Vibration noise suppression method for bearingless switched reluctance motor

A switched reluctance motor, vibration and noise technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of lack of versatility and machinability, damage to the electrical characteristics of the motor, etc., to achieve strong engineering application value, suppress The effect of vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

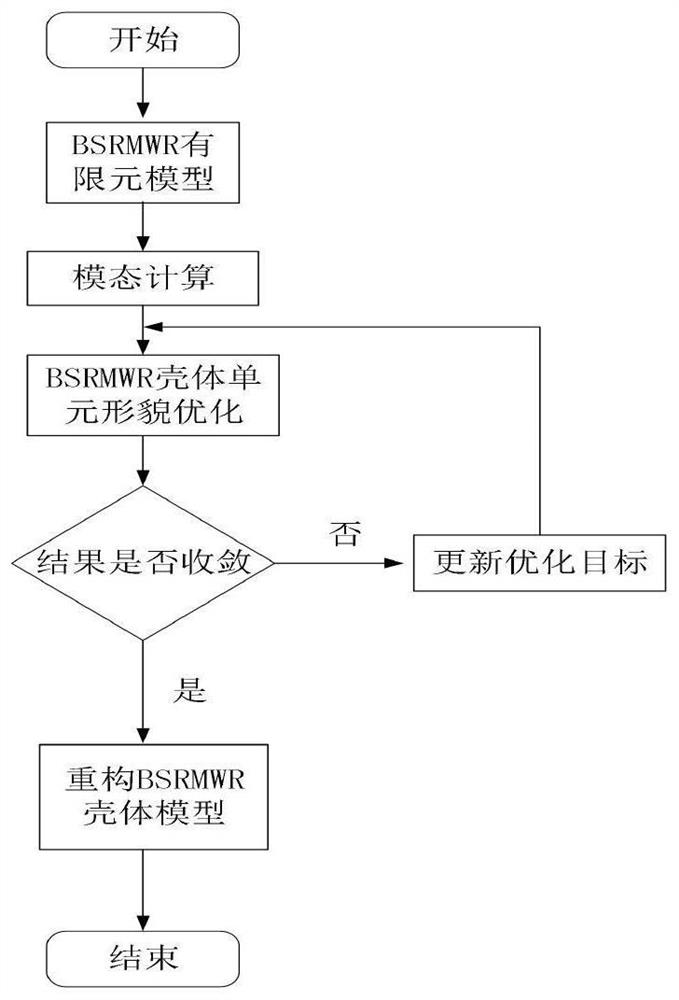

[0033] see figure 1 , the present embodiment provides a method of the present invention comprising the following steps:

[0034] S1. Establishment of motor model:

[0035] According to the main parameters of the 12 / 8-pole BSRMWR prototype, after the three-dimensional solid modeling of the motor is carried out in SolidWorks, it is imported into HyperWorks in x_t format or step format;

[0036] S2. Build the finite element model:

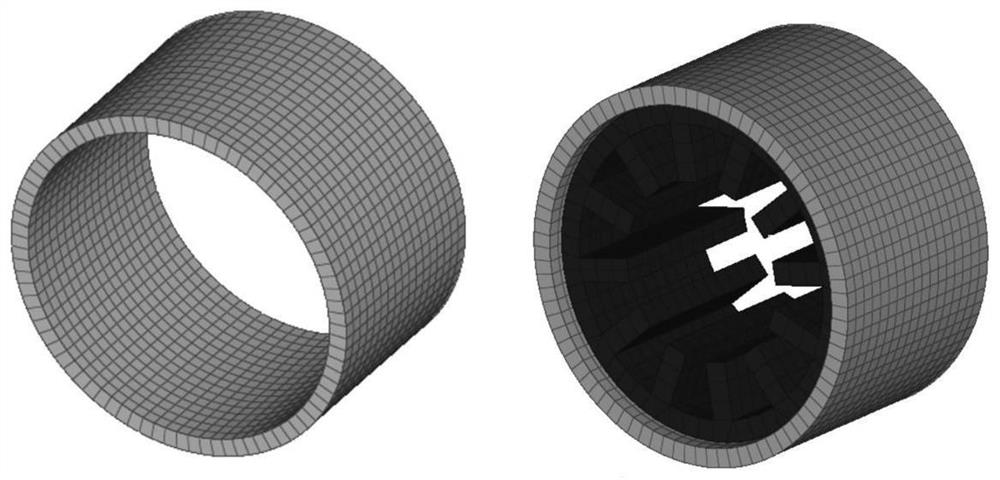

[0037] When the motor model is meshed, the stator adopts the solid element mesh, and the shell adopts the shell element mesh. The element mesh size is determined according to the geometric size and accuracy requirements of the motor; the material of the motor stator is steel, and the material of the shell is iron. Properties such as elastic modulus, Poisson's ratio, and density, established as figure 2 The modal analysis finite element model of the motor shown;

[0038] S3. Perform free mode calculation:

[0039] Perform free modal solution for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com