Grinding transfer device

A transfer device and grinding technology, applied in transportation and packaging, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of conveyor belt workpiece transfer, large safety hazards, etc., to reduce safety Hidden dangers, improving ride comfort, and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

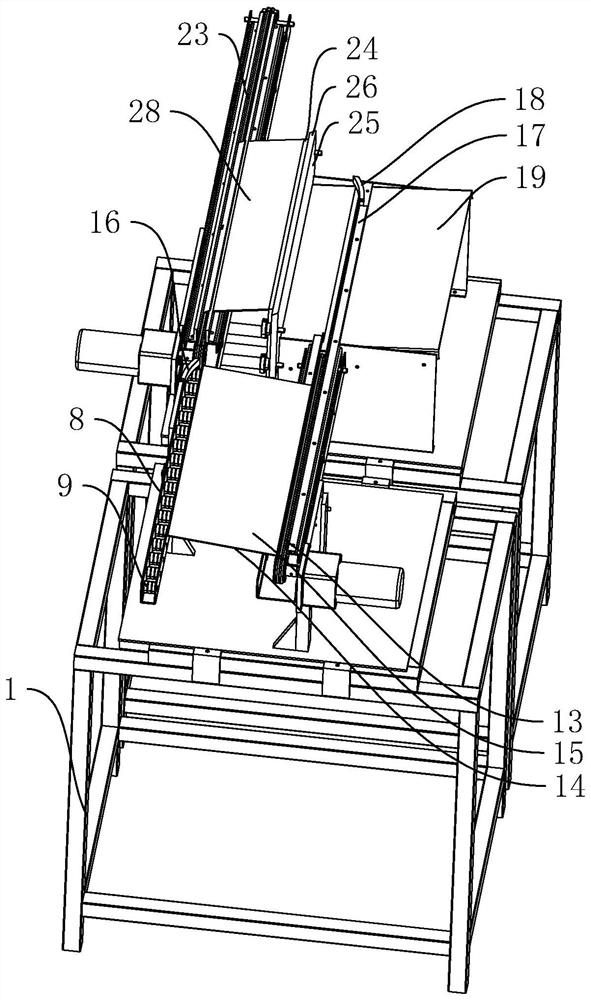

[0046] The application will be described in further detail below in conjunction with the accompanying drawings.

[0047] The embodiment of the present application discloses a grinding transfer device.

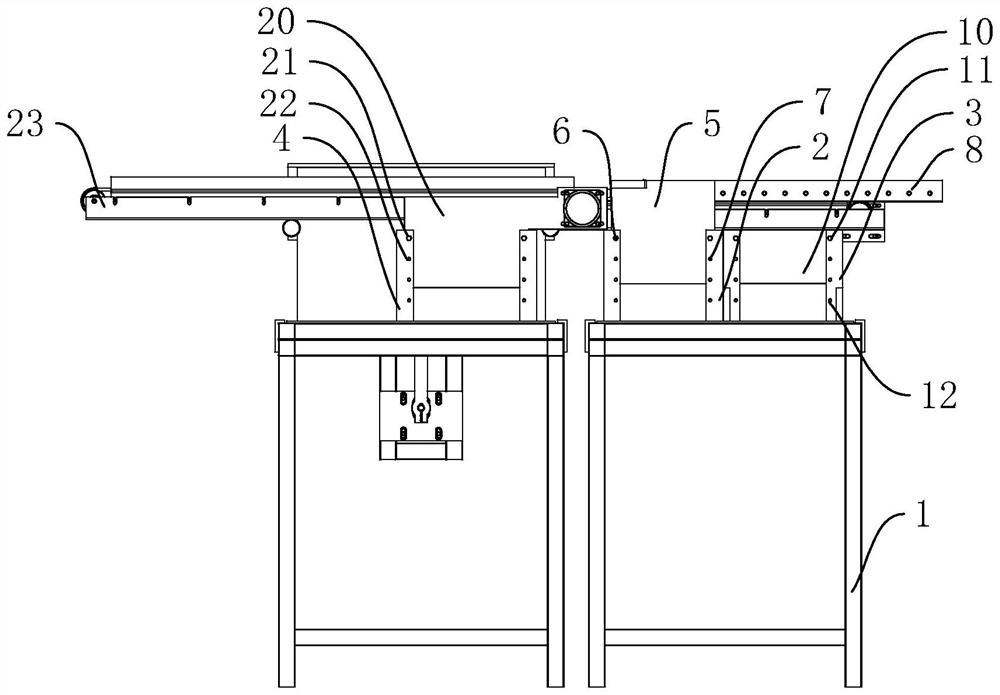

[0048] refer to figure 1 , including a base 1 , the upper end of the base 1 is fixedly connected with a first adjusting frame 2 , a second adjusting frame 3 and a third adjusting frame 4 .

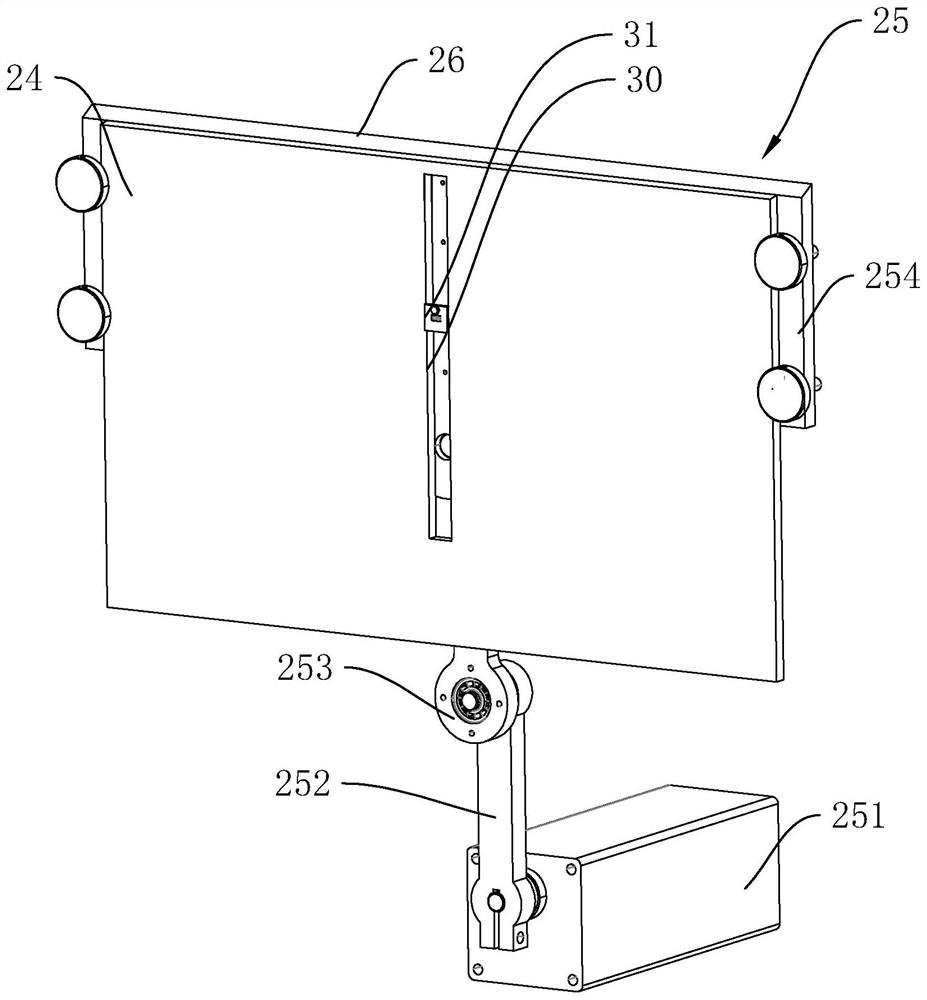

[0049] refer to figure 1 with figure 2 , the first adjusting frame 2 is connected with a first mounting plate 5, the first mounting plate 5 is pierced with a first adjusting bolt 6, and the first adjusting frame 2 is provided with a first adjusting screw hole 7 for threaded connection of the first adjusting bolt 6 , the first mounting plate 5 is fixedly connected to the first adjusting frame 2 through the cooperation of the first adjusting bolt 6 and the first adjusting screw hole 7 . The first adjusting screw holes 7 are provided with a plurality of first adjusting screw holes 7 in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com