Test connection device for mass production test of fA-level current

A test connection and electrical connection technology, applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of inability to detect leakage current, deterioration of leakage current measurement accuracy, difficulty in meeting the requirements of mass production testing, etc. Measurement time, improving measurement accuracy, and reducing the effect of steady-state time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

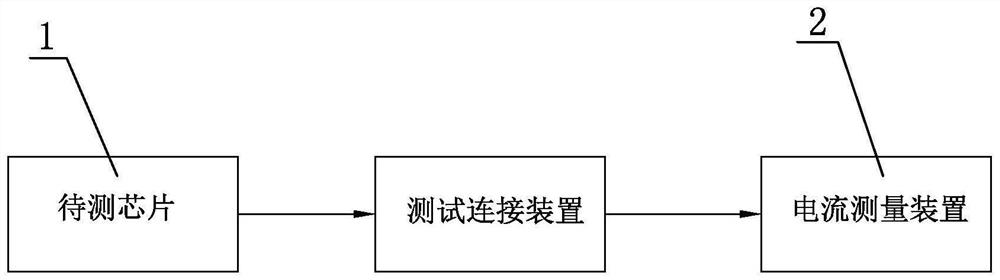

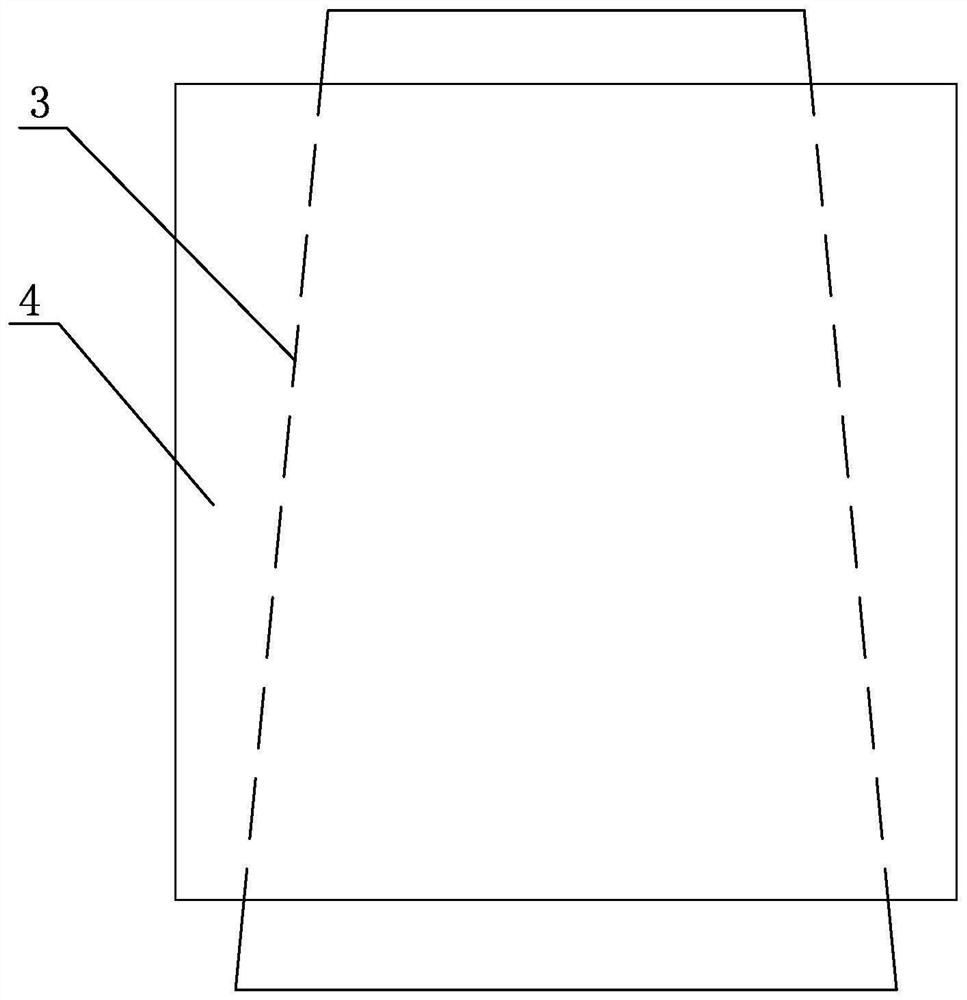

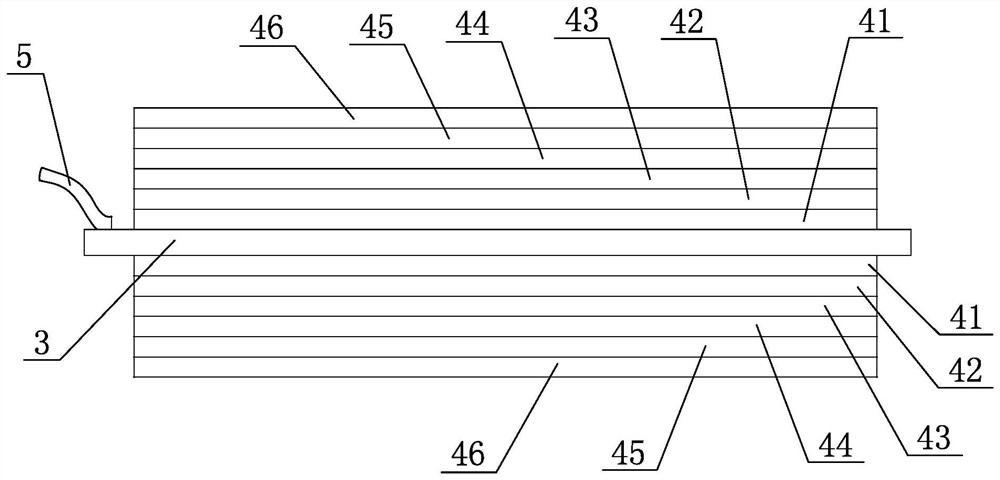

[0023] As shown in the figure, a test connection device for mass production testing fA level current is used to connect the chip 1 to be tested and the current measurement device 2. The chip 1 to be tested can be a commonly used chip such as an operational amplifier, and the current measurement device 2 It is an existing device, and the test connection device includes a test gold finger 3 and an electromagnetic shielding body 4 wrapped around the test gold finger 3. One end of the test gold finger 3 is electrically connected to the device terminal pin 5 of the chip 1 to be tested, and the test gold finger The other end of 3 is electrically connected to the current measuring device 2. The chip 1 to be tested generally has a plurality of device pins 5, and the number of test golden fingers 3 is generally equal to the number of device pins 5 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com