Wort manufacturing method capable of improving wort filtration performance and increasing fermentable sugar content

A technology of filtering performance and fermentable sugar, which is applied in the field of malt and wort manufacturing, can solve the problems of low fermentable sugar content and poor filtering performance of wort, and can reduce the content of β-glucan in malt and increase the content of malt. Juice filtration performance and fermentable sugar content, effect of simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

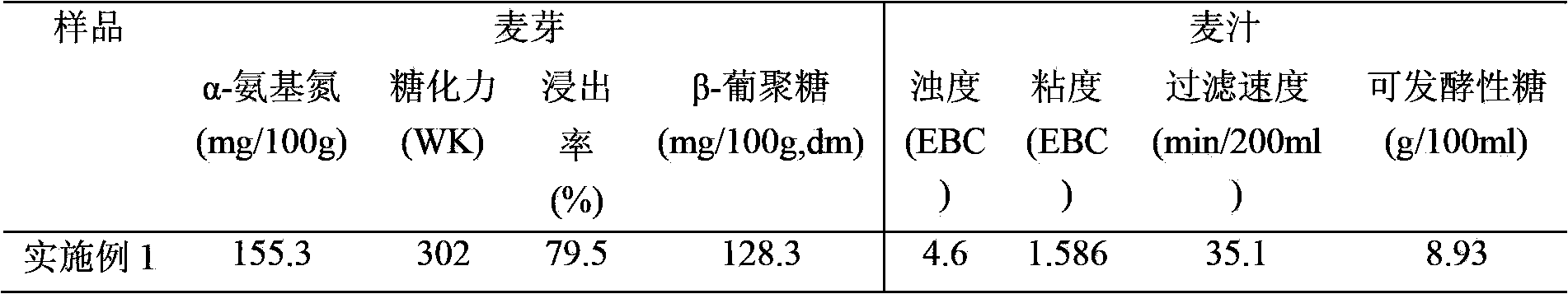

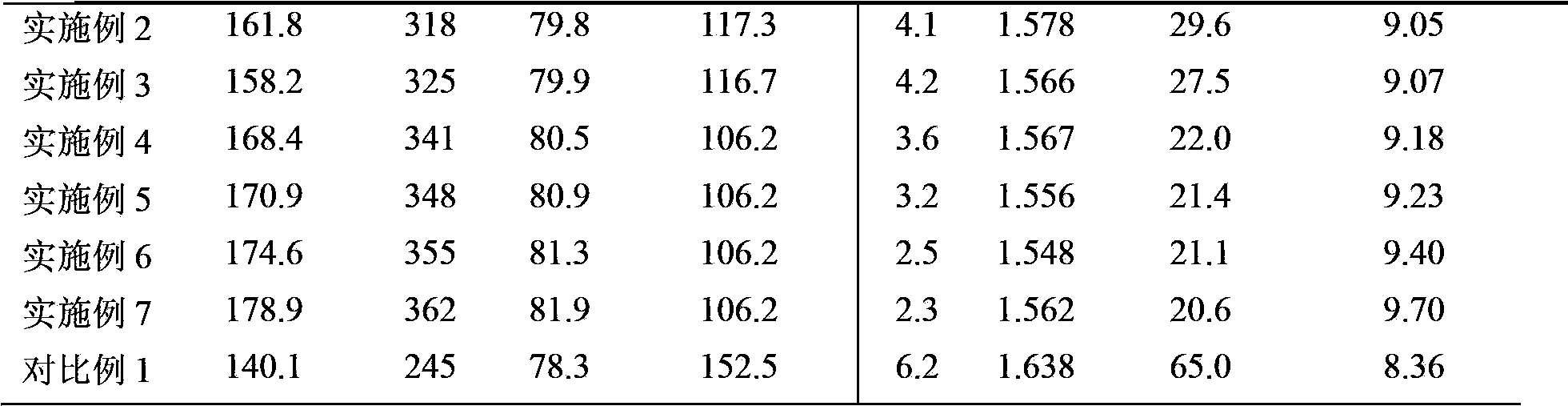

Examples

Embodiment 1

[0022] The domestic malt malt Supi No. 4 (provided by Jiangsu Jielong Malt Co., Ltd.) was used as the main raw material for the experimental operation. The process flow is: barley cleaning and impurity removal → soaking → adding malting additives (NaOH and Gibberella Sour)→germination→drying→root removal→finished malt→crushing→saccharification→filtering→boiling→adding hops→spinning→filtering→cooling.

[0023] The key steps are as follows:

[0024] The first step is to soak the wheat

[0025] The barley is sent to the husk treatment machine for pretreatment, and then the barley after husk is sent to the barley soaking tank and soaked in water. The method of soaking three times and breaking three times is carried out. The total soaking time is 14 hours, and the total water cut time is 16 hours. When immersing barley, control the temperature at 14°C and pass in compressed air at the same time; then release the water in the barley soaking tank to cut off the water from the barley...

Embodiment 2

[0038] The main raw material is Supi No. 4 (provided by Jiangsu Jielong Malt Co., Ltd.), which is domestically produced along the coast of Jiangsu. acid and NaCl)→germination→roasting→root removal→finished malt→crushing→saccharification→filtering→boiling→adding hops→spinning→filtering→cooling. The specific operation of its key steps is the same as that in Example 1, except that in the soaking step, except that NaOH with a total weight of 800 ppm of barley is added to the water for soaking wheat for the second time and NaOH with a total weight of barley of 0.1 ppm is added to water for soaking wheat for the third time. In addition to the ppm of gibberellic acid, 80ppm of the total weight of barley was added to the water for the third soaking of barley. Finally, the soaking degree and dew point rate of the barley reached 43.2% and 54% respectively.

Embodiment 3

[0040] The main raw material is Supi No. 4 (provided by Jiangsu Jielong Malt Co., Ltd.), which is domestically produced along the coast of Jiangsu. acid and CaCl 2 )→germination→roasting→root removal→finished malt→crushing→saccharification→filtering→boiling→adding hops→spinning→filtering→cooling. The specific operation of its key steps is the same as that in Example 1, except that in the soaking step, except that NaOH with a total weight of 800 ppm of barley is added to the water for soaking wheat for the second time and NaOH with a total weight of barley of 0.1 ppm is added to water for soaking wheat for the third time. In addition to the ppm of gibberellic acid, 50ppm of the total barley weight of CaCl was added to the water for the third soaking of barley 2 , finally making the barley soaking degree and dew point rate reach 44.1% and 56% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com