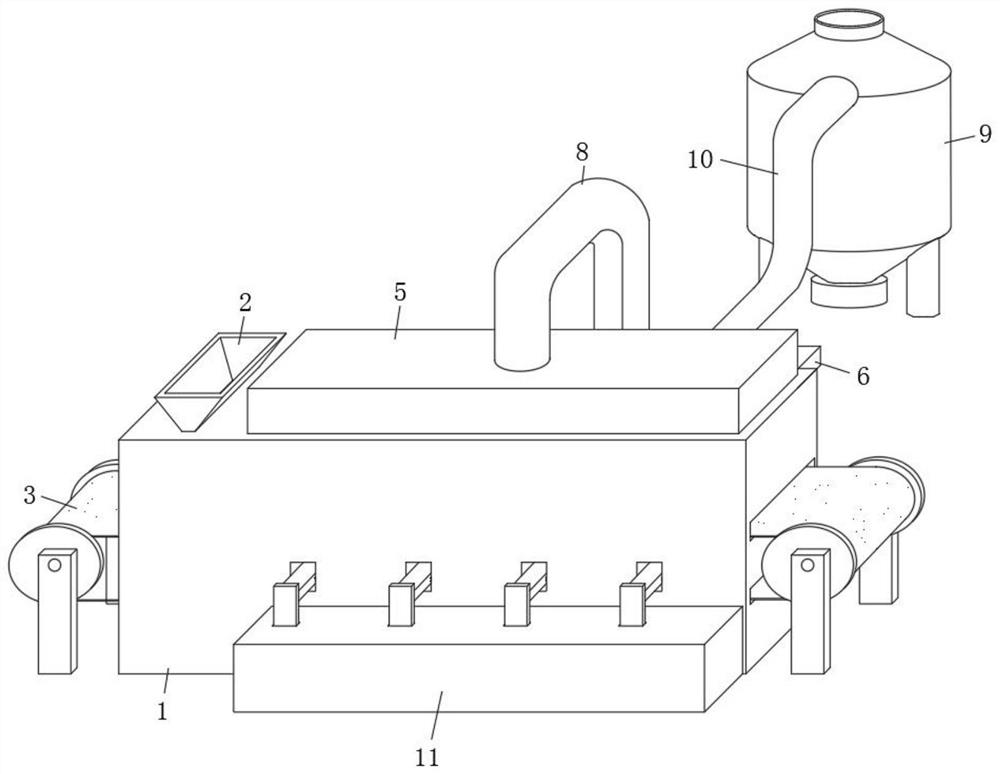

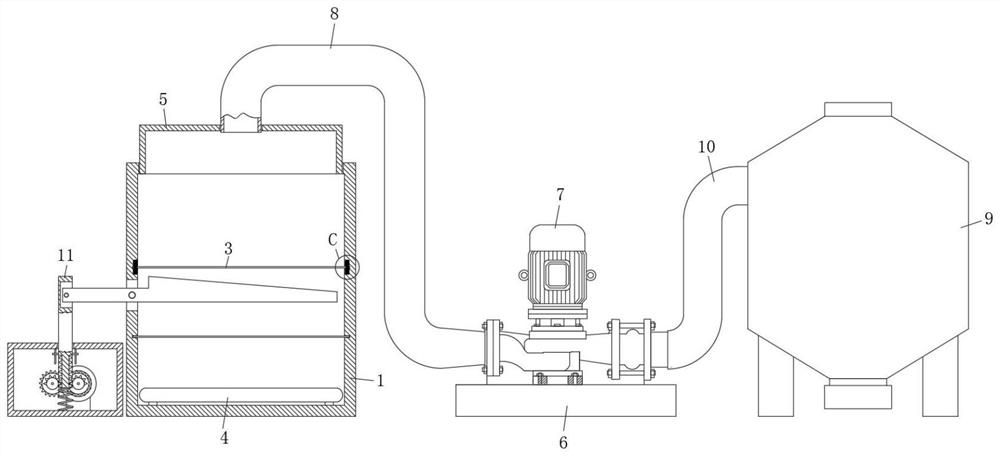

[0031] refer to figure 1 , 2 And 8, a kind of food drying machine that is convenient for material turning, comprises a drying box 1, a feeding hopper 2 is connected through the top side of the drying box 1, a conveyor belt 3 is installed on the inner side of the drying box 1, and the inside of the drying box 1 The bottom surface is also fixed with an electric heating tube 4, the top surface of the drying box 1 is also connected with a gas collecting dish 5, the rear side of the drying box 1 is also fixed with a mounting seat 6, and the top surface of the mounting seat 6 is fixed with an air pump body 7 by screws. An air extraction pipe 8 is connected between the input end of the air pump body 7 and the top surface of the gas collection dish 5, and a cyclone collector 9 is installed on the rear side of the mounting base 6, and the output end of the air pump body 7 is connected to the input end of the cyclone collector 9. There is an air pipe 10, and a beating mechanism 11 for ...

Embodiment 2

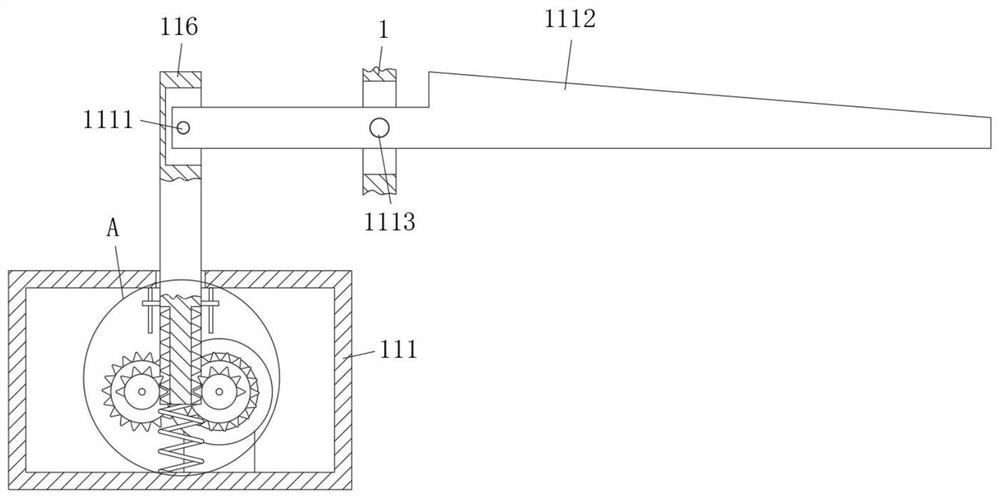

[0034] Such as Figure 1-6As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the beating mechanism 11 includes a drive box 111 installed on the front side of the drying box 1, and the inner walls of both sides of the drive box 111 are rotatably connected with a drive rod 112, and the drive rod 112 There are two and symmetrically distributed on the front and rear sides of the driving box 111, and the two driving rods 112 are rotationally connected by two gear sets with the same specifications. The inner bottom surface of the driving box 111 is also welded with a fixed seat 113. The fixed seat 113 The top surface is fixedly connected with a servo motor 114 by screws, and the output end of the servo motor 114 is fixedly connected with one of the driving rods 112. The outer wall of the driving rod 112 is also fixed with a driving gear 115, and the middle part of the top surface of the driving box 111 is also slidably connected with a driving plate 1...

Embodiment 3

[0037] Such as figure 2 and 7 As shown, this embodiment is basically the same as Embodiment 2. Preferably, the beating plate 1112 includes a horizontal section 1112A and an inclined section 1112B. One side of the drying box 1 is inclined downward toward the side of the mounting seat 6 .

[0038] In this embodiment, the beating plate 1112 is provided with a horizontal section 1112A and an inclined section 1112B, so that the beating plate 1112 can be in close contact with the upper surface of the beveling section 1112B when the beating plate 1112 is beating, thereby increasing the stress area of beating , thus ensuring the quality of material turnover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com