Spraying device with replaceable nozzle and convenient to clean

A spraying device and nozzle technology, which is applied in the field of parts spraying, can solve the problems of affecting the health of operators, reducing the service life of the device, and affecting the use effect of the device, so as to improve the concentration of spraying, reduce costs, and improve the health of workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

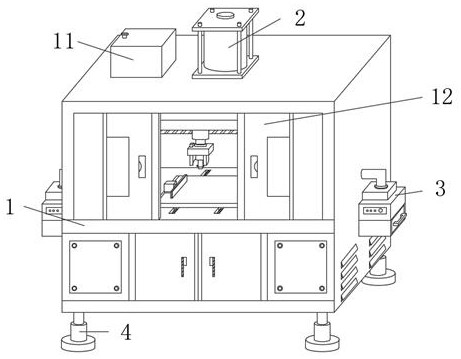

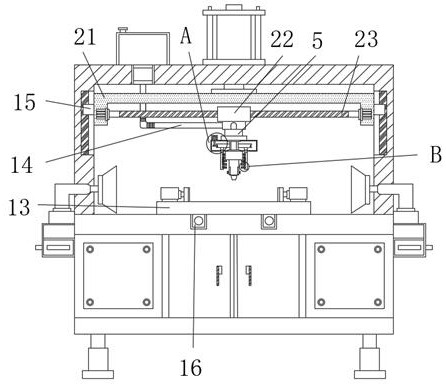

Embodiment 1

[0032] Embodiment 1: When the user needs to spray the parts, first add paint to the paint box 11, fix the workpiece to be sprayed on the clamping workbench 13, close the protective door 12, start the device, and the delivery hose 14 will The paint is transported to the conveying device 5, enters the fixed block structure 6 through the built-in conveying pipeline, removes impurities and foam in the paint through the filter screen 61, and improves the spraying quality of the paint, after the pressurized motor 62 drives the pressurized pump 63 Increase the pressure of the coating in the pressurized chamber 64 to increase the spraying distance. After the pressurization, the flow of the coating drives the hydraulic plate 72 to rotate, so that the threaded rod 71 rotates and drives the cleaning brush 73 to clean the inside of the draft tube structure 7 to prevent the coating from Adhered to the inner wall of the guide pipe structure 7, causing blockage, the paint passes through the f...

Embodiment 2

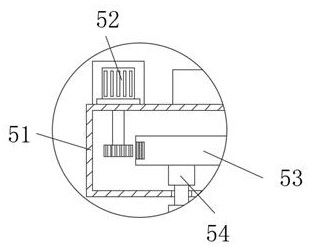

[0033] Embodiment 2: The cylinder structure 2 is used to push the support frame 21 to move under the action of the sliding device 15, and the driving screw 23 drives the movable block 22 to move left and right for uniform spraying, and the front and rear drive devices 16 drive the clamping table 13 to move back and forth. Thus, the workpiece is sprayed, the protective door 12 blocks the paint floating in the air, and the paint collector structure 3 collects the paint scattered inside, and transports the collected paint to the collection box 31, and then takes it out through the pulley 33 for further processing. Cleaning treatment, after a long time of use, drive the driven gear 53 to rotate through the driving gear 52, and the telescopic rod 54 pushes the connecting rod 55 to descend, so that the spring brush 56 can clean the surface of the spraying device comprehensively to avoid adhesion of paint in the air, Reduce the service life of the device and affect the use. The vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com