Detection equipment for dispensing nozzle

A technology for testing equipment and dispensing nozzles, which is used in the testing of mechanical equipment, mechanical components, and testing of machine/structural components. , quick installation, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

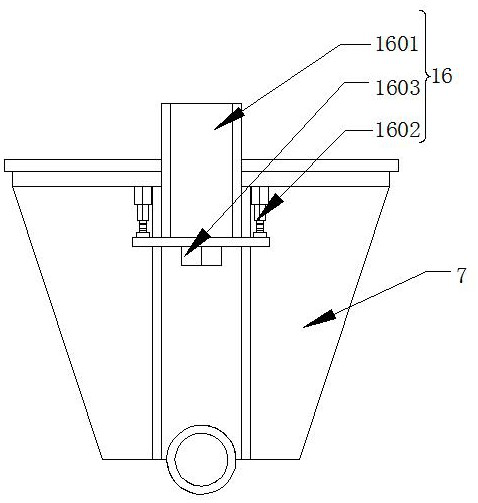

[0031] see Figure 1 to Figure 8, the present invention provides a technical solution: a detection device for dispensing nozzles, including a main body frame 1, a connecting cavity 2, a top cover 3, a connecting hole 4, a connecting pipe 5, a bellows 6, an auxiliary plate body 7, a servo motor 8, Visual inspection equipment 9, mounting plate 10, camera 11, connection base plate 12, base 13, adjustment assembly 14, external frame 1401, hydraulic cylinder 1402, internal frame 1403, motor 15, auxiliary assembly 16, connection hose 1601, electric pusher Rod 1602, limit plate 1603, auxiliary plate 17, first mounting groove 18, first connecting cavity 19, second mounting groove 20, second connecting cavity 21, third mounting groove 22, third connecting cavity 23, shaft body 24. Water pump 25, guide pipe 26, electric valve 27, collection frame 28, conveyor belt 29, baffle plate 30, work plate 31, auxiliary pipe 32, leak hole 33, hydraulic air rod 34, mounting seat 35, positioning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com