Composite osmotic acid liquor and preparation method thereof

A technology of acid liquid and penetrating agent, which is applied in the field of compound penetrating acid liquid and its preparation, can solve the problems of high friction resistance and low permeability, etc., and achieve the effects of increasing service life, improving permeability performance, and increasing construction displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The content of thickener is 0.1%, the content of penetrating agent is 0.3%, the content of retarder is 1%, the content of corrosion inhibitor is 3%, the content of iron ion stabilizer is 1%, the content of demulsification and drainage aid is 1%, The HCl concentration of the hydrochloric acid solution used to prepare the composite osmotic acid solution of this embodiment is 15%.

Embodiment 2

[0059] The content of thickener is 0.1%, the content of penetrating agent is 1%, the content of retarder is 1%, the content of corrosion inhibitor is 3%, the content of iron ion stabilizer is 1%, the content of demulsification and drainage aid is 1%, The HCl concentration of the hydrochloric acid solution used to prepare the composite osmotic acid solution of this embodiment is 15%.

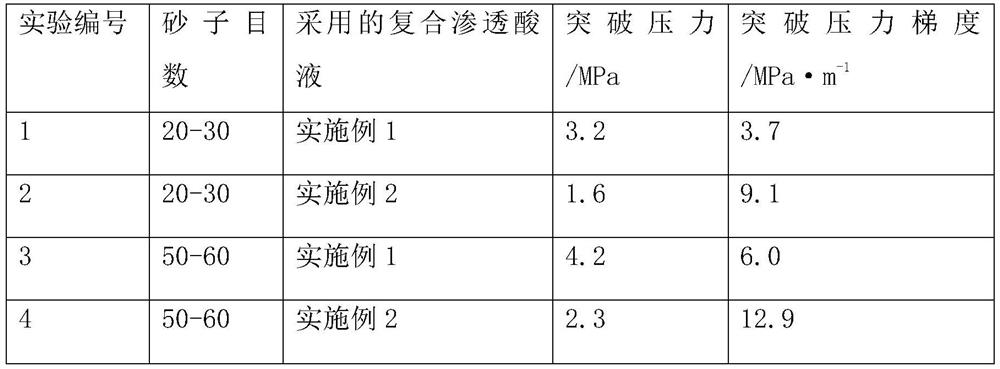

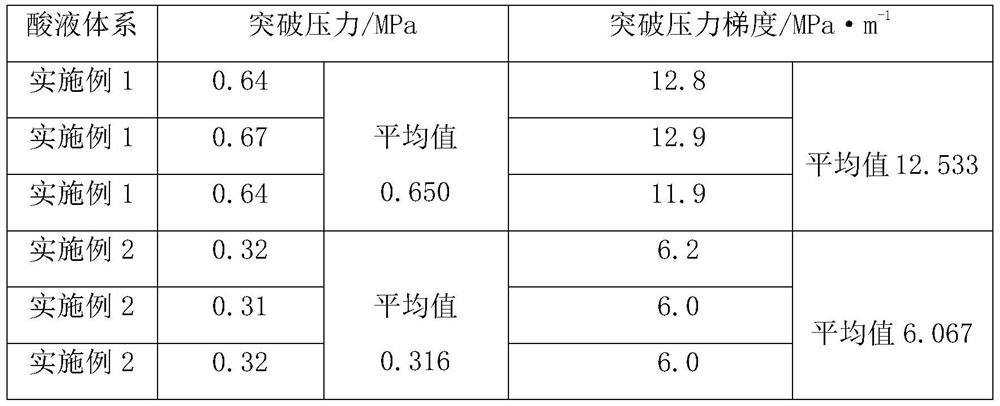

[0060] When the liquid permeates in one direction, the hydrophilic layer is more hydrophilic, and when the thickness is larger, the driving force is greater, and it tends to have one-way permeation performance, and the difference in osmotic pressure between the forward and reverse directions is large, and the permeation speed is fast. When the hydrophobicity of the hydrophobic layer is weak and the thickness is thin, the permeation resistance is small, which is beneficial to one-way permeation. The enlarged pore size makes one-way permeation easier and faster. Investigate the composite osmotic a...

Embodiment 3

[0081] The content of thickener is 0.15%; the content of retarder is 10%; the content of penetrant is 1%, the content of corrosion inhibitor is 3%; the content of iron ion stabilizer is 1%; The HCl concentration of the hydrochloric acid solution used to prepare the composite osmotic acid in this embodiment is 10%.

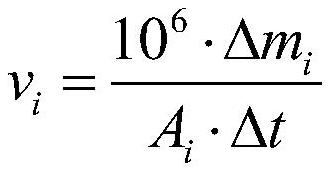

[0082] The sample of Example 3 and 3 test coupons were taken, and the indoor coupon experiment was carried out according to the requirement of reservoir temperature, which was 120°C in this embodiment. According to the oil and gas industry standard "SY / T 5405- 1996 Performance Test Methods and Evaluation Indexes of Corrosion Inhibitors for Acidification" evaluated the corrosion inhibition performance of the system. The corrosion rate is calculated according to the formula:

[0083]

[0084] In the formula: v i —Single piece corrosion rate, g / (m 2 h);

[0085] Δt—reaction time, h;

[0086] Δm 1 —corrosion vector of the slice, g;

[0087] A i —The surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com