Preparation method of graphite negative electrode material as well as product and application of graphite negative electrode material

A graphite negative electrode and graphite technology, applied in the direction of negative electrodes, chemical instruments and methods, battery electrodes, etc., can solve the problems of capacity attenuation, intensified side reactions, and serious polarization of negative electrodes, and achieve lower OI value, long cycle life, and reduced or defect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

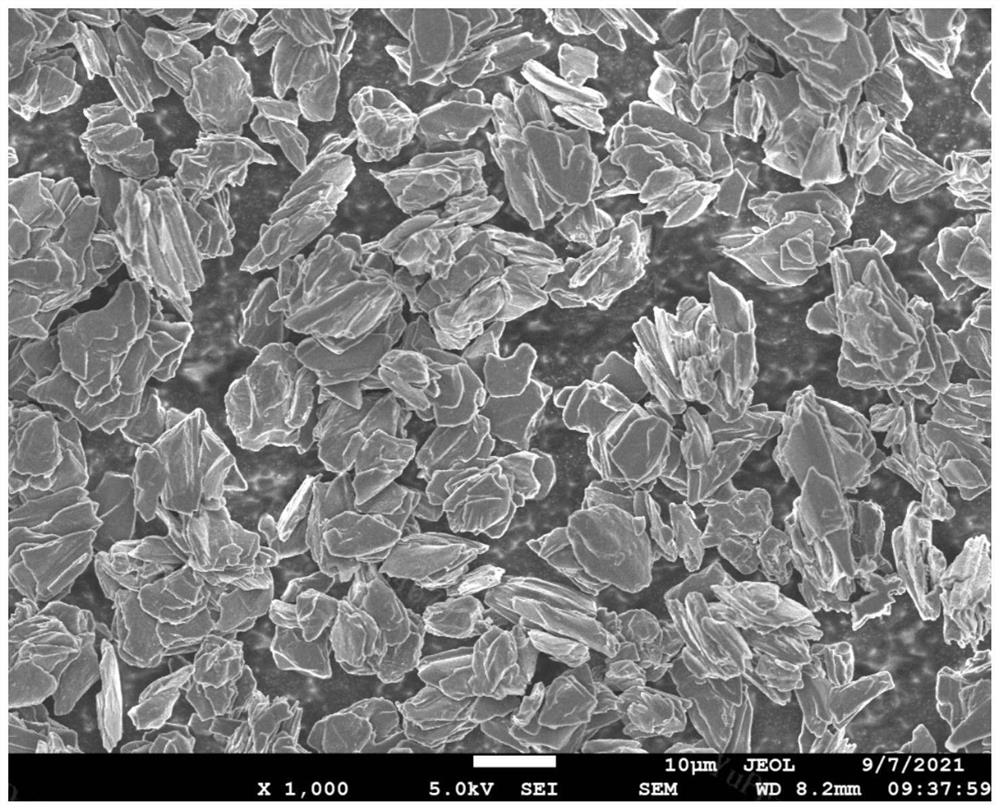

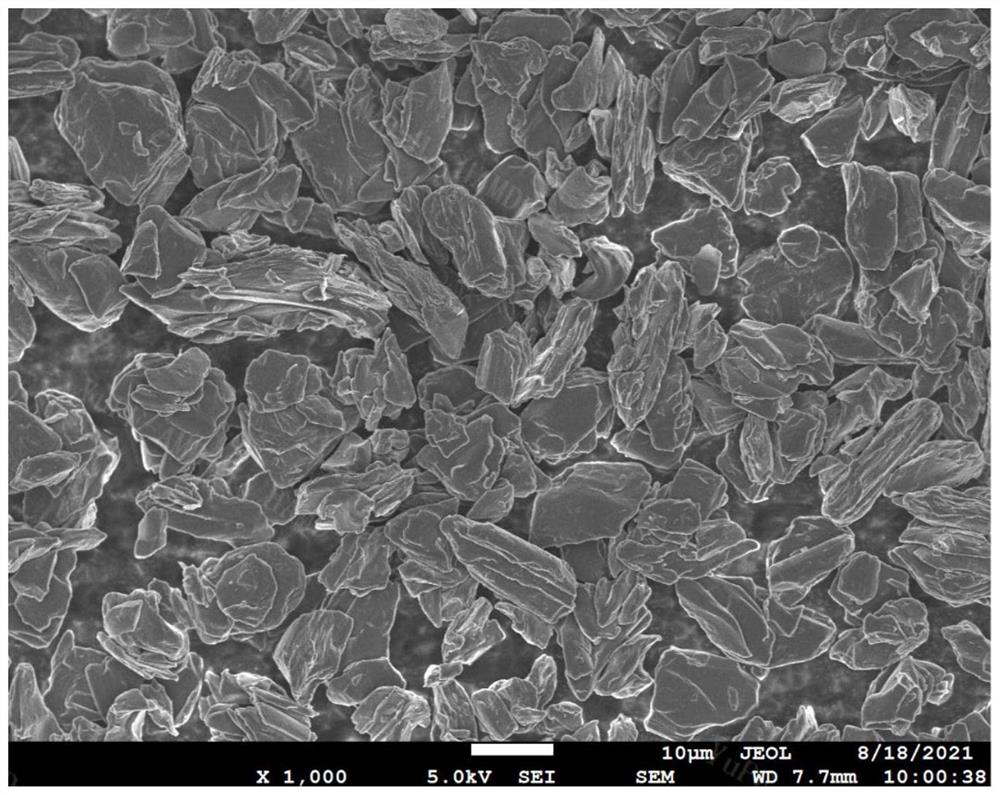

Image

Examples

preparation example Construction

[0025] The first aspect of the present invention aims to provide a preparation method of graphite negative electrode material, comprising the following steps:

[0026] S1. Choose graphite raw material with D50 of 5-9μm, mix it with oily organic matter, then raise the temperature to 300-400°C at a rate of 2-4°C / min, keep it warm for 70-100min, and then heat it at 2-4°C Raise the temperature at a rate of 620-650°C at a rate of 1 / min, and keep it warm for 60-90 minutes to obtain the coated graphitized precursor;

[0027] S2. Graphitizing the graphitized precursor obtained in step S1 at 2800-3000° C. for 40-55 hours in an inert atmosphere to obtain a graphitized product;

[0028] S3, mixing and granulating the graphitized product obtained in step S2 with pitch to obtain secondary granules;

[0029] S4. Carbonize the secondary particles obtained in step S3 at 1050-1150° C., and then sieve to obtain the graphite negative electrode material.

[0030] Among them, the preparation met...

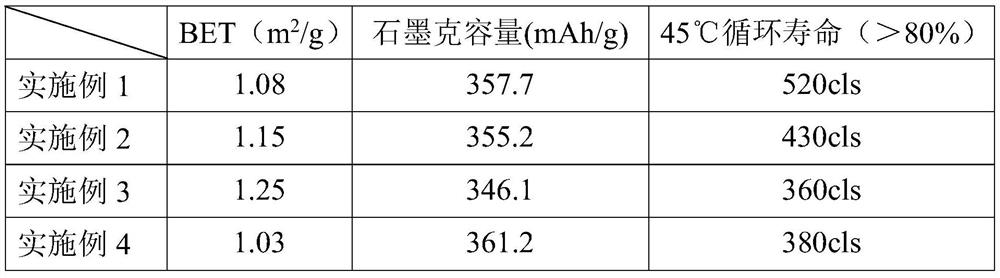

Embodiment 1

[0050] A preparation method of graphite negative electrode material, comprising the following steps:

[0051] S1. After crushing, grinding and grading the needle-shaped forged coke, obtain graphite raw material with a D50 of 6-8 μm, stir and mix it with coal tar in a horizontal reactor, and the weight of coal tar is 8% of the weight of graphite raw material. %, then at a stirring rate of 15Hz, the temperature was raised to 350°C at a rate of 2-4°C / min, and kept at a temperature of 70-100 minutes, and then the temperature was raised to 640°C at a rate of 2-4°C / min, and held at a rate of 60-90 minutes. obtain the coated graphitized precursor;

[0052] S2. Sieve the graphitized precursor, then put it into a graphite crucible for graphitization treatment, and treat it at 3000° C. for 48 hours in an inert atmosphere to obtain a graphitized product;

[0053] S3. Mix and granulate the obtained graphitized product and low-temperature pitch. The weight of the pitch is 15% of the weigh...

Embodiment 2

[0056] The difference from Example 1 is step S1, the weight of coal tar added in this embodiment is 15% of the weight of graphite raw material.

[0057] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com