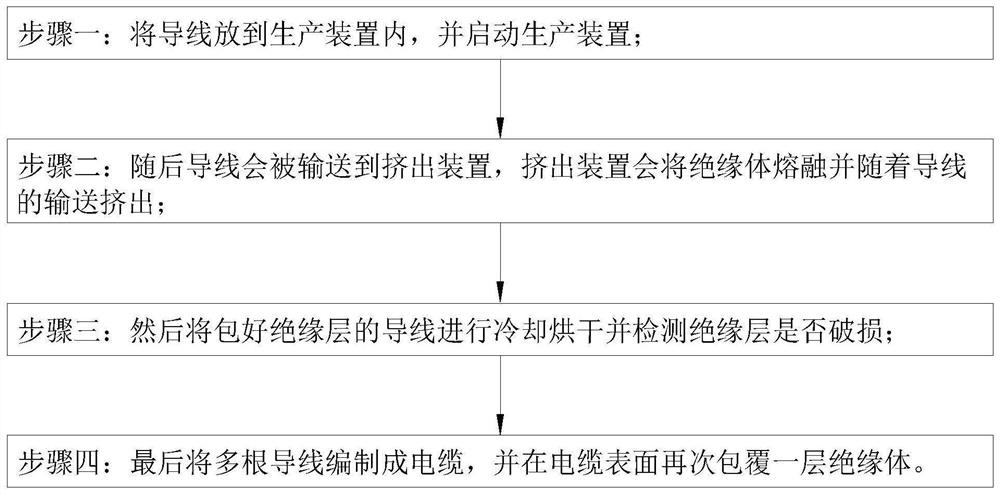

High-resistance flame-retardant PVC cable production device and use method

A production device and high-resistance technology, applied in the field of flame-retardant cable production, can solve problems such as wire leakage, accumulation of molten insulators, and influence on the quality of production wires, and achieve the effect of reducing workload and avoiding uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

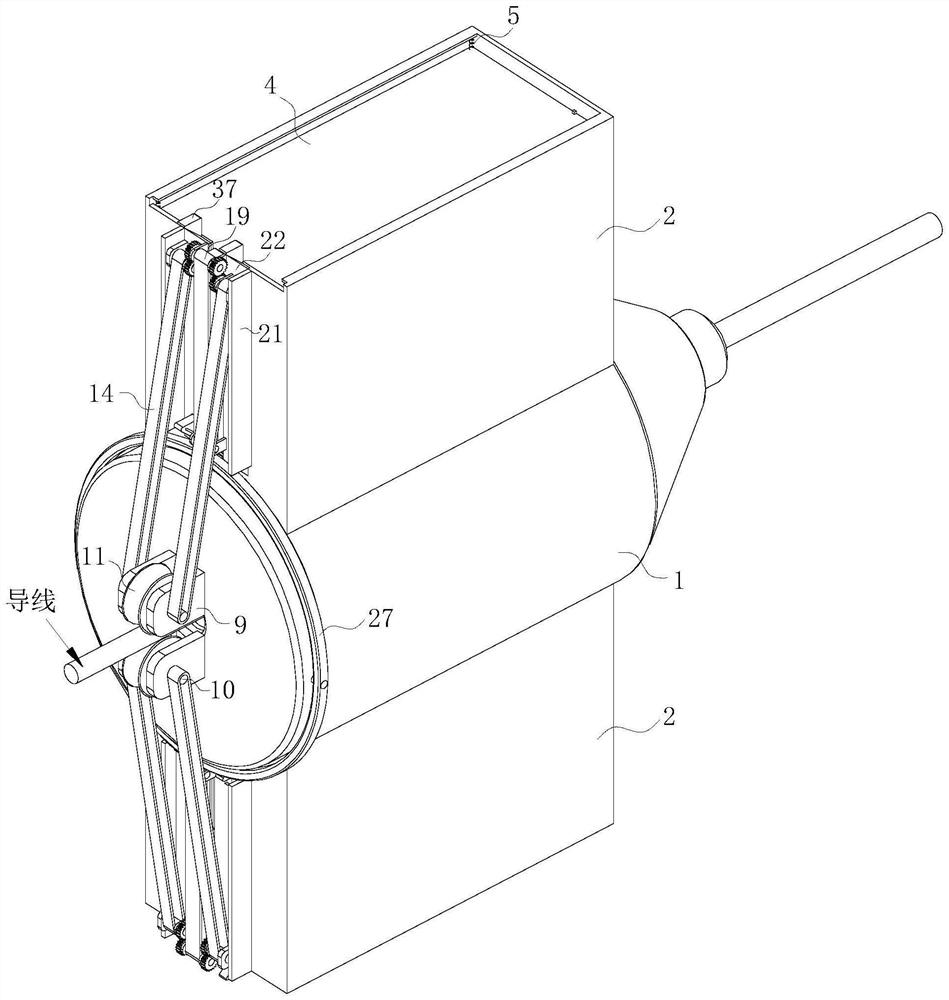

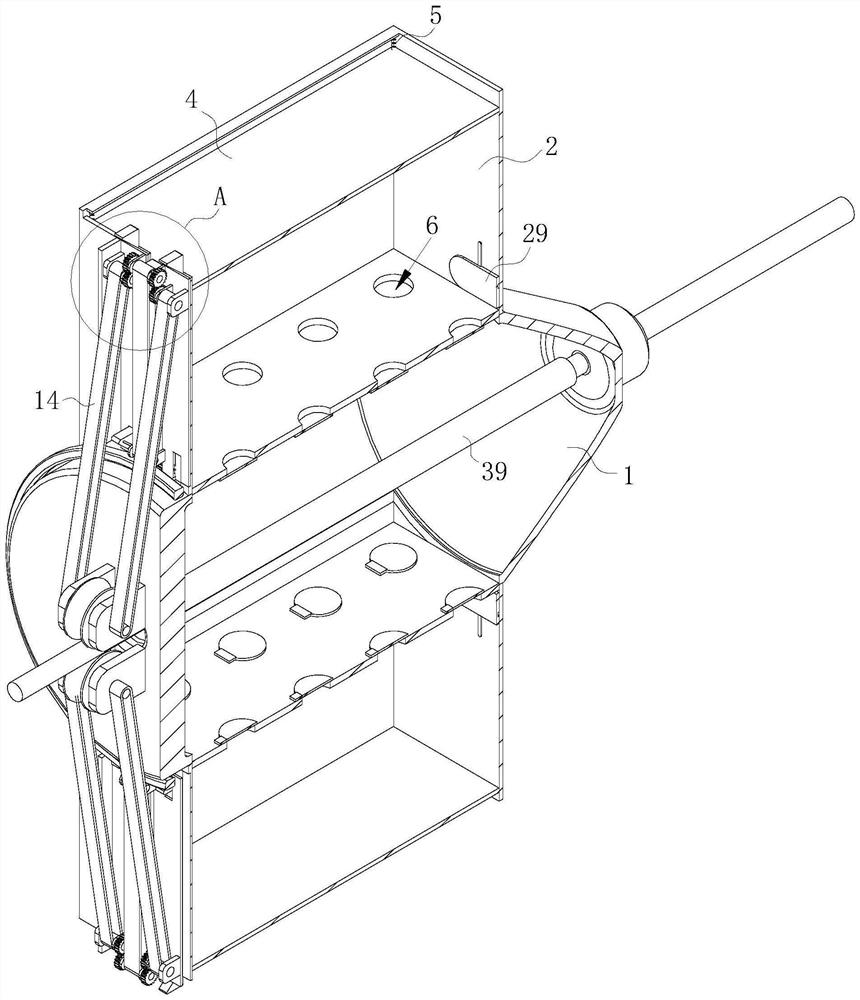

[0040] see Figure 1-16 , the present invention provides a technical solution: a high-resistance flame-retardant PVC cable production device, including an extrusion cylinder 1, the right end of the extrusion cylinder 1 is the extrusion end and the right end of the extrusion cylinder 1 is tapered, and the extrusion cylinder 1 The upper and lower ends of the two storage boxes 2 are connected with the storage box 2, the upper end of the storage box 2 is open, the right side of the two storage boxes 2 is connected with the adding pipe 3, and the left side of the two storage boxes 2 is equipped with an extrusion mechanism , the extrusion mechanism can adjust the extrusion speed of the molten insulator according to the wire conveying speed, and a switching mechanism is provided between the two extrusion mechanisms, and the switching mechanism is used to perform the process after the molten insulator in the single material storage box 2 is completely extruded. Switch another extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com