Anti-settling magneto-rheological vibration absorber for high-pressure hydraulic pipeline system and working process of anti-settling magneto-rheological vibration absorber

A hydraulic pipeline, anti-settling technology, applied in the direction of shock absorbers, shock absorbers, pipe components, etc., can solve the problem of not being able to absorb fluid pulsation and fluid impact well, to improve the settlement phenomenon, attenuate vibration and noise. , responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

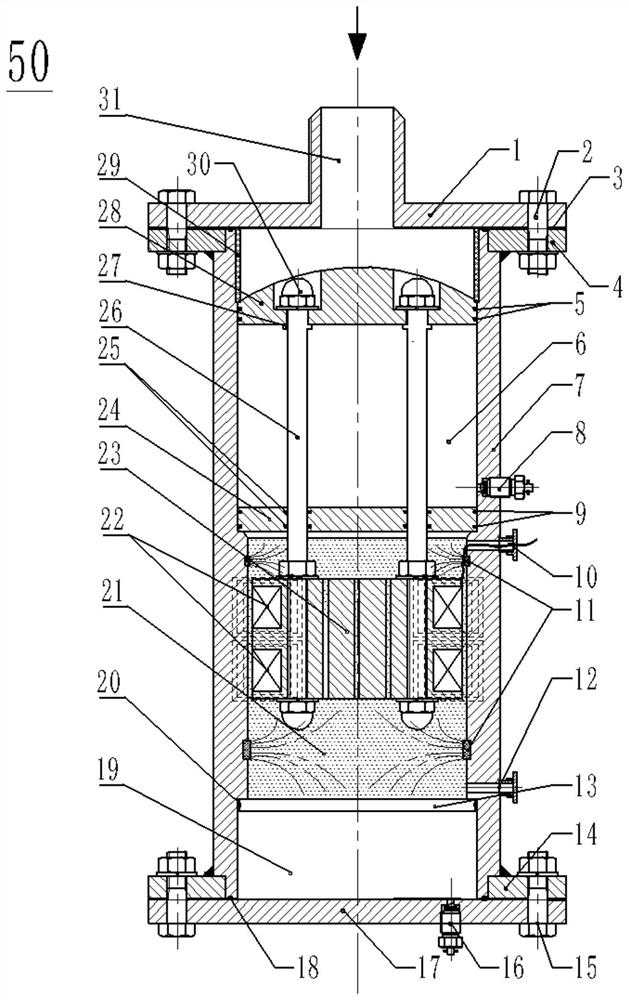

[0084] The rated pressure of a hydraulic system is 25MPa, the rated displacement is 18L / min, and the flow pulsation rate is 10%. It is required that the anti-settling magnetorheological damper can finally attenuate a certain pressure pulsation and achieve the effect of eliminating pressure pulsation. This implementation In the example, the inner diameter of the hydraulic pipeline is 10mm, and the length of the hydraulic pipeline is 1m. The model of the multi-plate vibrating fluid pulsation attenuator based on the mass-spring system is built by the modeling and simulation platform software AMESim.

[0085] The specific implementation process of the simulation analysis is as follows:

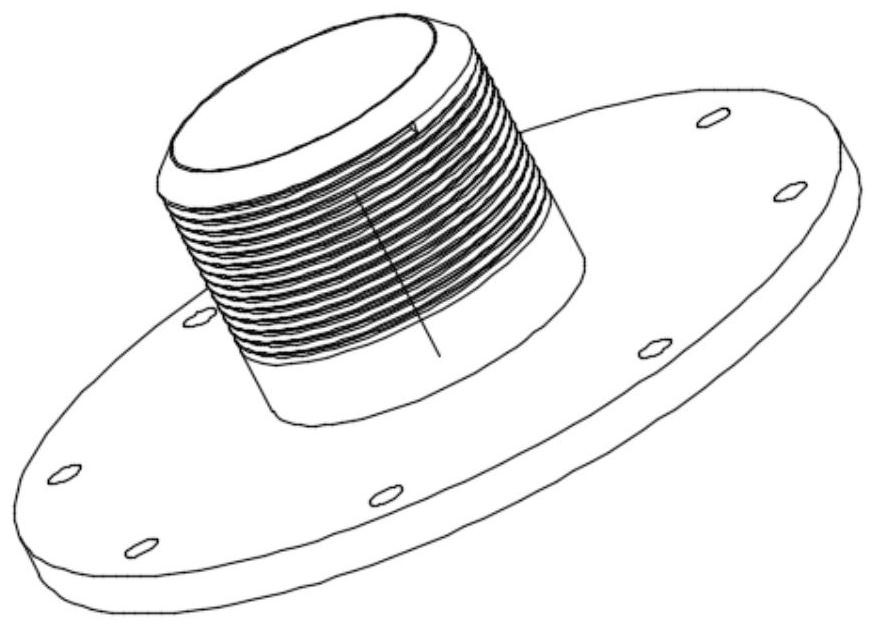

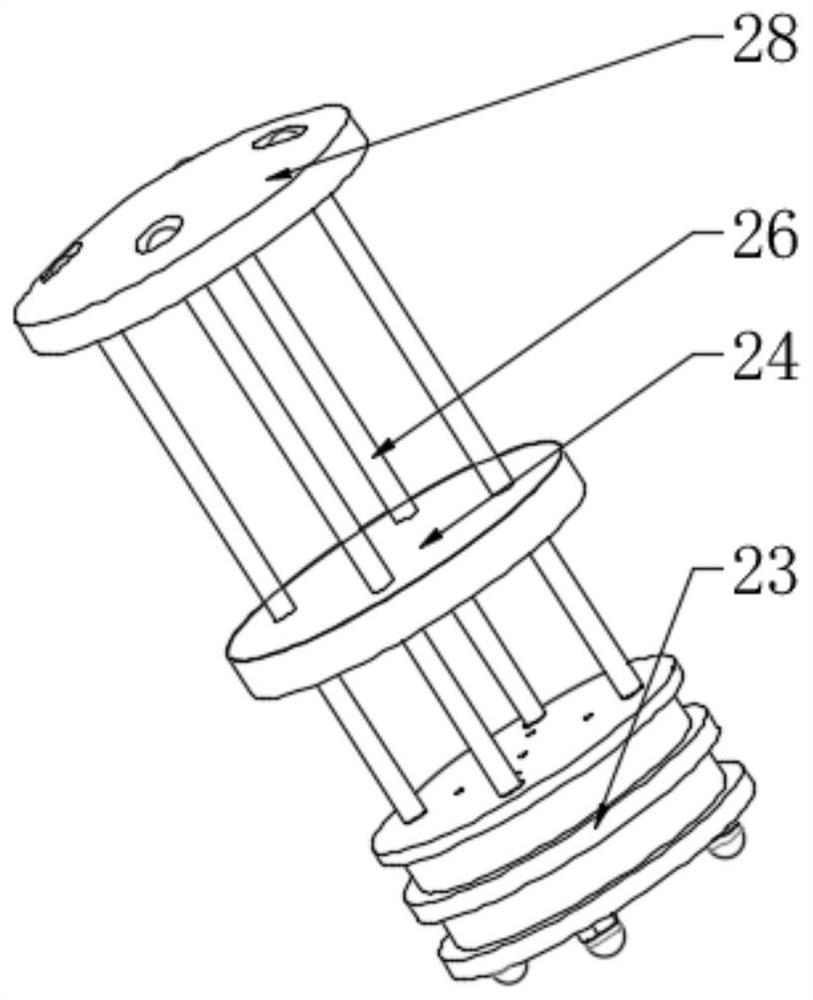

[0086] S1. According to the actual working conditions, the anti-sedimentation magnetorheological damper is designed to seal the bacteria-shaped piston mass, the gas pressure of the gas-filled cavity and the equivalent spring stiffness, the volume of the variable hydraulic cavity 105, and the coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com