Thin-gauge Ni-free weathering steel produced based on CSP process and production method of thin-gauge Ni-free weathering steel

A production method and thin-gauge technology, applied in the field of iron and steel materials, can solve the problems of single use, no solution to copper brittle defects, etc., and achieve the effects of good cold-formability, good atmospheric corrosion resistance, and reduced manufacturing costs.

Pending Publication Date: 2022-05-13

MAANSHAN IRON & STEEL CO LTD

View PDF19 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although Ni was not added, no measures were proposed to solve copper brittle defects at high Cu content

And it is only used for container manufacturing, with a single purpose

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 6

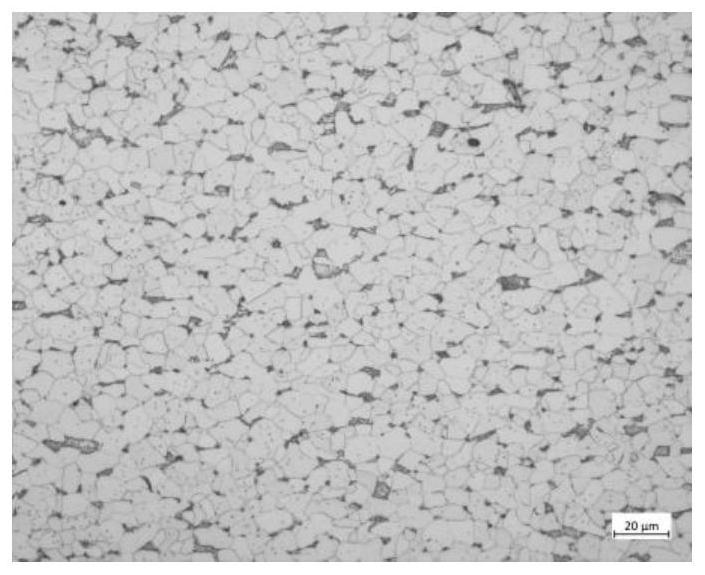

[0038] A thin-gauge Ni-free weathering steel produced based on the CSP process, including the following mass percentage components: as shown in Table 1, the balance not shown in Table 1 is Fe and unavoidable impurities. The weather resistance index of each embodiment is I≥7.0, which has excellent atmospheric corrosion resistance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

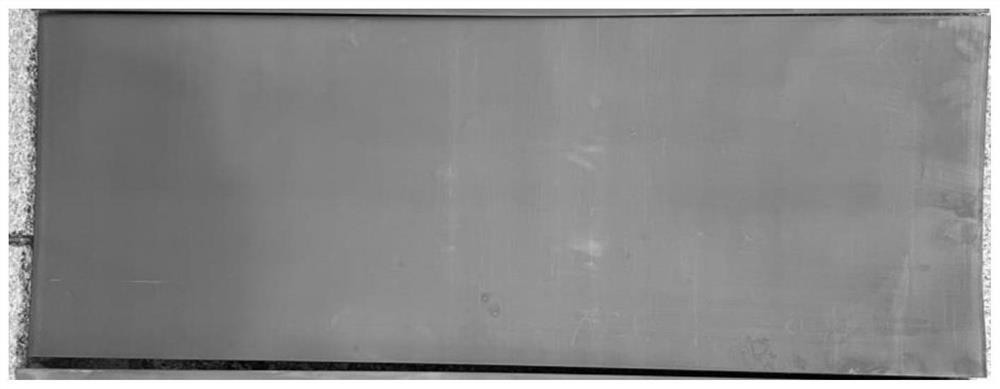

The invention provides thin-gauge Ni-free weathering steel produced based on a CSP process and a production method of the thin-gauge Ni-free weathering steel. The thin-gauge Ni-free weathering steel comprises the following components: 0.04%-0.06% of C, 0.30%-0.55% of Si, 0.30%-0.80% of Mn, 0.020%-0.150% of P, less than or equal to 0.005% of S, 0.30%-0.80% of Cr, 0.25%-0.40% of Cu, 0.015%-0.040% of Als, 0.010%-0.040% of Ti and the balance of Fe and inevitable impurity elements. A proper amount of P and Si are added, through matching design and interaction of Si-P-Cu-Cr elements, the problems of continuous casting bleed-out and product surface crack defects caused by copper brittleness are solved, the manufacturing cost is reduced, and meanwhile good atmospheric corrosion resistance and strong plasticity matching are achieved.

Description

technical field [0001] The invention belongs to the field of iron and steel materials, and in particular relates to a thin gauge Ni-free weathering steel produced based on a CSP process and a production method thereof. Background technique [0002] Weathering steel, also known as atmospheric corrosion-resistant steel, has less alloy content than stainless steel and lower manufacturing costs. Compared with ordinary carbon steel, it has good atmospheric corrosion resistance and is widely used in railway vehicles, containers, buildings, photovoltaic brackets and other industries. Cu can significantly improve the atmospheric corrosion resistance of steel. It is one of the main alloying elements added to weathering steel. However, its melting point is only 1083°C. Due to the existence of Cu, it is easy to cause breakout, billet heating and thermal Surface quality defects such as edge cracks occur during the rolling process. In the past, Cu and Ni were often added together in wea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/20C22C38/06C22C38/28C21D8/02

CPCC22C38/02C22C38/04C22C38/002C22C38/20C22C38/06C22C38/28C21D8/0226C21D2211/005C21D2211/009

Inventor 何博胡学文郭锐汪飞石践王海波张宇光赵海山王飞舒宏富鲍磊李耀辉史红林饶添荣

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com