Modularized beveling cutter with adjustable truncated edge

A modular, blunt edge technology, applied in the field of cutting tools, can solve the problems of inconvenient processing of double-sided bevels, inconvenient use, and inconvenient tool replacement, etc., to achieve the effect of better practicality, better use, and improved functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

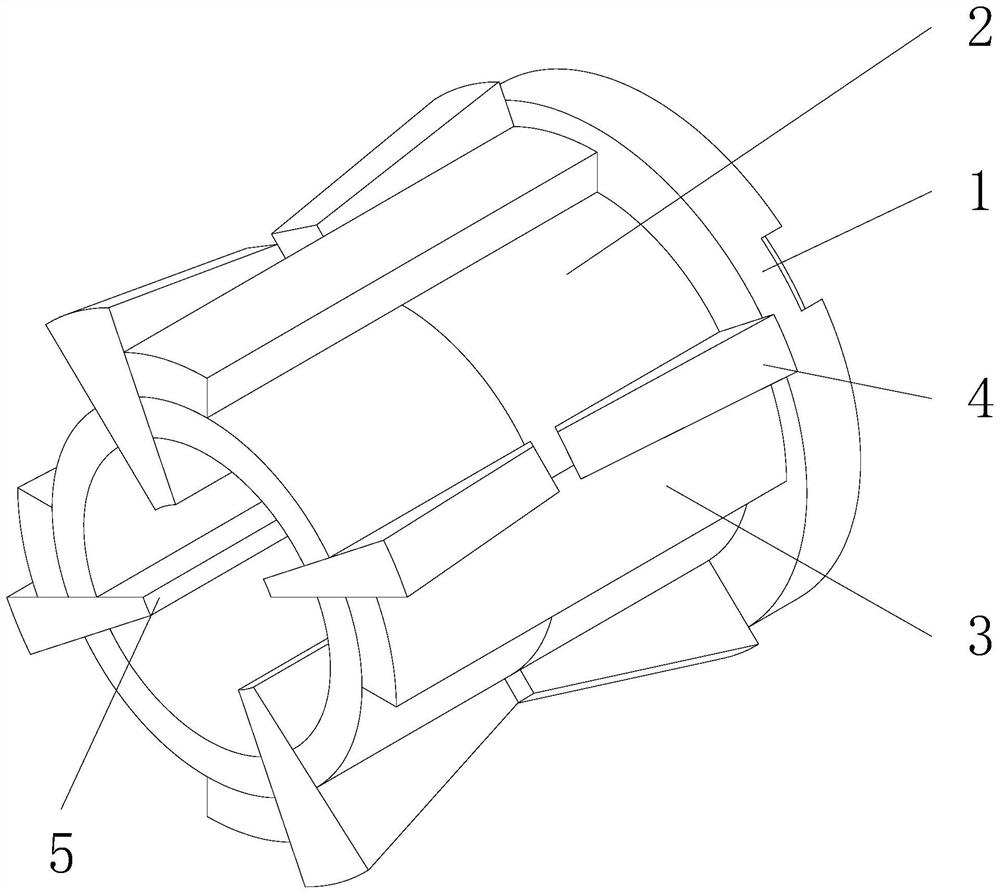

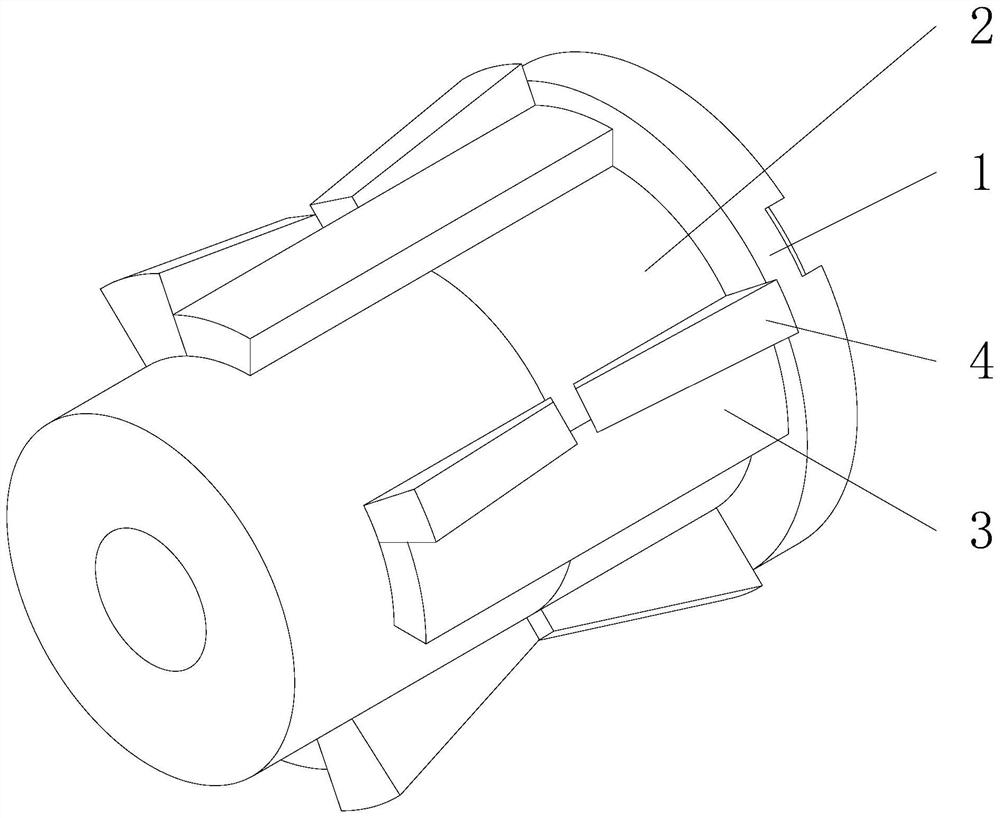

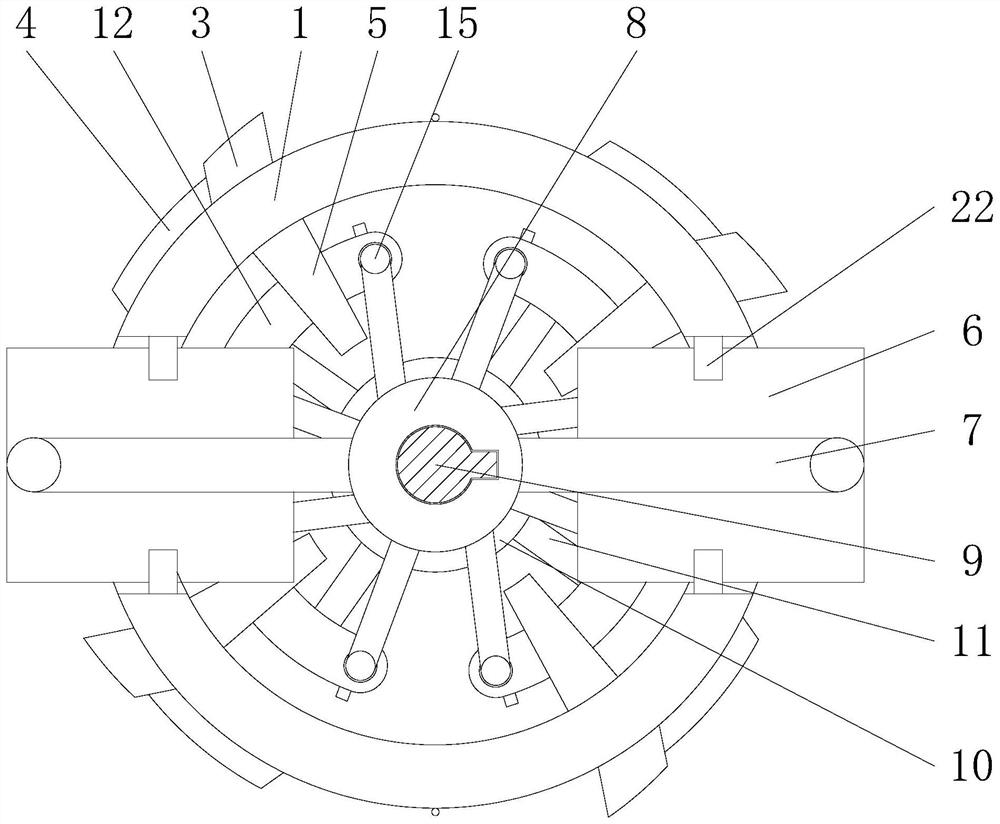

[0037] Such as Figure 1-8 As shown, a blunt edge adjustable modular bevel cutter includes a cutter head 1, a cylinder body 2, a knife seat 3 and a blade 4, the surface of the cutter head 1 is fixedly provided with a cylinder body 2, and the surface of the cylinder body 2 is installed with Knife seat 3, the side of knife seat 3 is provided with blade 4, and the front end of knife seat 3 is fixedly provided with fixed block 5, and the left and right sides of cutterhead 1 are all installed with connecting plate 6, and the surface of connecting plate 6 is fixedly provided with fixing bar 7. The front end of the fixed rod 7 is fixedly provided with a connecting cylinder 8, the rear side of the connecting cylinder 8 is provided with a motor 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com