Preparation method of acetyl glycyrrhetinic acid

A technology of glycyrrhetinic acid and monoammonium glycyrrhizinate, which is applied in the fields of steroids and organic chemistry, can solve the problems of large organic solvent loss, cumbersome preparation process, and high cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

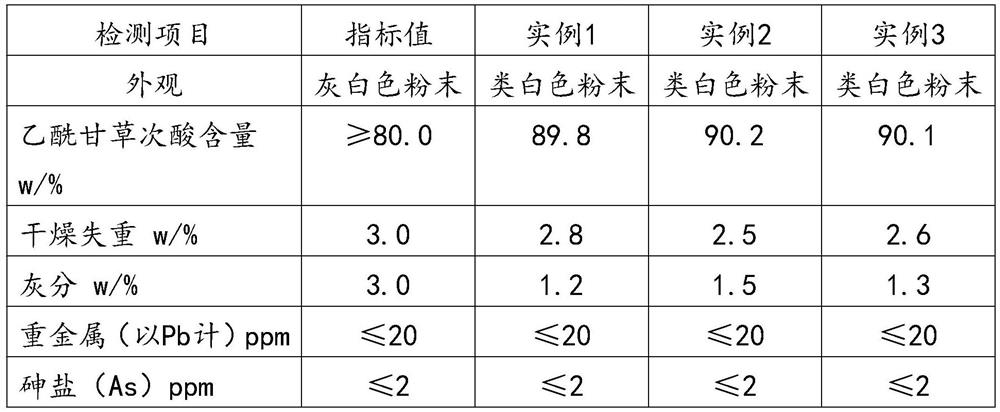

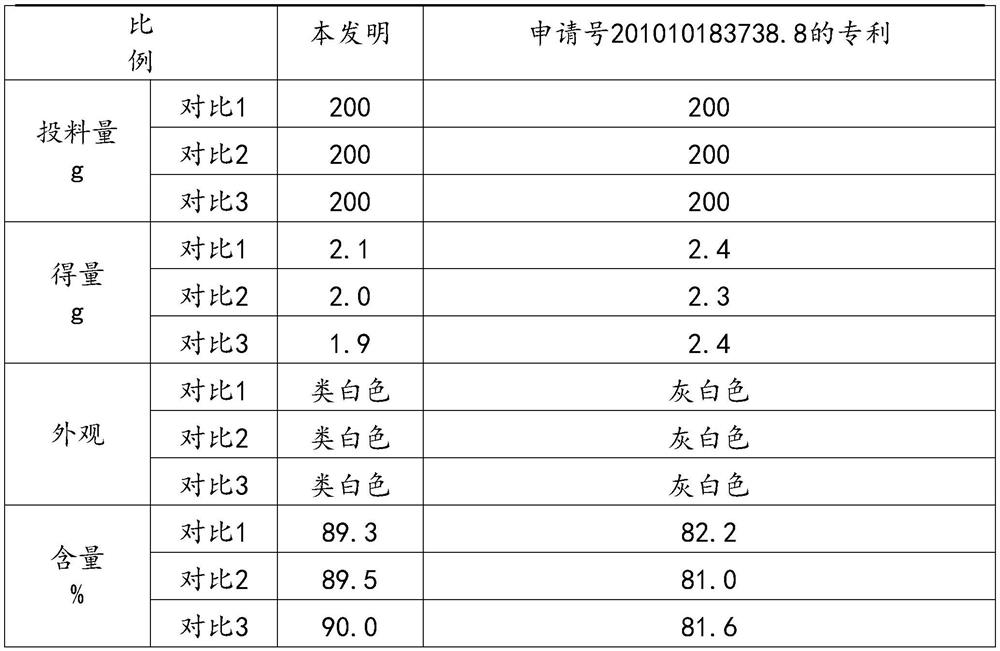

Embodiment 1

[0034] A preparation method of acetylglycyrrhetinic acid, prepared by the following steps:

[0035] Get 100kg of the dry product of monoammonium glycyrrhizinate mother liquor, add 450kg of glacial acetic acid with a concentration of 85% and stir to dissolve to obtain a mixed solution, then add 20kg of sulfuric acid to the mixed solution, heat up to 90°C, and react for 1.5h to carry out hydrolysis and acetylation. After the above reaction is completed, feed cooling water to reduce the temperature of the reaction system to 40°C, filter, wash with 100kg of glacial acetic acid with a concentration of 65%, then wash with water to pH 5, and dry at 85°C to obtain acetylglycyrrhetinic acid 10.8 kg.

Embodiment 2

[0037] A preparation method of acetylglycyrrhetinic acid, prepared by the following steps:

[0038] Get 120kg of the dry product of monoammonium glycyrrhizinate mother liquor, add 550kg concentration and be 85% glacial acetic acid and stir and dissolve to obtain a mixed solution, then add 30kg of sulfuric acid in the mixed solution, heat up to 95°C, react for 1.5h to carry out hydrolysis and acetylation reaction, After the above reaction is completed, feed cooling water to reduce the temperature of the reaction system to 40°C, filter, wash with 120kg of glacial acetic acid with a concentration of 65%, then wash with water to pH 5.5, and dry at 85°C to obtain acetylglycyrrhetinic acid 12.24 kg.

Embodiment 3

[0040] A preparation method of acetylglycyrrhetinic acid, prepared by the following steps:

[0041] Get 220kg of the dry product of monoammonium glycyrrhizinate mother liquor, add 1000kg concentration and be 85% glacial acetic acid and stir and dissolve to obtain a mixed solution, then add 60kg of sulfuric acid in the mixed solution, heat up to 98°C, react for 1.5h to carry out hydrolysis and acetylation reaction, After the above reaction is completed, feed cooling water to reduce the temperature of the reaction system to 40°C, filter, wash with 250kg of glacial acetic acid with a concentration of 65%, then wash with water to pH 6, and dry at 85°C to obtain acetylglycyrrhetinic acid 22.5 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com