Aluminum bar transferring device

A technology of transfer device and aluminum rod, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of saving operation and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

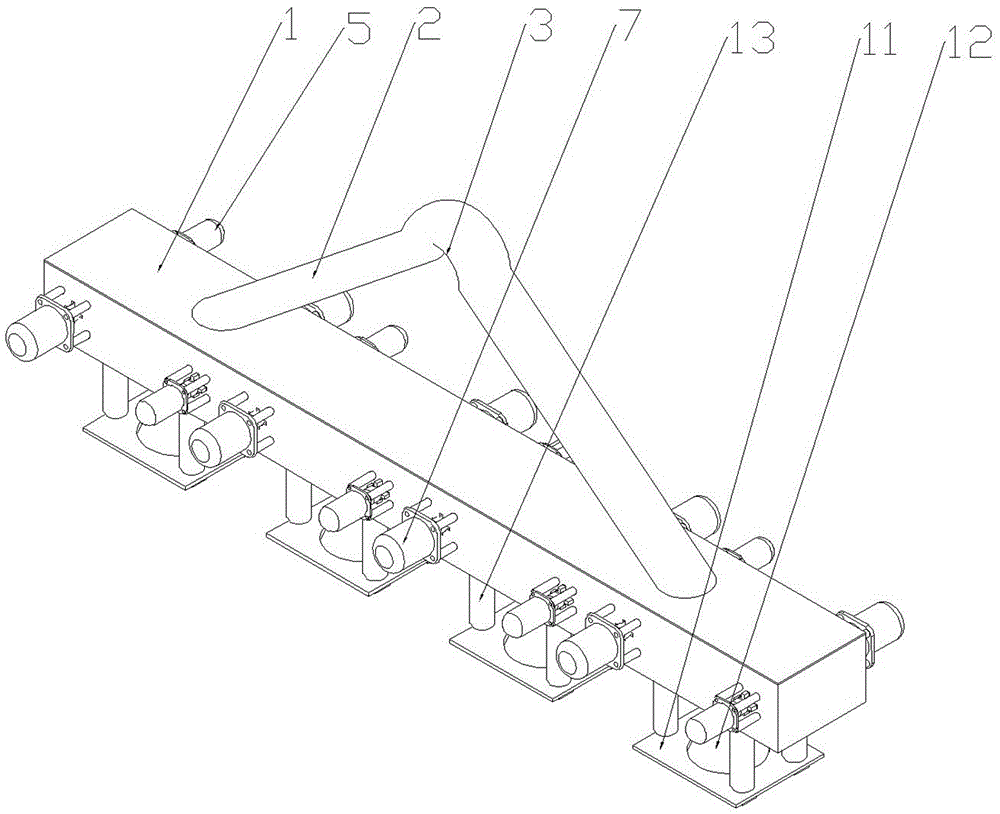

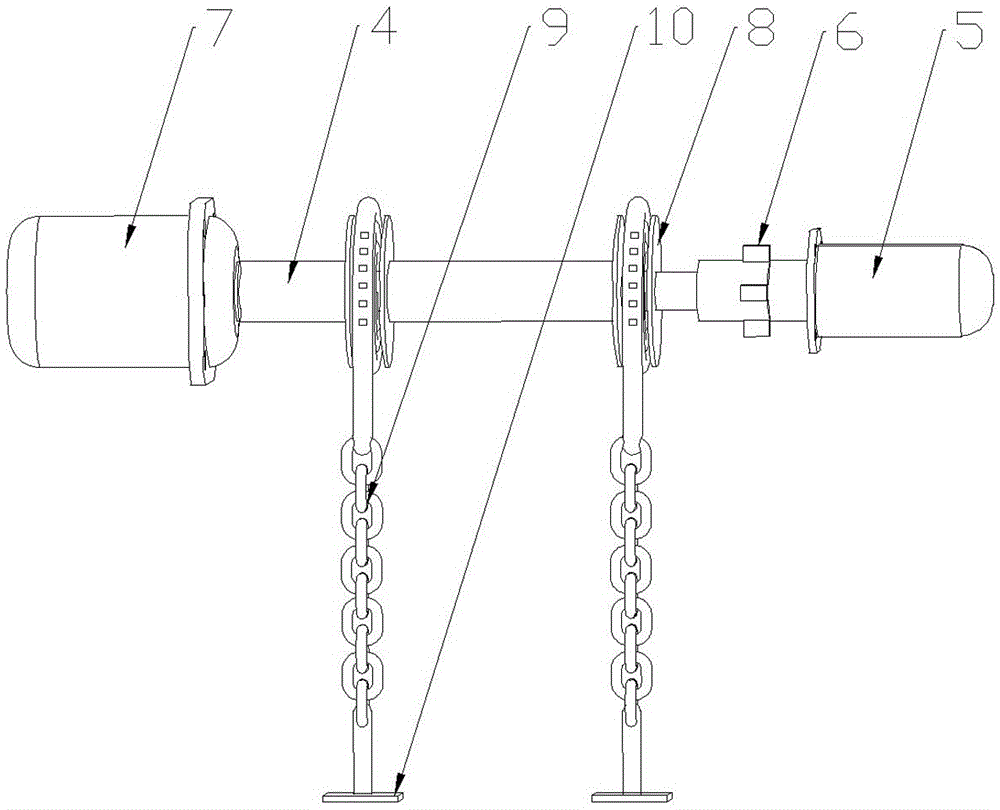

[0015] The reference signs in the drawings of the description include: transfer beam 1, lifting lug 2, arc section 3, rotating shaft 4, hydraulic column 5, cross block 6, motor 7, chain disc 8, chain 9, clip bar 10, sleeve Plate 11, round hole 12, cylinder 13.

[0016] Such as figure 1 with figure 2 Shown: An aluminum rod transfer device, including a transfer beam 1, the transfer beam 1 is provided with a lifting lug 2 for driving hooks, the transfer beam 1 is provided with a spare lifting lug 2, and the lifting lug 2 is provided with an arc section 3. The transfer beam 1 is provided with a through groove in the length direction, and the transfer beam 1 is provided with several rotating shafts 4 arranged in parallel in the width direction. The transfer beam 1 welds bearings for the rotating shaft 4 to pass through on both sides of the groove. The two ends of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com