Variable excitation brushless alternating-current generator

An alternator, electrical connection technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as poor low-speed charging performance, and achieve the effects of improved charging performance, good charging performance, and high magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

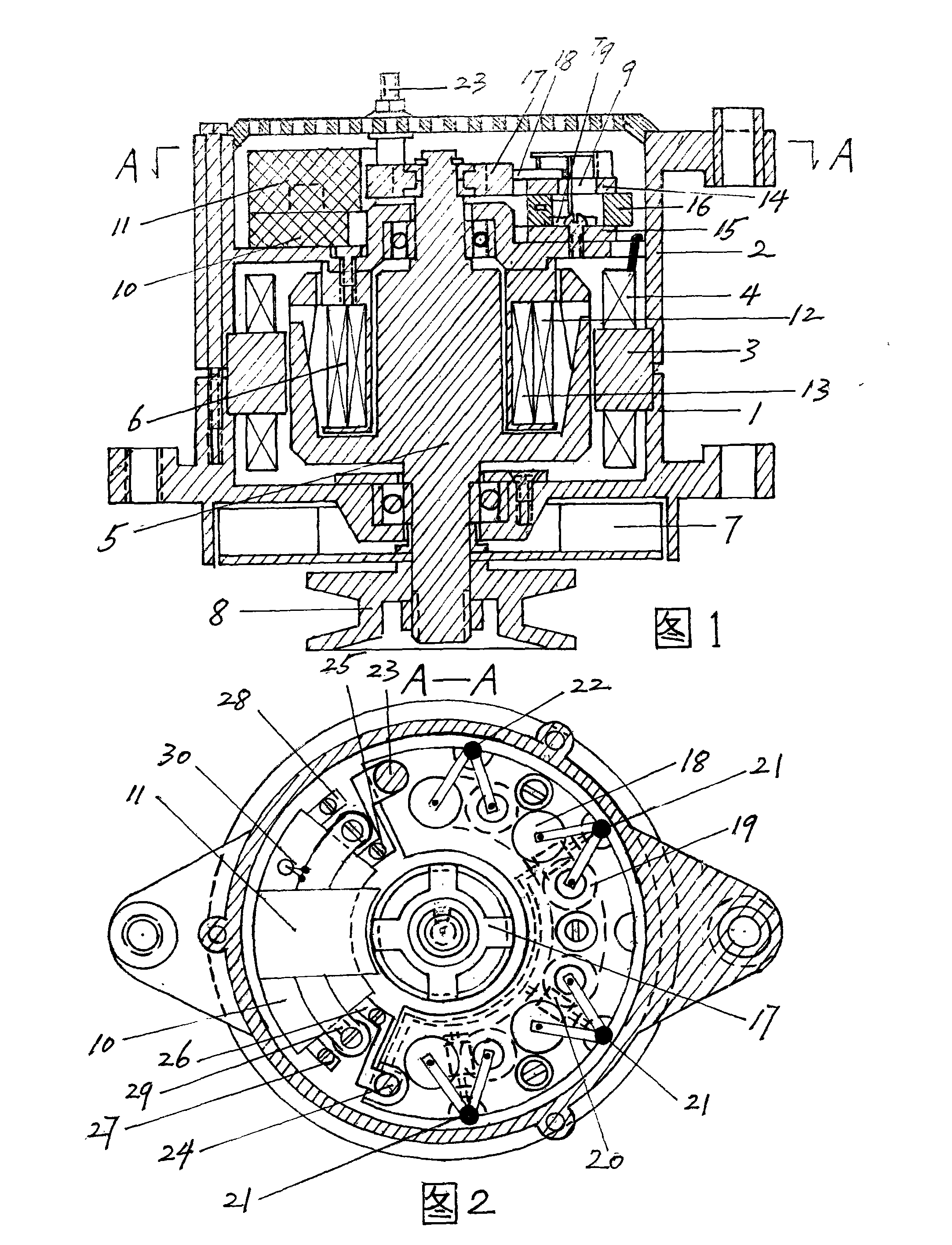

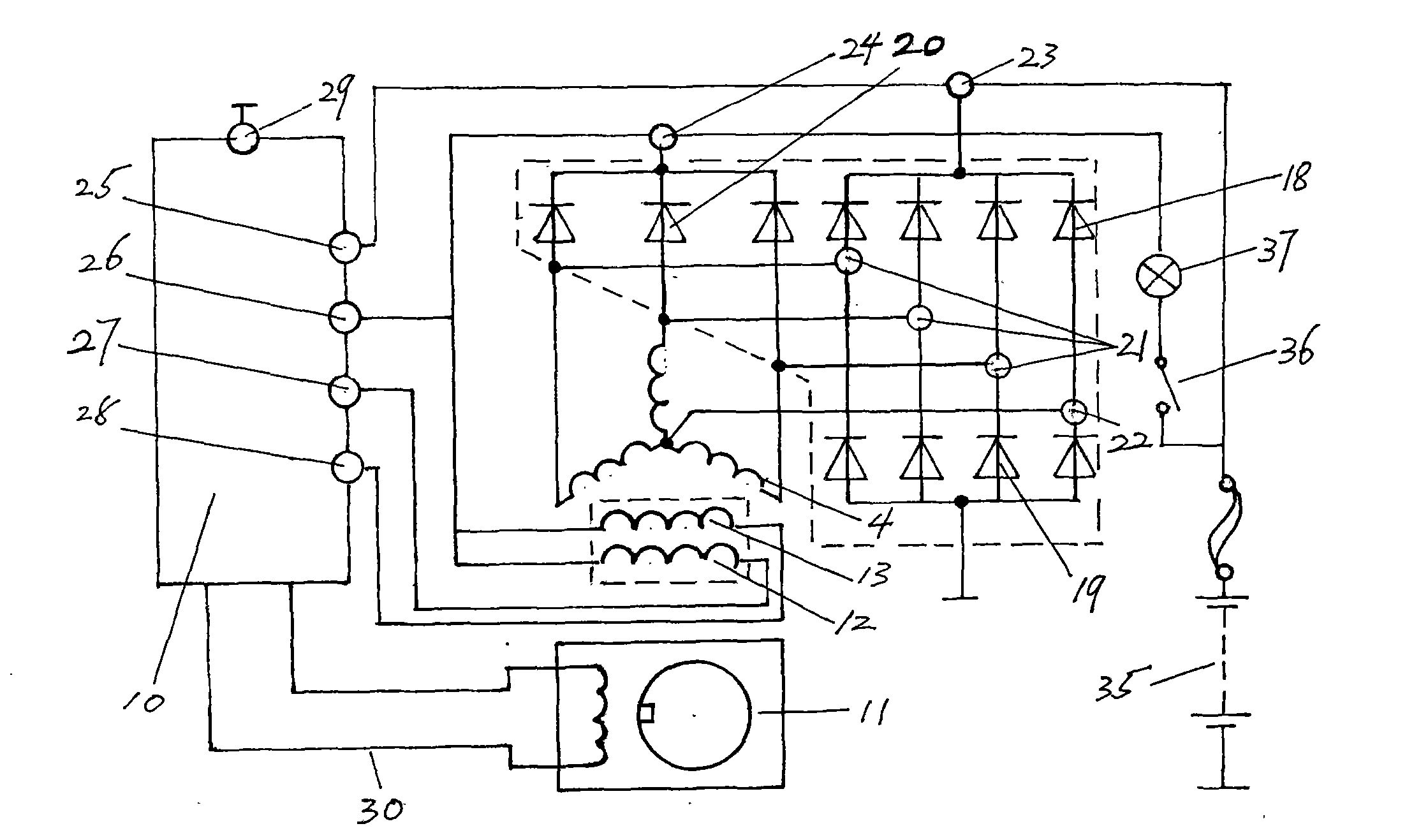

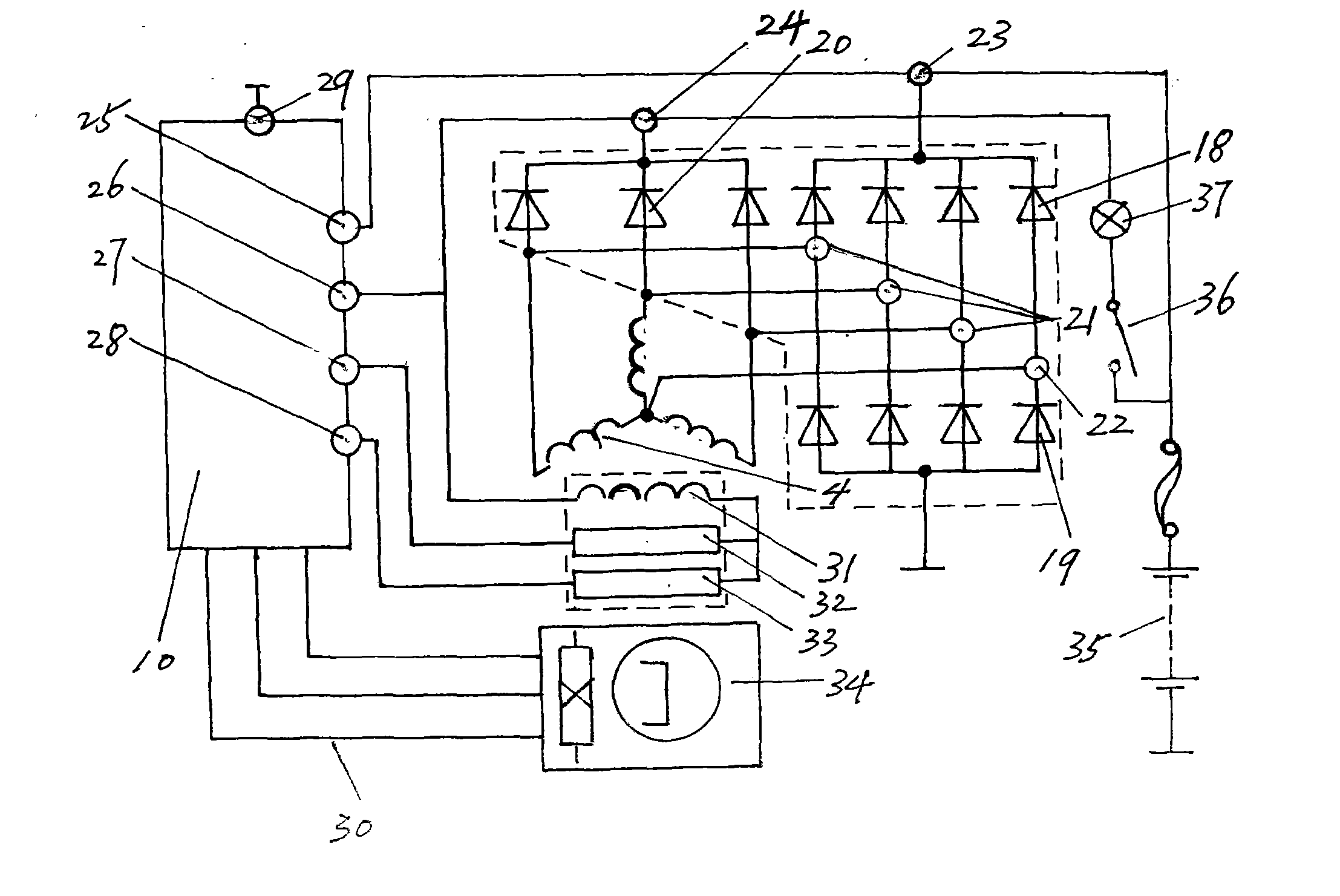

[0012] exist figure 1 The shown variable excitation brushless alternator is mainly composed of a front end cover 1, a rear end cover 2, a stator assembly composed of a stator assembly core 3 and a stator three-phase winding 4, a rotor assembly composed of a rotor 5 and a double excitation winding 6 Cheng, fan 7, belt pulley disc 8, rectifier 9, transformer and voltage regulator 10, electromagnetic generator speed sensor 11. The stator assembly consisting of the iron core 3 of the stator assembly and the stator three-phase winding 4 covers the front end cover 1 with the front end cover 1 and the rear end cover 2 with bolts, and is composed of the rotor 5 and the double excitation winding 6 The rotor assembly is assembled in the front end cover 1 and the rear end cover 2 and the inner ring of the iron core 3 of the stator assembly. The front end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com