Thin film capacitor element with middle heat dissipation through hole structure

A thin-film capacitor and heat dissipation through-hole technology, applied in thin-film/thick-film capacitors, electrical components, components of fixed capacitors, etc., can solve the problems of poor thermal conductivity of thin films, short circuit of plates, component burning, etc., and achieve working temperature rise. The effect of reducing, extending lifespan, and lowering corporate and social costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

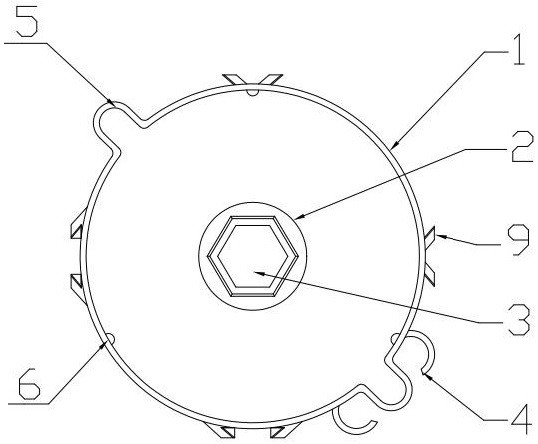

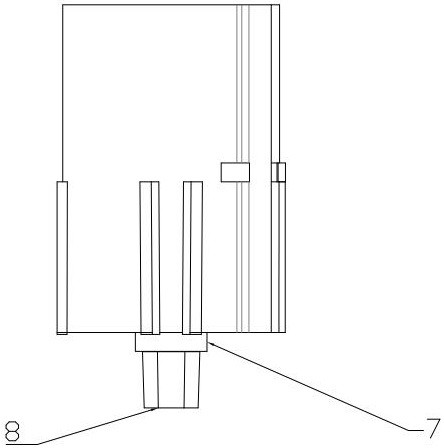

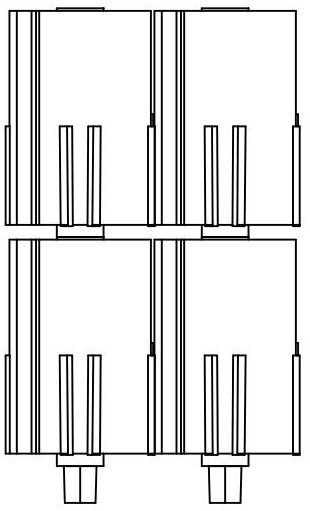

[0026] Such as figure 1 with figure 2 As shown, a thin film capacitor element with an intermediate heat dissipation through hole structure includes a capacitor core and a housing 1 for accommodating the capacitor core. The housing 1 is made of metal or non-metallic materials, rolled, cast, injection molded, Formed by 3D printing, machining, etc., its shape can be cylindrical, square prism or other forms with through-hole structures. The housing 1 is provided with a central through-hole 3, and the shape of the central through-hole 3 can be a circle. shape or any other shape, the mandrel through hole on the capacitor core is connected to the central through hole 3, so that part of the heat generated by the capacitor core is diffused through the central through hole 3, thereby reducing the actual working temperature inside the capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com