Olefin hydration reaction method

An alkene hydration and alkene technology, applied in organic chemistry, hydroxyl addition preparation, etc., can solve the problems of long residence time, affecting mass transfer reaction rate, low mutual solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

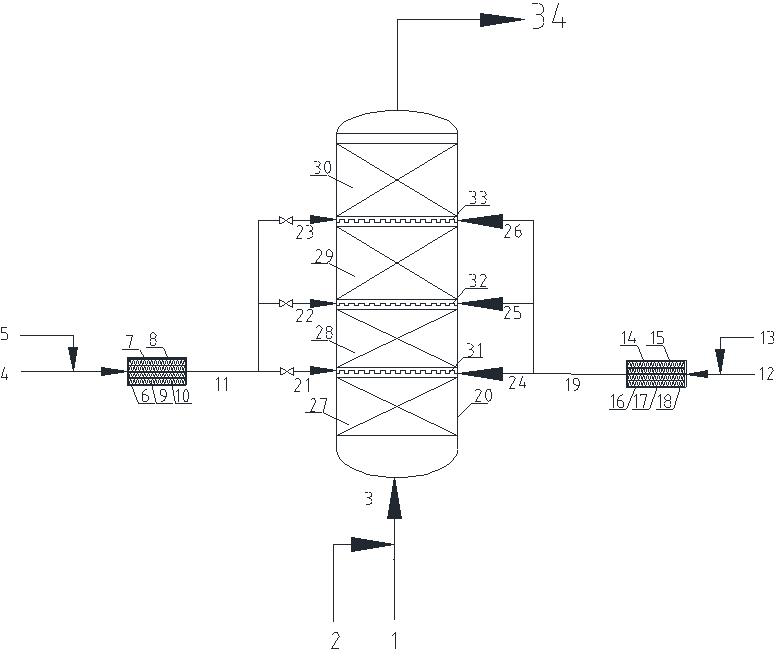

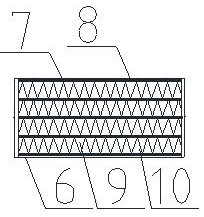

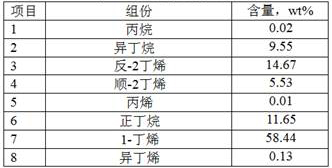

[0043] Using the n-butene in Table 1 as raw material, the hydration reaction of n-butene with water under the action of a catalyst was used to prepare sec-butanol. The olefin and water mixture material I is introduced into the n-butene hydration reactor from the bottom of the reactor, and the hydration reactor is provided with three-stage catalyst beds. The water olefin mass ratio is introduced into the microchannel mixing device I with a ratio of 5.0:1 to form feed II, and the water olefin mass ratio is introduced into the microchannel mixing device II with a ratio of 1:3 to form feed III, feed II and feed III At the same time, it is introduced between the first / second and second / third catalyst beds to enhance the mutual solubility of olefin / water phase, realize efficient mass transfer, improve the single-pass conversion rate of olefin hydration reaction, and reduce the ratio of water to olefin. The reaction effluent leaves the reactor and enters the next separation unit. Th...

Embodiment 2

[0047] In this embodiment, the reaction raw materials, reactor structure, and reaction process are the same as in Embodiment 1. The difference is that the mixed feed II and mixed feed III formed by the microchannel mixing device I in this embodiment are respectively introduced from the second and third catalyst beds. Among them, the operating conditions of the microchannel mixing device I are as follows: the temperature is 170° C., and the pressure is 7.2 MPaG; the operating conditions of the microchannel mixing device II are as follows: the temperature is 170° C., and the pressure is 7.2 MPaG. The reaction conditions, residence time and raw material conversion are shown in Table 3.

Embodiment 3

[0049] In this embodiment, the reaction raw materials, reactor structure, and reaction process are the same as in Embodiment 1. Different from Example 1, the present embodiment adopts more moderate reaction conditions, and the operating conditions of the microchannel mixing device I are as follows: the temperature is 148° C., and the pressure is 6.0 MPaG; the operating conditions of the microchannel mixing device II are as follows: temperature It is 148°C and the pressure is 6.0MPaG. The reaction conditions, residence time and raw material conversion are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com