A preparation method of electrolytic machining array inclined hole cathode and array inclined hole cathode

An array electrode and cathode technology, which is applied in the field of preparation method and cathode structure of electrolytic machining tool cathode, can solve the problems of poor uniformity of flow field distribution of cathode liquid channel, poor insulation effect of cathode side wall, difficult preparation of cathode structure, etc. Improve the ability of anti-electrolyte erosion, reliable insulation performance, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

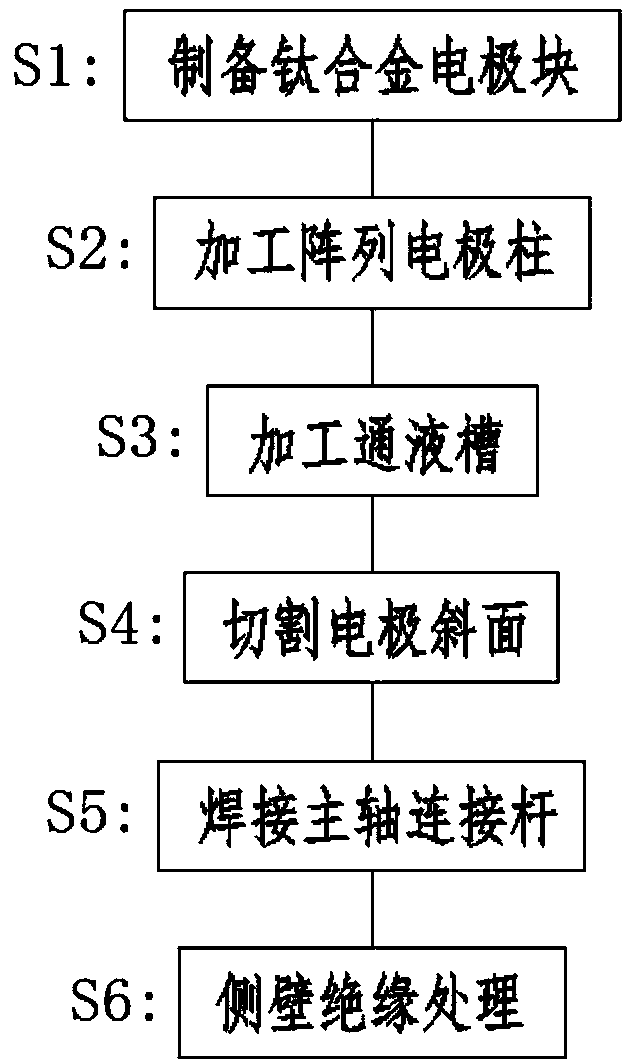

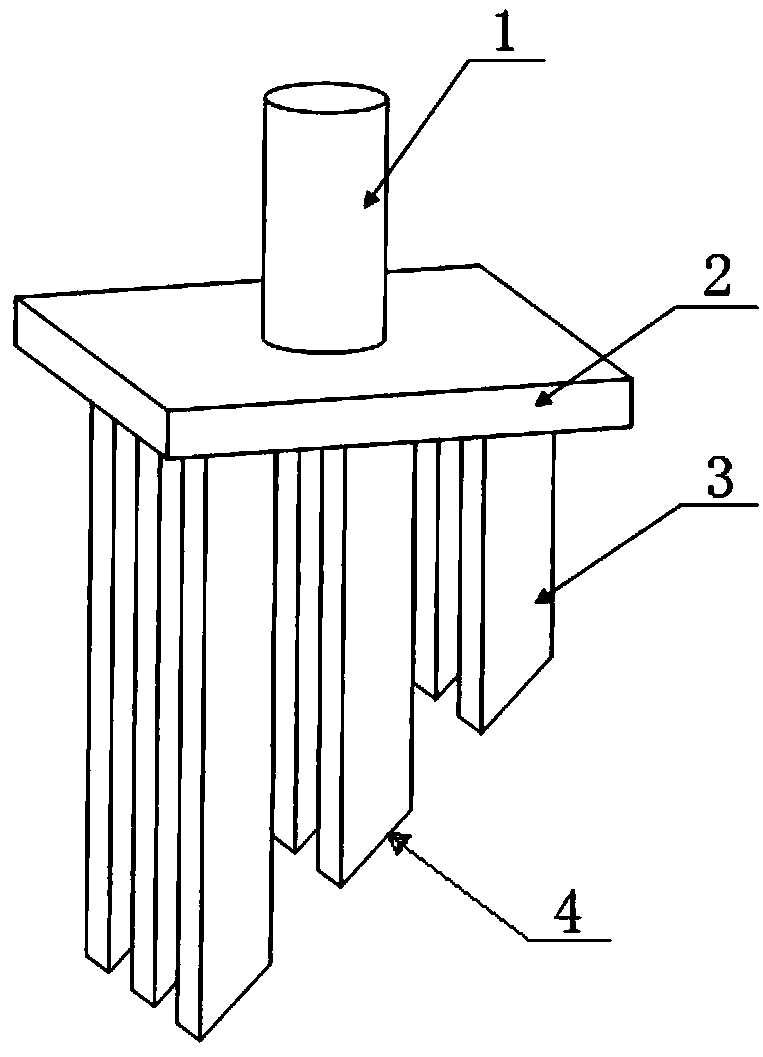

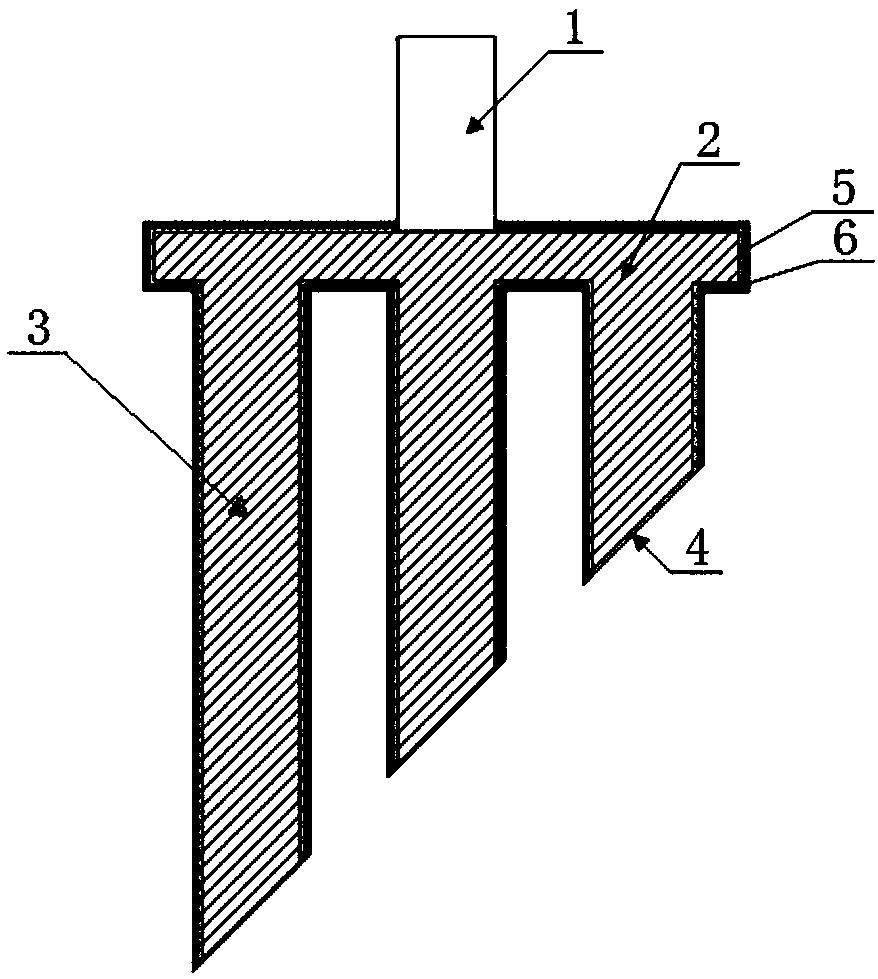

[0039] to combine figure 1 As shown, the preparation method of a kind of electrolytic machining array slanted hole cathode of this embodiment comprises the following steps:

[0040] S1. Preparation of titanium alloy electrode block: cutting each surface of titanium alloy square material by slow wire cutting process to obtain titanium alloy electrode block; before this step, in order to ensure higher cutting accuracy of titanium alloy electrode block, the titanium alloy square Put the material in the container of the ultrasonic equipment and add a water-based solvent to clean it for at least 30 minutes, take it out and dry it, and then perform slow wire cutting, which reduces the influence of dirt on the surface of the titanium alloy square material on the accuracy of wire cutting, so that the slow wire cutting can be used to obtain The parallelism between the top and bottom of the high-quality titanium alloy electrode block does not exceed 0.01mm, and the verticality between t...

Embodiment 2

[0048] A preparation method of the electrolytically processed array of inclined-hole cathodes and the array of inclined-hole cathodes in this embodiment, the preparation method and the basic structure of the array of inclined-hole cathodes are the same as in Example 1, the difference is that in the electrolytic processing of the array of inclined-hole cathodes In step S6 of the preparation method, first cover the electrode slope and the electrode power supply connection, then use micro-arc oxidation technology to insulate the electrode, and use electrophoresis technology to encapsulate the micro-arc oxidation insulating surface to form a double insulating composite layer; Carry out non-insulation protection on the electrode slope and the electrode power connection, and directly insulate other positions, and then remove the non-insulation protective layer on the electrode slope and the electrode power connection.

[0049] The preparation method of the electrolytic machining arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com